2883253

Rocker Top Level Assembly Lever

Cummins®

AVAILABLE

2 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

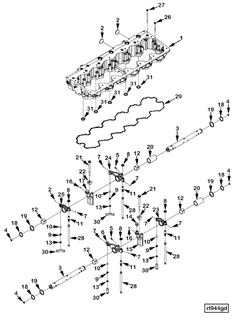

The Rocker Arm Assembly Level Lever, identified by part number 2883253, is a component manufactured by Cummins. This part is integral to the engine system, facilitating the operation of the valve train mechanism. Cummins, a well-established name in the automotive and heavy-duty truck industry, ensures that this component meets rigorous standards for performance and reliability.

Basic Concepts of Rocker Arm Assembly Level Lever

The Rocker Arm Assembly Level Lever operates on fundamental mechanical principles. It serves as a pivotal link in the valve train, transferring motion from the camshaft to the valves. This lever amplifies the camshaft’s motion, ensuring that the valves open and close with the precision required for optimal engine performance. Its interaction with other engine components, such as the camshaft and valve springs, is crucial for maintaining the engine’s efficiency and power output 1.

Purpose and Role in Truck Operation

In the context of a truck’s engine system, the Rocker Arm Assembly Level Lever plays a significant role. It ensures that the valves open and close at the correct times and with the appropriate force. This timing and force are vital for the engine’s combustion process, directly influencing the truck’s performance and fuel efficiency. By maintaining precise valve operation, this component contributes to the engine’s overall durability and reliability.

Key Features

The Rocker Arm Assembly Level Lever boasts several key features that enhance its functionality. It is typically constructed from high-strength materials to withstand the rigors of engine operation. Design elements such as precise machining and surface treatments ensure smooth operation and longevity. Additionally, any unique characteristics, such as specific geometry or coatings, are aimed at reducing friction and wear, thereby improving the component’s performance and lifespan.

Benefits

The benefits of the Rocker Arm Assembly Level Lever include improved engine performance, enhanced durability, and increased reliability. These advantages translate to tangible benefits for truck operators and fleet managers, such as reduced maintenance costs, extended engine life, and improved fuel efficiency. The component’s robust design and precise operation contribute to a more reliable and efficient engine, ultimately leading to better overall truck performance 2.

Installation Process

Installing the Rocker Arm Assembly Level Lever requires careful attention to detail and adherence to safety protocols. The process involves several steps, including preparing the engine compartment, aligning the lever with the camshaft and valves, and securing it in place. Necessary tools and equipment, such as torque wrenches and alignment tools, should be on hand. Safety precautions, including wearing protective gear and ensuring the engine is cool, are imperative to prevent injuries and ensure a successful installation.

Troubleshooting Common Issues

Common issues with the Rocker Arm Assembly Level Lever may include wear, misalignment, or failure to operate smoothly. Troubleshooting steps involve inspecting the lever for signs of damage or wear, checking alignment with the camshaft and valves, and ensuring that all fasteners are properly torqued. Solutions may range from simple adjustments to replacement of the lever. Proactive maintenance practices, such as regular inspections and lubrication, can help prevent these issues.

Maintenance Tips

To ensure the longevity and optimal performance of the Rocker Arm Assembly Level Lever, regular maintenance is crucial. This includes periodic inspections for signs of wear or damage, cleaning to remove any debris or buildup, and lubrication to reduce friction. Following the manufacturer’s recommended maintenance schedule and using high-quality lubricants will help maintain the component’s efficiency and reliability.

Cummins: Manufacturer Overview

Cummins is a renowned manufacturer with a rich history in the automotive and heavy-duty truck industry. The company is known for its commitment to quality, innovation, and customer satisfaction. Cummins’ reputation is built on a foundation of rigorous testing, advanced engineering, and a dedication to producing reliable and high-performing components. Their Rocker Arm Assembly Level Lever is a testament to their expertise and commitment to excellence in the industry.

Compatibility of Rocker Arm Assembly Level Lever (Part 2883253) with Cummins Engines

The Rocker Arm Assembly Level Lever, part number 2883253, manufactured by Cummins, is designed to fit a variety of Cummins engines. This part is integral to the proper functioning of the engine’s valve train system, ensuring that the rocker arms are correctly positioned and maintained.

