This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

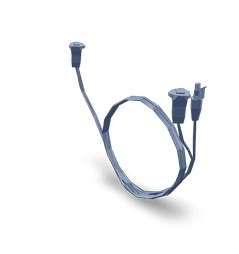

The Cummins 4964184 Wiring Harness is a specialized component designed for use in commercial trucks. Its purpose is to facilitate the electrical connections necessary for the operation of various truck systems. This wiring harness is significant in commercial truck operations as it ensures reliable and efficient electrical performance, contributing to the overall functionality and safety of the vehicle 1.

Basic Concepts of Wiring Harnesses

A wiring harness is an assembly of wires, connectors, and sometimes switches and relays that transmit electrical power and signals throughout a vehicle. It consists of multiple wires bundled together, often protected by a sheath, to prevent damage and reduce electromagnetic interference. Within a vehicle’s electrical system, the wiring harness plays a role by providing a structured and organized method for distributing power and signals to different components, ensuring they operate correctly and efficiently 2.

Role of the 4964184 Wiring Harness in Truck Operation

The 4964184 Wiring Harness is integral to the operation of a commercial truck. It connects various electrical components and systems, such as the engine control module, sensors, and other critical subsystems. By providing a reliable pathway for electrical signals and power, this wiring harness ensures that all connected systems can communicate and function as intended. Its integration with other systems enhances the truck’s performance, efficiency, and safety 3.

Key Features

The 4964184 Wiring Harness is characterized by its robust design and high-quality materials. It is engineered to withstand the demanding conditions of commercial truck environments, including vibrations, temperature fluctuations, and exposure to chemicals. The harness is constructed using durable wires and connectors, ensuring long-lasting performance. Additionally, it features a protective sheath that safeguards the wires from physical damage and environmental factors 4.

Benefits of Using the 4964184 Wiring Harness

Utilizing the 4964184 Wiring Harness offers several advantages in truck operations. It enhances reliability by providing secure and consistent electrical connections. This results in improved efficiency, as the electrical systems can operate without interruptions. Furthermore, the harness contributes to safety by ensuring that all electrical components function correctly, reducing the risk of malfunctions or failures that could compromise the truck’s operation 1.

Installation Considerations

When installing the 4964184 Wiring Harness, it is important to follow guidelines and best practices to ensure proper integration with the truck’s electrical system. This may involve disconnecting the battery to prevent electrical shocks, using appropriate tools for handling and securing the harness, and ensuring all connections are tight and correctly aligned. Special tools or prerequisites may be required, depending on the specific truck model and existing electrical setup 2.

Maintenance and Troubleshooting

To ensure the longevity and performance of the 4964184 Wiring Harness, regular maintenance is recommended. This includes inspecting the harness for signs of wear, damage, or corrosion, and cleaning the connections to prevent buildup that could affect performance. Common issues may include loose connections, damaged wires, or faulty connectors. Troubleshooting methods involve identifying the specific problem area, repairing or replacing damaged components, and ensuring all connections are secure and functioning correctly 3.

Compatibility and Usage

The 4964184 Wiring Harness is designed for specific types of trucks and engines. It is important to verify compatibility with the truck model and engine type to ensure proper fit and function. Usage guidelines may include specific installation procedures, maintenance schedules, and operational considerations to maximize the harness’s performance and lifespan 4.

Safety Precautions

When working with the 4964184 Wiring Harness, observing important safety measures is crucial. This includes ensuring the truck’s electrical system is de-energized before beginning any work to prevent electrical shocks. Additionally, handling the harness with care to avoid damage to the wires and connectors is important. Following proper electrical safety procedures and using appropriate personal protective equipment (PPE) will help ensure a safe working environment 1.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established itself as a trusted name in the commercial truck industry. The company is committed to quality and innovation, continually developing advanced technologies and solutions to meet the evolving needs of its customers. Cummins’ dedication to excellence is evident in its wide range of products, including the 4964184 Wiring Harness, which is designed to deliver reliable performance and enhance the efficiency and safety of commercial trucks 2.

