This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

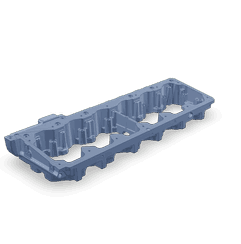

The Rocker Lever Housing part #2897183, manufactured by Cummins, is a crucial component in the valve train system of truck engines. This part plays a significant role in the operation of the valve train mechanism, ensuring precise and efficient valve operation. Understanding its function and significance can provide valuable insights into the overall performance and reliability of commercial trucks.

Basic Concepts and Functionality

The Rocker Lever Housing serves as a mounting point for rocker arms, which transfer motion from the camshaft to the valve stems. This transfer of motion is essential for the opening and closing of engine valves, which control the intake of air and fuel and the expulsion of exhaust gases 1. The housing ensures that the rocker arms are properly positioned and supported, allowing for precise and efficient valve operation.

Purpose of the Rocker Lever Housing

The primary role of the Rocker Lever Housing is to facilitate the transfer of motion from the camshaft to the valves. By providing a stable base for the rocker arms, it ensures that the valves open and close at the correct times and with the appropriate force. This precise timing and force are vital for the engine’s combustion process, directly influencing its efficiency and performance 2. The housing also helps in maintaining the alignment and integrity of the valve train components, contributing to the overall smooth operation of the engine.

Key Features

This Cummins part is designed with several key features that enhance its durability and performance. It is typically made from high-strength materials, such as cast iron or aluminum, to withstand the high temperatures and pressures within the engine compartment. The design includes precise machining to ensure accurate fitment and function. Additionally, the housing may feature integrated cooling channels or heat shields to manage thermal loads, further enhancing its longevity and reliability 3.

Benefits

Incorporating the Rocker Lever Housing part #2897183 into a truck engine can offer several advantages. Its robust construction and precise engineering contribute to improved engine efficiency and reliability. By ensuring optimal valve train operation, the housing helps maintain consistent engine performance over time. Furthermore, the enhanced durability of the housing can reduce the frequency of maintenance and repairs, leading to lower overall operating costs for commercial truck fleets 4.

Installation and Compatibility

Proper installation of the Rocker Lever Housing is crucial for ensuring its effectiveness and longevity. It is important to follow manufacturer guidelines to ensure compatibility with specific engine models. Preparatory steps may include cleaning the mounting surface and inspecting other valve train components for wear or damage. Careful alignment and torque specifications should be adhered to during installation to prevent issues such as misalignment or excessive wear.

Maintenance and Troubleshooting

Routine maintenance of the Rocker Lever Housing is important for ensuring its continued optimal performance. This may include regular inspections for signs of wear, corrosion, or damage. Cleaning the housing and its surrounding components can help prevent the buildup of debris that could interfere with valve train operation. Common issues that may arise include worn rocker arm pivot points or damaged housing surfaces, which can be addressed through timely replacement or repair.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and related technologies. With a history spanning over a century, Cummins has established a strong reputation for quality, reliability, and innovation within the commercial truck industry. Their product range includes engines and components that are designed to meet the demanding requirements of commercial applications, ensuring high performance and durability.

Compatibility of Rocker Lever Housing Part 2897183 with Cummins Engines

The Rocker Lever Housing part number 2897183, manufactured by Cummins, is designed to fit a variety of Cummins engine models. This part is integral to the engine’s valve train system, ensuring proper operation of the rocker levers and maintaining the engine’s performance.

ISX12 Series Engines

- ISX12 CM2350 X102

- ISX12 G CM2180 EJ

- ISX12/ISX11.9 CM2250

The Rocker Lever Housing part 2897183 is compatible with the ISX12 series engines, which include the ISX12 CM2350 X102, ISX12 G CM2180 EJ, and ISX12/ISX11.9 CM2250. These engines are known for their robust performance and are often used in heavy-duty applications. The part ensures that the rocker levers are securely housed and properly aligned, which is crucial for the engine’s smooth operation.

QSX Series Engines

- QSX11.9 CM2250 ECF

The QSX11.9 CM2250 ECF engine also benefits from the Rocker Lever Housing part 2897183. This engine is designed for applications requiring high power output and efficiency. The part’s design ensures that the rocker levers function correctly, contributing to the engine’s overall reliability and performance.

By using the Rocker Lever Housing part 2897183, technicians and fleet managers can ensure that their Cummins engines maintain optimal performance and longevity. This part is a critical component in the valve train system, and its proper installation is essential for the engine’s efficient operation.

Role of Part 2897183 Rocker Lever Housing in Engine Systems

The Rocker Lever Housing, identified by part number 2897183, is an integral component in the operation of engine systems, particularly in overhead valve (OHV) and overhead cam (OHC) engines. This housing encases the rocker arms and their associated components, providing a stable and secure environment for their function.

Interaction with Rocker Arms

Rocker arms are pivotal in transferring motion from the camshaft to the valves. The Rocker Lever Housing ensures that these arms are correctly positioned and supported. It maintains the precise alignment needed for the rocker arms to effectively translate the rotational motion of the camshaft into the linear motion required to open and close the valves.

Support for Valve Operation

In conjunction with the rocker arms, the Rocker Lever Housing plays a role in the overall valve operation. It helps in maintaining the integrity of the valve train by providing a consistent and reliable housing for the rocker arms. This stability is essential for the accurate timing and duration of valve events, which are critical for engine performance and efficiency.

Integration with Pushrods (in OHV Engines)

In overhead valve engines, the Rocker Lever Housing works in tandem with pushrods. The pushrods transmit motion from the camshaft, located in the engine block, to the rocker arms situated in the cylinder head. The housing ensures that the pushrods are correctly guided and supported, minimizing wear and ensuring smooth operation.

Contribution to Engine Durability

By providing a robust enclosure for the rocker arms and related components, the Rocker Lever Housing contributes to the durability and longevity of the engine. It protects these components from external contaminants and reduces the likelihood of mechanical failures, thereby enhancing the overall reliability of the engine system.

Facilitation of Maintenance and Adjustments

The design of the Rocker Lever Housing also aids in the maintenance and adjustment of the valve train components. It allows for easier access to the rocker arms and pushrods, facilitating routine checks, adjustments, and replacements. This accessibility is vital for maintaining optimal engine performance over time.

Conclusion

The Rocker Lever Housing part #2897183 by Cummins is a critical component in the valve train system of truck engines. Its robust construction, precise engineering, and compatibility with various Cummins engine models make it an essential part for ensuring optimal engine performance and reliability. Proper installation, routine maintenance, and understanding its role in the engine system are key to maximizing the benefits of this part.

-

Heywood, John. Internal Combustion Engine Fundamentals. McGraw-Hill Education, 2019.

↩ -

Halderman, James D. Automotive Principles: Diagnosis and Service. Prentice Hall, 2012.

↩ -

Eret, Angelina. Dynamic and Fatigue Assessment of Heavy-Duty Engine Valves. Springer Nature, 2024.

↩ -

Minaker, Bruce P. Fundamentals of Vehicle Dynamics and Modelling. John Wiley Sons, 2019.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.