This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Rocker Lever Socket 3085980, a component manufactured by Cummins, is essential for the efficient operation of commercial truck engines. This part is integral to the engine’s valve train system, facilitating the transfer of motion from the pushrod to the valve via the rocker arm 1.

Basic Concepts

The Rocker Lever Socket operates on principles of mechanical leverage and motion transfer. It interfaces with the rocker arm, allowing it to pivot and transfer motion from the pushrod to the valve. This motion is critical for the opening and closing of the engine’s valves, which control the intake of air and fuel and the exhaust of combustion gases 2.

Purpose and Function

This Cummins part plays a pivotal role in the operation of a truck’s engine. It ensures that the valves open and close at the precise moments required for optimal engine performance. The socket’s design allows for smooth and efficient operation, minimizing wear and ensuring reliable valve actuation 1.

Key Features

The Rocker Lever Socket 3085980 is characterized by several key features that enhance its performance and durability. It is typically made from high-quality materials, such as hardened steel, to withstand the rigors of engine operation. The design includes precise tolerances to ensure a snug fit with the rocker arm and pushrod, reducing the likelihood of wear or failure. Additionally, the socket may feature unique attributes such as enhanced lubrication channels or specialized coatings to further improve its longevity and performance 3.

Benefits

The use of the Rocker Lever Socket 3085980 offers several advantages. Its robust construction and precise engineering contribute to improved engine efficiency and reliability. By ensuring smooth and consistent valve operation, the socket helps maintain optimal engine performance. Furthermore, its durable design enhances the longevity of the component, reducing the need for frequent replacements and contributing to overall vehicle reliability 1.

Installation and Maintenance

Proper installation of the Rocker Lever Socket 3085980 is crucial for ensuring optimal performance. Installation guidelines typically include torque specifications to ensure the socket is securely fastened without over-tightening, which could lead to damage. Alignment procedures are also important to guarantee that the socket operates within the designed parameters. Regular maintenance, such as periodic inspection for wear and proper lubrication, is recommended to ensure the socket continues to function effectively over time 2.

Troubleshooting

Common issues associated with the Rocker Lever Socket 3085980 may include wear, misalignment, or failure due to material fatigue. Symptoms of these issues can manifest as engine misfires, reduced performance, or unusual noises from the valve train. Recommended troubleshooting steps include visual inspection for signs of wear or damage, performing diagnostic tests to assess valve operation, and implementing corrective actions such as replacement or realignment as necessary 3.

Compatibility with Cummins Engines

The Rocker Lever Socket part 3085980 is designed to fit seamlessly within a range of Cummins engines. This part is crucial for the proper functioning of the engine’s valve train system, ensuring that the rocker levers operate smoothly and efficiently.

- QSK19 Series: QSK19 CM500, QSK19G

- QSK45 Series: QSK45 CM500

- QSK50 and QSK60 Series: QSK50 CM2350 K108, QSK60 CM500, QSK60 CM850 MCRS, QSK60 G CM2358 K110, QSK60G

- QSK95 Series: QSK95 CM2350 K111, QSK95 CM2350 K113

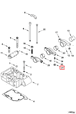

Role in Engine Systems

The Part 3085980 Rocker Lever Socket is an integral component within the rocker lever assembly of an engine system. It interfaces directly with the rocker lever, facilitating the transfer of motion from the camshaft to the valve. This socket is designed to fit precisely onto the rocker lever, ensuring a secure connection that allows for efficient and smooth operation of the valve train.

In the rocker lever assembly, the socket plays a key role in maintaining the alignment and integrity of the rocker lever’s movement. It supports the rocker lever as it pivots, which is essential for the accurate timing and operation of the engine’s valves. The socket must be robust enough to withstand the continuous stress and high temperatures within the engine compartment while providing a stable mount for the rocker lever.

When integrated into the rocker lever top-level assembly shaft, the socket ensures that the shaft can rotate smoothly without undue friction or wear. This is particularly important in high-performance engines where precision and reliability are paramount. The socket’s design allows for minimal play, which is vital for maintaining the precise valve clearances necessary for optimal engine performance.

In the context of the rocker top-level assembly lever, the socket contributes to the overall stability and durability of the assembly. It helps in distributing the forces exerted by the camshaft across the rocker lever, reducing the risk of component failure under high stress conditions. This is especially relevant in engines that operate at high RPMs, where the forces on the valve train are significantly greater.

Furthermore, within the rocker lever kit, the socket is often a replacement or upgrade part. Its compatibility with various rocker lever designs makes it a versatile component in maintenance and performance upgrade scenarios. Engineers and mechanics rely on the socket’s precise fit and function to ensure that the rocker lever kit performs as intended, enhancing the engine’s efficiency and reliability.

Conclusion

The Part 3085980 Rocker Lever Socket is a fundamental component that ensures the proper function and durability of the rocker lever assembly within engine systems. Its role in facilitating smooth and precise motion transfer is essential for the overall performance and longevity of the engine.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.