This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

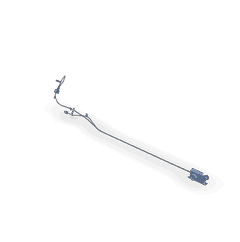

The Cummins 4967159 Wiring Harness is a specialized component designed for use in commercial trucks. It serves as an essential element in the vehicle’s electrical system, facilitating the connection between various electrical components and the truck’s power source. Its role is significant in ensuring the reliable operation of electrical systems within commercial trucks, contributing to overall vehicle performance and safety.

Basic Concepts of Wiring Harnesses

A wiring harness is an assembly of wires, connectors, and sometimes switches and relays that transmit electrical power and signals throughout a vehicle. It consists of multiple wires bundled together, often secured with tape or conduit, to protect against physical damage and electromagnetic interference. Within a vehicle’s electrical system, the wiring harness provides a structured and organized method for electrical distribution, ensuring that power and signals reach their intended destinations efficiently and safely 1.

Purpose of the 4967159 Wiring Harness

The Cummins 4967159 Wiring Harness is specifically designed to integrate with the electrical systems of commercial trucks. It facilitates the connection between the truck’s battery, engine control module (ECM), and various electrical components such as sensors, lights, and auxiliary devices. By providing a reliable pathway for electrical signals and power, the harness contributes to the efficient operation of the truck’s electrical systems, enhancing overall vehicle performance 2.

Key Features

The Cummins 4967159 Wiring Harness is characterized by several key features that enhance its performance and reliability. Its design incorporates high-quality materials resistant to corrosion and wear, ensuring durability in the demanding environments typical of commercial truck operations. The harness is engineered with precision to fit securely within the truck’s chassis, minimizing the risk of disconnection or damage. Additionally, it features robust connectors and terminals that provide secure and reliable electrical connections 3.

Benefits

The Cummins 4967159 Wiring Harness offers several advantages in truck operations. Its reliable design contributes to improved efficiency by ensuring consistent electrical connections, reducing the likelihood of system failures. The harness enhances safety by providing a structured and organized method for electrical distribution, minimizing the risk of short circuits or electrical fires. Furthermore, its durability and resistance to environmental factors contribute to the longevity of the truck’s electrical systems, reducing maintenance requirements and operational downtime 4.

Installation Process

Proper installation of the Cummins 4967159 Wiring Harness is crucial for ensuring its effective operation and longevity. The installation process involves several steps, including preparing the truck’s chassis for the harness, routing the wires according to the manufacturer’s guidelines, and securing the harness in place using appropriate fasteners. It is important to follow best practices during installation, such as avoiding sharp edges that could damage the wires and ensuring that all connections are secure and properly insulated. Common pitfalls to avoid include over-tightening connectors, which can lead to damage, and neglecting to protect the harness from physical damage or moisture.

Troubleshooting and Maintenance

Regular maintenance and troubleshooting are important for ensuring the continued performance of the Cummins 4967159 Wiring Harness. Routine inspections should be conducted to check for signs of wear, corrosion, or damage to the wires and connectors. Any issues identified during inspections should be addressed promptly to prevent further deterioration or system failures. Troubleshooting common issues may involve checking for loose connections, inspecting wiring for damage, and testing electrical components for proper operation. Following manufacturer guidelines for maintenance and troubleshooting can help ensure the longevity and reliability of the wiring harness.

Safety Considerations

When working with the Cummins 4967159 Wiring Harness, it is important to observe several safety guidelines and precautions. Electrical safety practices, such as ensuring the truck’s battery is disconnected before beginning work on the harness, are crucial for preventing electrical shocks or accidents. Additionally, handling procedures should be followed to avoid damaging the harness or its components. This includes using appropriate tools for installation and maintenance, avoiding excessive force when routing or securing the harness, and protecting the harness from physical damage or exposure to moisture.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for innovation, quality, and reliability in the commercial truck industry. The company offers a wide range of products and services designed to meet the diverse needs of its customers, from heavy-duty engines and powertrain solutions to aftermarket parts and services. Cummins’ commitment to excellence and customer satisfaction has made it a trusted partner for commercial truck operators worldwide.

Role of Part 4967159 Wiring Harness in Engine Systems

The 4967159 Wiring Harness is integral to the seamless operation of various engine systems by facilitating the connection between the Electronic Control Module (ECM) and other vital components. This harness ensures that electrical signals are accurately transmitted, enabling the ECM to monitor and adjust engine performance in real-time.

Integration with Electronic Control Module (ECM)

The primary function of the 4967159 Wiring Harness is to establish a robust connection between the ECM and the engine’s electrical components. This connection allows the ECM to receive data from sensors such as the Mass Air Flow (MAF) sensor, Oxygen (O2) sensor, and Manifold Absolute Pressure (MAP) sensor. The harness also enables the ECM to send commands to actuators like the fuel injectors, ignition coils, and variable valve timing (VVT) solenoids, ensuring precise control over fuel delivery, ignition timing, and valve operation.

Connection to Sensor Networks

The wiring harness plays a significant role in linking the ECM to an extensive network of sensors distributed throughout the engine system. These sensors provide critical data on engine temperature, airflow, and exhaust gas composition. The harness ensures that this data is transmitted without interference, allowing the ECM to make informed decisions that optimize engine efficiency and performance.

Power Distribution

In addition to signal transmission, the 4967159 Wiring Harness is responsible for distributing power to various electrical components within the engine system. This includes providing the necessary voltage to the ECM itself, as well as to components like the fuel pump, starter motor, and ancillary systems such as the air conditioning compressor. The harness is designed to handle varying current loads, ensuring that each component receives the appropriate amount of power for optimal operation.

Grounding and Signal Integrity

Effective grounding is essential for maintaining signal integrity within the engine’s electrical system. The 4967159 Wiring Harness incorporates multiple ground connections that help to stabilize voltage levels and reduce electrical noise. This ensures that the signals transmitted between the ECM and other components are clear and accurate, which is vital for the reliable operation of the engine.

Facilitation of Diagnostic Communication

The wiring harness also plays a role in facilitating diagnostic communication between the ECM and external diagnostic tools. By providing a pathway for data exchange, the harness allows mechanics to retrieve error codes, monitor live data streams, and perform various tests that aid in the diagnosis and resolution of engine issues. This capability is invaluable during routine maintenance and troubleshooting procedures.

Conclusion

In summary, the 4967159 Wiring Harness is a fundamental component that ensures the efficient and reliable operation of the engine’s electrical system. Its role in signal transmission, power distribution, and diagnostic communication underscores its importance in modern engine designs.

-

Vocational Vehicles and Applications, Michael Hilgers and Wilfried Achenbach, Springer Vieweg, 2021

↩ -

Offroad Vehicle Dynamics Analysis Modelling and Optimization, Hamid Taghavifar and Aref Mardani, Springer, 2017

↩ -

Road and Off-Road Vehicle Dynamics, Moustafa ElGindy and Zeinab ElSayegh, Springer Nature, 2023

↩ -

Auto Repair for Dummies: 2nd Edition, Deanna Sclar, For Dummies, 2008

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.