This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

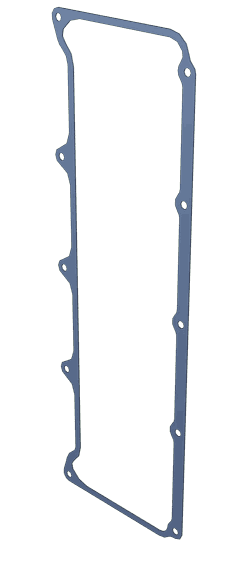

The Rocker Lever Housing Gasket, identified by part number 3026315, is a component manufactured by Cummins. This gasket ensures the integrity of seals within the rocker lever housing in the engine system. Cummins, a reputable manufacturer in the engine components industry, produces this gasket to meet high standards of quality and performance 1.

Basic Concepts

The Rocker Lever Housing Gasket is positioned within the engine’s valve train system, interfacing between the rocker lever housing and the cylinder head. This gasket facilitates the proper functioning of the rocker arms by providing a seal that prevents oil and other fluids from leaking into areas where they could cause damage or reduce efficiency. Its placement and interaction with other components are vital for maintaining the engine’s overall performance 2.

Function and Operation

The Rocker Lever Housing Gasket operates by creating a barrier that maintains seal integrity within the engine system. It ensures that pressurized oil, which lubricates the rocker arms, remains contained within the housing. This containment prevents oil from entering the combustion chamber or other sensitive areas, thereby maintaining engine efficiency and reliability. The gasket’s ability to form a tight seal is crucial for the proper operation of the valve train system 3.

Purpose of the Rocker Lever Housing Gasket

The specific role of the Rocker Lever Housing Gasket in a truck engine is to contribute to the overall performance and efficiency of the engine. By ensuring that the rocker arms are properly lubricated and that no oil leaks occur, the gasket helps maintain the engine’s operational integrity. This results in smoother valve operation, reduced wear on components, and enhanced engine reliability over time.

Key Features

The Rocker Lever Housing Gasket is designed with several key features that enhance its performance. It is typically made from high-quality materials that offer durability and resistance to oil and heat. The gasket’s design ensures a precise fit within the engine, providing a reliable seal. Additionally, it may incorporate features such as reinforced edges or multi-layered construction to improve its sealing capabilities and longevity.

Benefits

Using the Rocker Lever Housing Gasket offers several benefits. It contributes to improved engine reliability by preventing oil leaks, which can lead to decreased performance and increased wear on engine components. The gasket also reduces maintenance requirements by ensuring that the valve train system operates efficiently. Furthermore, it enhances overall engine performance by maintaining proper lubrication and seal integrity within the rocker lever housing.

Installation Process

Proper installation of the Rocker Lever Housing Gasket involves several steps. First, the cylinder head and rocker lever housing must be thoroughly cleaned to remove any old gasket material or debris. The new gasket should then be carefully positioned between the housing and the cylinder head. It is important to ensure that the gasket is aligned correctly and that no portions are folded or misaligned. Once in place, the rocker lever housing can be secured, taking care not to over-tighten the fasteners, which could damage the gasket.

Troubleshooting Common Issues

Common problems with the Rocker Lever Housing Gasket may include oil leaks or gasket failure. If an oil leak is detected, the first step is to inspect the gasket for signs of wear or damage. If the gasket appears intact, the issue may lie elsewhere, such as with the fasteners or mating surfaces. If the gasket is damaged, it should be replaced. Ensuring that the mating surfaces are clean and free of debris before installation can help prevent future issues.

Maintenance Tips

To ensure optimal performance and longevity of the Rocker Lever Housing Gasket, regular maintenance is recommended. Inspecting the gasket during routine engine maintenance can help identify any signs of wear or damage early. Additionally, ensuring that the cylinder head and rocker lever housing are clean and free of debris before reinstalling the gasket can contribute to its longevity. Following the manufacturer’s recommended inspection intervals and maintenance procedures will help maintain the gasket’s effectiveness.

Cummins Overview

Cummins is a well-established manufacturer with a strong reputation in the engine components industry. The company has a history of innovation and commitment to quality, producing a wide range of engine parts that are designed to meet the demanding requirements of modern engines. Cummins’ dedication to research and development ensures that their products, including the Rocker Lever Housing Gasket, are at the forefront of technology and reliability in the industry.