Cummins Wiring Harness 4964184 Compatibility with Engine Models

The Cummins Wiring Harness 4964184 is designed to integrate seamlessly with a range of Cummins engine models, ensuring reliable electrical connectivity and performance. This wiring harness is compatible with the following engines:

QSK19 Series

- QSK19 CM2350 K105

- QSK19 CM2350 K114

- QSK19 CM850 MCRS

The QSK19 series engines, equipped with the 4964184 wiring harness, benefit from enhanced electrical management. This harness is engineered to handle the specific electrical demands of these models, ensuring optimal performance and reliability.

QSK38 Series

- QSK38 CM2150 MCRS

- QSK38 CM850 MCRS

The QSK38 series engines, including the CM2150 and CM850 variants, are also compatible with the 4964184 wiring harness. This compatibility ensures that these engines receive the necessary electrical support, maintaining their operational efficiency and longevity.

QSK50 and QSK60 Series

- QSK50 CM2150 MCRS

- QSK60 CM850 MCRS

The QSK50 and QSK60 series engines, specifically the CM2150 and CM850 models, are designed to work with the 4964184 wiring harness. This compatibility is crucial for these high-performance engines, as it ensures that the electrical systems are robust and capable of handling the demands of these powerful units.

By ensuring compatibility with these various engine models, the Cummins Wiring Harness 4964184 provides a reliable and efficient solution for maintaining the electrical integrity of Cummins engines across different series and configurations 3.

Role of Part 4964184 Wiring Harness in Engine Systems

The part 4964184 wiring harness is an integral component in the orchestration of various engine systems, ensuring seamless communication and operation among them.

Integration with the Fuel System

In the fuel system, the wiring harness connects the fuel filter to the electronic control module (ECM). This connection allows for the monitoring of fuel quality and flow, enabling the ECM to make real-time adjustments to fuel delivery based on engine demand and operating conditions.

Connection to the Electronic Control Module

The harness facilitates a robust link between the ECM and other engine components. It transmits data from sensors throughout the engine, allowing the ECM to execute precise control over engine functions such as ignition timing, fuel injection, and emissions control.

Role in Harnessing Electronic Signals

As a conduit for electronic signals, the wiring harness ensures that all engine components receive the correct signals at the right time. This is essential for the synchronized operation of the engine, particularly in modern engines where timing and precision are paramount.

Ensuring System Integrity

By providing a reliable pathway for electrical signals, the wiring harness helps maintain the integrity of the engine’s electronic systems. It protects against signal loss or interference, which could otherwise lead to engine misfires, reduced performance, or increased emissions.

In summary, the part 4964184 wiring harness is a foundational element in the engine’s electronic architecture, facilitating the efficient and effective operation of the fuel system, ECM, and overall engine performance 4.

Conclusion

The Cummins 4964184 Wiring Harness plays a crucial role in the electrical systems of commercial trucks, ensuring reliable and efficient operation of various components and subsystems. Its robust design, compatibility with specific engine models, and integration with critical systems like the fuel system and ECM highlight its importance in maintaining the performance, efficiency, and safety of commercial trucks. Regular maintenance, proper installation, and adherence to safety precautions are essential to maximize the benefits of this Cummins part.

-

BT Fijalkowski, Automotive Mechatronics Operational and Practical Issues Volume 1, Springer, 2011.

↩ ↩ ↩ -

Hamid Taghavifar and Aref Mardani, Offroad Vehicle Dynamics Analysis Modelling and Optimization, Springer, 2017.

↩ ↩ ↩ -

Harald Naunheimer, Bernd Bertsche, Joachim Ryborz, Wolfgang Novak, Automotive Transmissions Fundamentals Selection Design and Application, Springer Vieweg, 2011.

↩ ↩ ↩ -

Zhiyu Han, Simulation and Optimization of Internal Combustion Engines, SAE International, 2022.

↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.