This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 5374881 Wiring Harness is a specialized component designed for use in commercial trucks. It serves as a vital part of the vehicle’s electrical system, facilitating the connection between various electrical components and the truck’s power source. This wiring harness is significant in ensuring the reliable operation of the truck’s electrical systems, contributing to overall vehicle performance and safety.

Basic Concepts of Wiring Harnesses

A wiring harness is an assembly of wires, connectors, and sometimes switches that transmit electrical power and signals between different components of a vehicle. It typically includes insulated wires bundled together, connectors for joining wires, and protective housing to shield the wires from physical damage and environmental factors. Within a vehicle’s electrical system, the wiring harness plays a role in distributing power from the battery to various electrical components, such as lights, sensors, and control units, ensuring they operate correctly 1.

Purpose of the 5374881 Wiring Harness

The Cummins 5374881 Wiring Harness is designed to integrate with the electrical systems of commercial trucks, providing a structured and organized method for electrical distribution. It connects critical components such as the engine control module (ECM), sensors, and actuators, enabling them to communicate and function as intended. This harness plays a role in enhancing the efficiency and reliability of the truck’s electrical system by ensuring stable and consistent power delivery to all connected components.

Key Features

The Cummins 5374881 Wiring Harness features a robust design that includes high-quality materials resistant to wear, corrosion, and environmental factors. It is constructed with durable insulation and protective housing to safeguard the wires from physical damage and exposure to the elements. Unique characteristics of this wiring harness may include custom-fit connectors for precise installation, enhanced conductivity for efficient power transmission, and a compact design to fit within the confined spaces of a truck’s engine compartment.

Benefits

The Cummins 5374881 Wiring Harness offers several benefits that contribute to the reliability, efficiency, and safety of truck operations. By providing a structured and organized method for electrical distribution, it helps reduce the risk of electrical faults and improves the overall performance of the truck’s electrical system. Its durable construction and protective features enhance the longevity of the wiring harness, reducing the need for frequent replacements and maintenance. Additionally, the efficient power transmission capabilities of this harness contribute to the optimal operation of the truck’s electrical components, supporting safe and reliable vehicle performance.

Installation Process

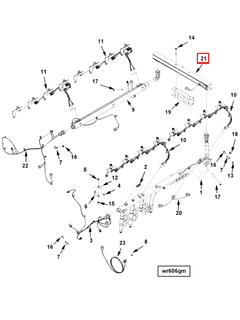

Installing the Cummins 5374881 Wiring Harness requires careful attention to detail and adherence to safety precautions. The process involves identifying the correct location for the harness within the truck’s engine compartment, routing the wires to avoid interference with other components, and securely connecting the harness to the appropriate electrical terminals. Tools required for installation may include wire cutters, crimping tools, and a multimeter for testing connections. Safety precautions include disconnecting the battery before beginning work to prevent electrical shocks and ensuring all connections are secure to avoid short circuits.

Troubleshooting Common Issues

Common issues with the Cummins 5374881 Wiring Harness may include loose connections, damaged wires, or faulty connectors. Troubleshooting steps involve visually inspecting the harness for signs of wear or damage, testing electrical connections with a multimeter to identify any faults, and repairing or replacing damaged components as necessary. Regular maintenance and inspections can help prevent many of these issues, ensuring the continued reliable operation of the truck’s electrical system.

Maintenance Tips

To ensure the longevity and optimal performance of the Cummins 5374881 Wiring Harness, regular maintenance is recommended. This includes periodic inspections for signs of wear, corrosion, or damage, cleaning the harness to remove dirt and debris that could affect electrical conductivity, and ensuring all connections are secure and free from corrosion. Additionally, protecting the harness from physical damage and environmental factors, such as moisture and extreme temperatures, can help maintain its integrity and performance.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and innovation in the commercial truck industry. The company offers a wide range of products and services designed to meet the diverse needs of its customers, from heavy-duty trucks to light-duty vehicles and power generation applications. Cummins’ commitment to excellence and customer satisfaction has made it a trusted name in the industry.

Cummins Engine Wiring Harness 5374881

The Cummins Wiring Harness part number 5374881 is a critical component designed to integrate seamlessly with a variety of Cummins engines. This wiring harness is engineered to ensure reliable and efficient electrical connectivity across different engine models, facilitating the smooth operation of various engine functions.

QSK60 and CM850 Engines

In the QSK60 and CM850 engines, the wiring harness 5374881 plays a pivotal role in managing the electrical systems. These engines are known for their robust performance and are often used in heavy-duty applications, such as marine and industrial settings. The harness is designed to handle the high electrical demands of these engines, ensuring that all sensors, actuators, and control units are properly connected and functioning. The harness is meticulously routed to avoid interference with other engine components, ensuring longevity and reliability.

MCRS Engines

The MCRS engines also benefit from the Cummins Wiring Harness 5374881. These engines are typically used in medium-duty applications, where reliability and efficiency are paramount. The wiring harness is tailored to meet the specific electrical requirements of the MCRS engines, ensuring that all electrical systems are integrated smoothly. This includes connections to the engine control module, sensors, and other critical components. The harness is designed to withstand the rigors of medium-duty operations, providing a durable and dependable solution for these engines.

Integration and Compatibility

The Cummins Wiring Harness 5374881 is designed with compatibility in mind, ensuring it can be integrated into various engine configurations without requiring extensive modifications. This versatility makes it an ideal choice for technicians and engineers working with multiple engine types. The harness is engineered to meet the stringent standards set by Cummins, ensuring high performance and reliability across different engine models.

Role of Part 5374881 Wiring Harness in Engine Systems

The 5374881 Wiring Harness is an integral component in the electrical architecture of engine systems, facilitating the seamless transmission of power and data between various subsystems. This harness is meticulously designed to interface with the Electronic Control Module (ECM) wiring, ensuring that the ECM receives accurate and timely data from sensors and other input devices scattered throughout the engine.

In operation, the 5374881 Wiring Harness connects to a multitude of engine components, including but not limited to, the fuel injectors, ignition coils, and various sensors such as the Mass Air Flow (MAF) sensor, Oxygen (O2) sensors, and Manifold Absolute Pressure (MAP) sensor. It acts as the nervous system of the engine, relaying critical information to the ECM, which in turn processes this data to make real-time adjustments to engine performance.

Moreover, the harness is responsible for distributing power to actuators and solenoids that control functions like fuel delivery, idle speed, and emissions systems. Its robust construction ensures durability under the harsh conditions present in an engine compartment, while its precise routing minimizes the risk of interference with moving parts or heat sources.

The integration of the 5374881 Wiring Harness with the ECM wiring is paramount for the ECM to execute its role effectively. The ECM relies on the data transmitted through this harness to modulate engine parameters such as fuel injection timing, ignition timing, and variable valve timing. Without a reliable wiring harness, the ECM would be unable to perform these functions with the precision required for optimal engine operation.

Conclusion

In summary, the 5374881 Wiring Harness is a fundamental element in the engine’s electrical system, ensuring that all components work in unison to deliver efficient and responsive performance. Its role in connecting the ECM to the engine’s various sensors and actuators is essential for the ECM to make informed decisions that enhance engine functionality and reliability.

-

Brach, R. Matthew. SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety. SAE International, 2023.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.