This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 5254229 Wiring Harness is a specialized component designed for use in commercial trucks. It serves as a part of the vehicle’s electrical system, facilitating the connection between various electrical components and ensuring the efficient transmission of electrical signals and power. Its role is significant in maintaining the operational integrity of commercial trucks, which rely heavily on their electrical systems for a range of functions, from engine management to lighting and communication systems.

Basic Concepts of Wiring Harnesses

A wiring harness is an assembly of wires, connectors, and sometimes switches and relays, designed to transmit electrical power or signals between different components within a vehicle. It is the nervous system of the vehicle, allowing for the coordination and operation of various electrical and electronic systems. The components of a wiring harness include insulated wires, connectors, terminals, and sometimes protective conduits or sheaths. These elements work together to ensure reliable and efficient electrical transmission while protecting the wires from physical damage and environmental factors 1.

Purpose of the 5254229 Wiring Harness

This Cummins part is specifically engineered to integrate with the electrical systems of commercial trucks. It plays a role in connecting the engine control module (ECM) with sensors, actuators, and other electrical components, ensuring that the engine and ancillary systems operate efficiently. This harness is designed to handle the high electrical demands of commercial truck applications, providing a robust and reliable connection that supports the vehicle’s performance and safety features 2.

Key Features

The 5254229 Wiring Harness is characterized by its robust design and the use of high-quality materials. It features durable insulation and protective sheathing to withstand the harsh conditions often encountered in commercial truck operations. The harness is also designed with precision-engineered connectors and terminals to ensure secure and reliable connections. Additionally, it may include unique characteristics such as enhanced corrosion resistance and flexibility to accommodate the dynamic movements and vibrations experienced by trucks in operation.

Benefits

The advantages of the 5254229 Wiring Harness include improved electrical efficiency, which can lead to better overall vehicle performance and fuel efficiency. Its design reduces the risk of short circuits and electrical failures, contributing to enhanced reliability. The harness is also built to withstand the rigors of commercial truck operations, providing durability and longevity even in harsh operating conditions.

Installation and Integration

When installing this part, it is important to follow guidelines and considerations to ensure proper integration with the truck’s existing electrical systems. Compatibility with various truck models should be verified to ensure seamless installation and operation. The harness should be integrated carefully to avoid any interference with other electrical components and to maintain the integrity of the vehicle’s electrical system.

Maintenance and Troubleshooting

To ensure optimal performance of the 5254229 Wiring Harness, regular maintenance is recommended. This includes inspecting the harness for signs of wear, corrosion, or damage and addressing any issues promptly. Common problems may include loose connections, damaged wires, or corroded terminals. Effective troubleshooting involves identifying the source of the issue and making the necessary repairs or adjustments to restore the harness’s functionality 3.

Safety Considerations

When working with the 5254229 Wiring Harness, it is important to observe safety protocols and precautions. Electrical safety practices, such as ensuring the vehicle’s battery is disconnected before beginning work, should be followed to prevent electrical shocks or short circuits. Proper handling procedures for the harness and its components are also crucial to avoid damage and ensure safe and effective operation.

Environmental Impact

The production, use, and disposal of the 5254229 Wiring Harness have environmental considerations. Efforts to minimize the environmental footprint may include the use of recyclable materials in its construction, designing for longevity to reduce the need for frequent replacements, and implementing responsible disposal practices. Cummins is committed to innovation and quality, which includes considering the environmental impact of its products.

Cummins Overview

Cummins is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and a commitment to quality, Cummins serves commercial, industrial, and automotive markets. The company’s product offerings include a wide range of engines, components, and systems designed to meet the demanding requirements of various applications, demonstrating a dedication to excellence and customer satisfaction.

Compatibility

This wiring harness is compatible with the following Cummins engines:

K-Series Engines

- K38

- K50

These K-series engines, known for their robust design and efficiency, benefit from the precise electrical connections provided by the 5254229 wiring harness. The harness is engineered to handle the specific electrical demands of these engines, ensuring smooth operation and reducing the risk of electrical faults.

QSK Engines

- QSK50 CM2150

- QSK50 CM2150 MCRS

- QSK60 CM850 MCRS

The QSK engines, which are part of Cummins’ high-performance line, also utilize the 5254229 wiring harness. This harness is tailored to meet the complex electrical requirements of these engines, providing a reliable and efficient power distribution system. The MCRS (Modular Component Retrofit System) variant ensures that the harness can be easily integrated into existing systems, enhancing the engine’s adaptability and performance.

Role in Engine Systems

The 5254229 Wiring Harness is an integral component in the electrical architecture of engine systems. It facilitates the seamless integration and operation of various engine components by providing a structured pathway for electrical signals and power.

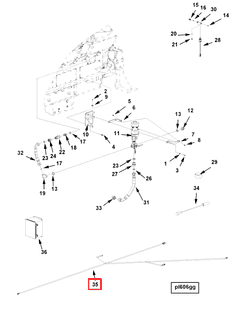

Integration with Engine Components

- Arrangement: The wiring harness is meticulously arranged to ensure that all electrical connections are secure and efficiently routed. This arrangement minimizes the risk of electrical interference and ensures that signals are transmitted without loss or distortion.

- Engine Lubrication Primer: The harness plays a significant role in the operation of the engine lubrication primer. It supplies the necessary electrical power and signals to the primer, enabling it to function correctly. This ensures that the engine receives adequate lubrication during startup, which is essential for reducing wear and tear on moving parts.

- Primer: In conjunction with the engine lubrication primer, the wiring harness ensures that the primer system receives consistent electrical input. This is vital for the primer to effectively prepare the engine for operation by ensuring that all lubrication pathways are primed and ready.

- Engine Lubricating System: The harness is also responsible for connecting various sensors and actuators within the engine lubricating system. It provides the electrical links needed for these components to communicate with the engine control unit (ECU), allowing for real-time monitoring and adjustment of lubrication levels.

Functional Synergy

The 5254229 Wiring Harness ensures that all these components work in harmony. By providing a reliable electrical connection, it allows the engine lubrication primer and other related systems to operate efficiently. This not only enhances the performance of the engine but also contributes to its longevity by ensuring that all systems are well-coordinated and functioning as intended.

Conclusion

The Cummins 5254229 Wiring Harness is a critical component for the electrical systems of commercial trucks, ensuring efficient and reliable operation of various engine components. Its robust design, compatibility with a range of Cummins engines, and the benefits it provides in terms of performance, reliability, and durability make it an essential part of the vehicle’s electrical architecture.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.