This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

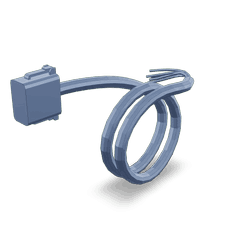

The Cummins 4998416 Wiring Loom is a specialized component designed for use in commercial trucks. It serves a significant role in the electrical system, ensuring that various electrical components function correctly and efficiently. Understanding its purpose and significance is vital for maintaining the overall performance and reliability of the vehicle.

Basic Concepts of Wiring Looms

A wiring loom is an assembly of electrical cables or wires bundled together and usually taped or otherwise bound for protection and organization. Within a vehicle’s electrical system, a wiring loom facilitates the transmission of electrical signals and power to various components, ensuring they operate as intended. The components of a wiring loom typically include wires, connectors, and protective coverings. These elements work together to manage the complex network of electrical connections required in modern vehicles 1.

Purpose of the 4998416 Wiring Loom

This Cummins part is specifically designed to integrate into the electrical system of a truck, providing a structured and protected pathway for electrical signals and power. It plays a role in connecting various electrical components, such as sensors, lights, and control units, ensuring they receive the necessary power and signals to function correctly. This wiring loom is tailored for specific applications within the truck’s electrical architecture, enhancing both the reliability and efficiency of the system 2.

Key Features

The 4998416 Wiring Loom boasts several key features that enhance its performance and durability. Its design incorporates high-quality materials that are resistant to wear, corrosion, and environmental factors, ensuring longevity. The loom is engineered to withstand the rigors of commercial truck operations, including exposure to vibrations, temperature fluctuations, and moisture. Additionally, it features precise wiring configurations and robust connectors that ensure secure and reliable connections.

Benefits of Using the 4998416 Wiring Loom

Utilizing this part offers several advantages. It contributes to improved reliability by providing a structured and protected pathway for electrical connections, reducing the risk of faults and failures. The loom enhances efficiency by ensuring that electrical signals and power are transmitted effectively throughout the truck’s systems. Moreover, it plays a role in enhancing safety by maintaining the integrity of electrical connections, which is crucial for the proper operation of safety-critical components 3.

Installation Process

Proper installation of the 4998416 Wiring Loom is crucial for ensuring its effectiveness. The process involves several steps: first, preparing the truck’s electrical system by ensuring all existing wiring is in good condition and properly routed. Next, the loom is carefully positioned and secured in place, following the manufacturer’s guidelines. Tools such as wire strippers, crimping tools, and electrical tape may be required. Each connection should be checked for security and correctness to ensure optimal performance.

Maintenance and Care

To ensure the longevity and optimal performance of the 4998416 Wiring Loom, regular maintenance is recommended. This includes periodic inspections to check for signs of wear, corrosion, or damage. Any issues should be addressed promptly to prevent further deterioration. Cleaning the loom and its connections can also help maintain its efficiency. Additionally, protecting the loom from physical damage and environmental factors will contribute to its durability.

Troubleshooting Common Issues

Common problems associated with wiring looms can include loose connections, damaged wires, and corrosion. Troubleshooting these issues involves identifying the specific problem area, which may require visual inspection and testing of electrical connections. Repairing or replacing damaged sections of the loom, securing loose connections, and cleaning corroded areas are effective steps to address these issues. Regular maintenance can help prevent many common problems.

Safety Considerations

When working with the 4998416 Wiring Loom, it is important to follow safety guidelines to prevent accidents and ensure safe operation. This includes wearing appropriate personal protective equipment, such as gloves and safety glasses. Ensuring the truck’s electrical system is de-energized before beginning work is crucial to avoid electrical shocks. Additionally, working in a well-ventilated area and avoiding contact with hazardous materials will contribute to a safe working environment.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration systems, and aftermarket parts. With a history spanning over a century, Cummins has established itself as a trusted name in the automotive industry, particularly in the production of heavy-duty truck components. The company’s commitment to innovation and quality has made it a preferred choice for commercial vehicle manufacturers and operators worldwide.