ISX12 Series

- ISX12 CM2350 X102

- ISX12 G CM2180 EJ

- ISX12/ISX11.9 CM2250

The ISX12 series engines, including the ISX12 CM2350 X102, ISX12 G CM2180 EJ, and ISX12/ISX11.9 CM2250, are high-performance engines commonly used in heavy-duty applications. The Rocker Arm Assembly Level Lever is compatible with these engines, ensuring precise valve operation and maintaining engine efficiency.

ISZ13 Series

- ISZ13 CM2150 Z105

The ISZ13 CM2150 Z105 engine is part of the ISZ13 series, which is designed for medium-duty applications. The Rocker Arm Assembly Level Lever is engineered to fit this engine, providing the necessary adjustments for optimal valve timing and performance.

QSX11.9 Series

- QSX11.9 CM2250 ECF

The QSX11.9 CM2250 ECF engine is a mid-range engine known for its balance of power and fuel efficiency. The Rocker Arm Assembly Level Lever is compatible with this engine, ensuring that the rocker arms are properly aligned and functioning as intended.

QSZ13 Series

- QSZ13 CM2150 Z101

- QSZ13 CM2150 Z102

The QSZ13 series engines, including the QSZ13 CM2150 Z101 and QSZ13 CM2150 Z102, are designed for medium-duty applications. The Rocker Arm Assembly Level Lever is compatible with these engines, providing the necessary adjustments for maintaining proper valve operation and engine performance.

Z13 Series

- Z13 Z108G

The Z13 Z108G engine is part of the Z13 series, which is known for its reliability and durability in heavy-duty applications. The Rocker Arm Assembly Level Lever is compatible with this engine, ensuring that the rocker arms are correctly positioned and maintained for optimal engine performance.

Role of Part 2883253 Rocker Arm Assembly Level Lever in Engine Systems

The part 2883253 Rocker Arm Assembly Level Lever is an integral component in the operation of the valve train within an engine system. This lever is designed to transfer motion from the camshaft to the valves, ensuring precise and efficient valve operation.

Interaction with Other Components

-

Camshaft: The camshaft features lobes that rotate as the engine runs. As each lobe passes under the Rocker Arm Assembly Level Lever, it pushes against it, initiating movement.

-

Rocker Arm: The Rocker Arm Assembly Level Lever is a part of the rocker arm mechanism. When the camshaft lobe pushes the lever, it causes the rocker arm to pivot. This pivoting action is essential for transferring the motion to the valve.

-

Valve: The ultimate goal of the Rocker Arm Assembly Level Lever is to control the opening and closing of the valve. As the rocker arm pivots, it pushes down on the valve stem, opening the valve. When the lever moves away, spring pressure closes the valve.

-

Pushrod (in pushrod engines): In engines that utilize pushrods, the Rocker Arm Assembly Level Lever interacts with the pushrod to transmit motion from the camshaft to the rocker arm. The pushrod extends and retracts as the camshaft rotates, ensuring consistent valve operation.

-

Valve Spring: This spring applies constant pressure to keep the valve closed when not in operation. The interaction between the Rocker Arm Assembly Level Lever and the valve must overcome this spring pressure to open the valve.

-

Valve Seat: The valve seat is where the valve makes contact when it is closed. Proper operation of the Rocker Arm Assembly Level Lever ensures that the valve aligns correctly with the seat, promoting a seal that prevents combustion gases from escaping.

Summary of Functional Relationships

The Rocker Arm Assembly Level Lever acts as a mediator between the camshaft and the valve, ensuring that the valve opens and closes at the correct times. Its interaction with the rocker arm, pushrod (if applicable), and valve spring is essential for maintaining engine performance and efficiency. Each component relies on the precise movement facilitated by the lever to function correctly within the engine system.

Conclusion

The 2883253 Rocker Arm Assembly Level Lever is a critical component in the engine system, ensuring precise and efficient valve operation. Its compatibility with various Cummins engines highlights its versatility and importance in maintaining engine performance and reliability. Regular maintenance and proper installation are essential to maximize the benefits of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.