This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

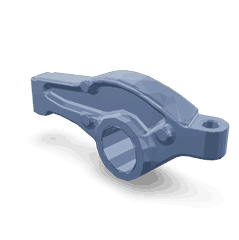

The Cummins 3025046 Rocker Lever is a component designed for heavy-duty truck engines, manufactured by Cummins Inc. This part is integral to the engine’s valve operation system, ensuring efficient and reliable performance. Cummins Inc., a well-established name in the automotive industry, is known for producing high-quality engine components that meet the demanding requirements of heavy-duty applications 1.

Basic Concepts of Rocker Levers

A rocker lever, also known as a rocker arm, is a mechanical component used in internal combustion engines to transfer motion. Its general function is to convert the pushrod’s linear motion into rotational motion to open and close the engine’s valves. Within an engine, the rocker lever operates by pivoting on a fulcrum, amplifying the motion from the camshaft to ensure precise valve actuation 2.

Role of the 3025046 Rocker Lever in Truck Engines

The 3025046 Rocker Lever plays a specific role in the operation of heavy-duty truck engines. It interacts with the camshaft, pushrods, and valves to ensure that the valves open and close at the correct times and with the appropriate force. This precise timing and force are crucial for the engine’s combustion process, directly influencing its performance and efficiency 3.

Key Features of the 3025046 Rocker Lever

The 3025046 Rocker Lever is designed with specific characteristics to enhance its performance and durability. It is typically made from high-strength materials to withstand the high stresses and temperatures within a heavy-duty engine. The design may include features such as a hardened contact surface to reduce wear and a precise geometry to ensure optimal valve actuation.

Benefits of Using the 3025046 Rocker Lever

Using the 3025046 Rocker Lever offers several advantages. It contributes to improved engine efficiency by ensuring precise valve timing and actuation. The robust design and high-quality materials used in its construction enhance the engine’s reliability and longevity, reducing the need for frequent replacements or repairs.

Installation and Integration

Proper installation of the 3025046 Rocker Lever is crucial for its effective operation within the engine. It should be installed according to the manufacturer’s guidelines, ensuring that all prerequisites are met and any special considerations are addressed. This may include checking for proper clearances, ensuring the surface is clean, and verifying that all related components are in good condition.

Troubleshooting Common Issues

Common problems associated with rocker levers can include wear, improper installation, or damage from debris. Addressing these issues may involve inspecting the lever for signs of wear or damage, ensuring it is correctly installed, and cleaning or replacing any damaged components. Regular maintenance and inspections can help identify and resolve these issues before they lead to more significant problems.

Maintenance Tips

Regular maintenance is key to ensuring the optimal performance and longevity of the 3025046 Rocker Lever. This includes periodic inspections for wear or damage, cleaning to remove any debris or buildup, and ensuring that all related components are in good working condition. Following the manufacturer’s maintenance schedule and guidelines can help prevent issues and extend the life of the rocker lever.

Cummins Inc. Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and innovation in the automotive industry. The company’s product range includes engines and components for on-highway, off-highway, and stationary applications, catering to a wide array of industries and needs.

Cummins Rocker Lever 3025046 in Engine Applications

The Cummins Rocker Lever 3025046 is a critical component in several engine configurations, ensuring the proper operation of the valve train. This part is integral to the engine’s performance and longevity, facilitating the movement of the valves in synchronization with the camshaft.

K19 Engines

The K19 engine series is one of the many applications where the Rocker Lever 3025046 is utilized. This engine is known for its robust design and reliability, often used in heavy-duty applications. The Rocker Lever in this engine ensures that the valves open and close at the correct times, which is essential for maintaining engine efficiency and performance.

Grouping of Applications

The Rocker Lever 3025046 is not limited to the K19 engine series. It is also compatible with other Cummins engines that share similar design principles and valve train mechanisms. The commonality in design allows for the interchangeability of this part across various engine models, simplifying maintenance and repair processes.

Importance in Engine Operation

The Rocker Lever’s role in the engine cannot be overstated. It acts as an intermediary between the camshaft and the valve, translating the rotational motion of the camshaft into the linear motion required to open and close the engine’s valves. This precise movement is crucial for the engine’s overall performance, ensuring that the air-fuel mixture is properly managed throughout the engine’s operating cycle.

Compatibility and Interchangeability

The design of the Cummins Rocker Lever 3025046 allows it to be used across multiple engine models, providing a level of interchangeability that benefits both manufacturers and end-users. This compatibility ensures that the same part can be used in different engines, reducing the need for multiple spare parts and simplifying inventory management.

Part 3025046 Rocker Lever Component Usage

The Rocker Lever, identified by part number 3025046, is an essential component in the operation of various engine systems. It is strategically positioned to interact with several key parts within the engine assembly.

Interaction with the Valve Train

The Rocker Lever is integral to the valve train mechanism. It is mounted on the base of the engine and is connected to the camshaft via pushrods or directly through overhead cam configurations. Its primary function is to transfer motion from the camshaft to the valves, ensuring precise timing and efficient operation of the intake and exhaust processes.

Connection to the Camshaft

In engines utilizing a pushrod design, the Rocker Lever receives motion from the camshaft through the pushrods. This motion is then amplified and transferred to the valves. In overhead cam (OHC) engines, the Rocker Lever may be directly actuated by the camshaft lobes, providing a more direct and potentially more efficient transfer of motion.

Role in Valve Actuation

The Rocker Lever plays a significant role in actuating the valves. It ensures that the valves open and close at the correct times and with the appropriate force. This is achieved through its interaction with the valve stem, where it applies the necessary force to overcome spring tension and facilitate the opening and closing of the valve.

Integration with the Engine Base

The base of the engine provides the mounting point for the Rocker Lever. This base must be precisely machined to ensure proper alignment and operation of the Rocker Lever. Any deviation in the base’s surface can lead to misalignment, affecting the performance and longevity of the valve train components.

Interaction with Other Components

Beyond its direct role in valve actuation, the Rocker Lever also interacts with other components such as valve springs, valve keepers, and valve seals. These interactions are vital for maintaining the integrity and performance of the valve train system. The Rocker Lever must be designed to withstand the forces exerted by these components while ensuring smooth and reliable operation.

Conclusion

In summary, the Rocker Lever (part 3025046) is a key component in the engine’s valve train system, facilitating the transfer of motion from the camshaft to the valves and ensuring the efficient operation of the engine. Its precise interaction with the camshaft, valve train, and engine base is essential for the overall performance and reliability of the engine system.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.