Cummins Rocker Lever Housing Gasket 3026315 Compatibility

The Cummins Rocker Lever Housing Gasket 3026315 is designed to ensure a proper seal between the rocker lever housing and the engine block. This gasket plays a vital role in preventing oil leaks and maintaining the integrity of the engine’s lubrication system.

V903 Engine Series

For the V903 engine series, the Rocker Lever Housing Gasket 3026315 is specifically engineered to fit seamlessly within the engine’s architecture. This gasket is essential for maintaining the engine’s performance and longevity by preventing oil from leaking out of the rocker lever housing. Its precise fit ensures that the gasket can withstand the high pressures and temperatures typically encountered in engine operation.

The V903 engine series, known for its robust design and efficiency, relies on components like the Rocker Lever Housing Gasket 3026315 to maintain operational integrity. The gasket’s design accommodates the unique contours and specifications of the V903 engine, ensuring a reliable seal that can endure the rigors of continuous use.

Application Across Cummins Engines

While the V903 engine series is a primary focus, the Rocker Lever Housing Gasket 3026315 is also compatible with other Cummins engines that share similar design characteristics. Cummins’ engineering philosophy emphasizes the use of standardized components across various engine models to simplify maintenance and repair processes. This approach ensures that technicians and operators can rely on a consistent set of parts across different engine types, facilitating easier inventory management and reducing downtime.

The gasket’s compatibility extends to other Cummins engines that feature similar rocker lever housing designs, ensuring that the same high-quality sealing performance can be achieved across a range of engine models. This standardization is a testament to Cummins’ commitment to quality and reliability in their engine components.

Role of Part 3026315 Rocker Lever Housing Gasket in Engine Systems

The part 3026315 Rocker Lever Housing Gasket is an essential component in ensuring the integrity and efficiency of various engine systems. Its primary function is to create a seal between the rocker lever housing and adjacent components, preventing oil and coolant leaks while maintaining proper pressure within the engine.

Integration with Engine Components

-

Base Parts and Engine Gasket Set:

- The Rocker Lever Housing Gasket works in conjunction with the base parts and the engine gasket set to ensure a comprehensive seal across the engine. This is particularly important in maintaining the structural integrity of the engine block and preventing any fluid leaks that could lead to engine damage.

-

Kit and PDC (Powertrain Control Module):

- When installed as part of a kit, the gasket ensures that all components, including the PDC, operate within optimal conditions. The PDC relies on stable engine conditions to deliver precise control signals, and the gasket helps maintain those conditions by ensuring no fluid leaks disrupt the engine’s performance.

-

RKR Lev Ratio Conv. Kit:

- In systems where a rocker lever ratio conversion kit is used, the gasket plays a vital role in sealing the modified rocker lever housing. This ensures that the conversion does not introduce any leaks, allowing the new ratio to function effectively without compromising engine seals.

-

Turbo Engine Components and Turbocharger Conversion Kit:

- For turbocharged engines, the Rocker Lever Housing Gasket is critical in maintaining the seal in high-pressure environments. When converting an engine to a turbocharged setup, the gasket must be correctly installed to handle the increased pressures and temperatures, ensuring the turbocharger operates efficiently.

-

Overhaul Gasket Set and Upper Engine Gasket Kit/Set:

- During an engine overhaul, the Rocker Lever Housing Gasket is often replaced as part of the overhaul gasket set or upper engine gasket kit/set. This ensures that all upper engine components, including the rocker housing and its mounting, are properly sealed, contributing to the overall reliability and performance of the overhauled engine.

-

Rocker Housing and Rocker Housing Mounting:

- The gasket is specifically designed to fit between the rocker housing and its mounting surface. This precise fit is essential for preventing oil from escaping, which could otherwise lead to reduced lubrication and increased wear on moving parts.

-

Single Head Gasket Set:

- In engines utilizing a single head gasket set, the Rocker Lever Housing Gasket complements this setup by providing an additional layer of sealing. This is particularly important in multi-cylinder engines where consistent sealing across all cylinders is necessary for balanced performance.

-

Upper Engine Components:

- The gasket interacts with various upper engine components, including the rocker arms and valve train. By ensuring a tight seal, it helps maintain consistent oil pressure and prevents contamination of the combustion chamber, which is essential for optimal engine operation.

Conclusion

In summary, the part 3026315 Rocker Lever Housing Gasket is a fundamental component in the sealing strategy of engine systems, working in harmony with other gaskets and components to ensure the engine operates smoothly and efficiently.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.