Cummins Engine Wiring Loom Part 4998416

The Cummins Wiring Loom part number 4998416 is a critical component designed to fit seamlessly with a variety of Cummins engines. This wiring loom is engineered to ensure reliable electrical connections and efficient power distribution across the engine’s systems. Below is a detailed description of how this part integrates with specific Cummins engines:

G5.9 CM558, G8.3 CM558, G855 CM558, GTA8.3 CM558, GTA855 CM558 (CM2358), G101

The Wiring Loom part 4998416 is compatible with the G5.9 CM558, G8.3 CM558, G855 CM558, GTA8.3 CM558, and GTA855 CM558 (CM2358) engines. These engines are part of the G-series and GTA-series, known for their robust performance and reliability in various industrial applications. The wiring loom ensures that all electrical components, including sensors, actuators, and control units, are properly connected and functioning. This is crucial for maintaining optimal engine performance and ensuring that all systems operate in harmony.

KTA19GC CM558, KTA38GC CM558

The KTA19GC CM558 and KTA38GC CM558 engines also benefit from the Wiring Loom part 4998416. These engines are part of the KTA series, which is designed for heavy-duty applications such as marine and stationary power generation. The wiring loom in these engines is essential for managing the complex electrical systems that support high-power output and durability. It ensures that the electrical connections are secure and can withstand the demanding conditions these engines operate in.

QSL9 G CM558

The QSL9 G CM558 engine is another model that utilizes the Wiring Loom part 4998416. This engine is known for its efficiency and reliability in various industrial and agricultural applications. The wiring loom plays a vital role in ensuring that all electrical components are correctly connected, which is essential for the engine’s smooth operation and longevity.

In summary, the Cummins Wiring Loom part 4998416 is a versatile and essential component that ensures reliable electrical connections across a range of Cummins engines. Whether used in the G-series, GTA-series, KTA-series, or QSL9 G engines, this wiring loom is designed to meet the specific needs of each engine model, ensuring optimal performance and durability.

Role of Part 4998416 Wiring Loom in Engine Systems

This part is an integral component in the electrical architecture of engine systems, facilitating seamless communication and power distribution among various subsystems.

Integration with Harness

The wiring loom interfaces directly with the engine harness, acting as a conduit for electrical signals and power. It ensures that all electrical components receive the necessary voltage and current, while also managing signal transmission for engine control modules (ECMs) and other electronic control units (ECUs).

Control Panel Wiring

In systems where a control panel is employed, the wiring loom plays a significant role in connecting the panel to the engine’s electrical system. This includes providing power to the control panel and enabling it to send and receive signals from the engine’s sensors and actuators. The loom ensures that the control panel can effectively monitor and adjust engine parameters in real-time.

Panel Connectivity

For engine systems that incorporate a panel, the wiring loom is responsible for establishing a robust connection between the panel and the engine’s electrical network. This connection allows for the display of diagnostic information, status updates, and operational data, enhancing the overall monitoring and control capabilities of the engine system.

Digital Display Integration

In modern engine systems equipped with digital displays, the wiring loom is essential for transmitting data from various sensors to the display unit. This allows operators to view real-time information such as engine performance metrics, diagnostic codes, and system statuses. The loom ensures that the digital display receives accurate and timely data, enabling informed decision-making and proactive maintenance.

Conclusion

The Cummins 4998416 Wiring Loom is a critical component in the electrical systems of commercial trucks and various Cummins engines. Its role in ensuring reliable electrical connections, efficient power distribution, and seamless communication among subsystems is essential for maintaining optimal engine performance and vehicle reliability. Proper installation, regular maintenance, and adherence to safety guidelines are crucial for maximizing the benefits of this part.

-

Owen C Duffy and Gus Wright, Fundamentals of Medium-Heavy Duty Commercial Vehicle Systems (Jones Bartlett Learning, 2016)

↩ -

D. K. Singh, Dictionary of Mechanical Engineering (Springer Nature, 2024)

↩ -

Michael Hilgers, Fuel Consumption and Consumption Optimization, Second Edition (Springer Nature, 2023)

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.