This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3092513 Rocker Arm Lever is a component designed for use in heavy-duty truck engines. It plays a role in the operation of these engines by facilitating the movement of valves, which is necessary for the intake and exhaust processes. This component’s design and function are integral to maintaining the efficiency and performance of heavy-duty trucks.

Basic Concepts of Rocker Arm Levers

A rocker arm lever is a mechanical device within an engine that operates to transfer motion from the camshaft to the valves. It acts as a fulcrum, allowing the camshaft to push on one end of the rocker arm, which then lifts the valve at the opposite end. This mechanism ensures that the valves open and close at precise intervals, which is necessary for the engine’s combustion process 1.

Purpose of the 3092513 Rocker Arm Lever

This Cummins part is specifically engineered to enhance the valve train system’s functionality in Cummins engines. By providing a reliable means of transferring motion from the camshaft to the valves, it contributes to the engine’s overall performance and efficiency. This component ensures that the valves operate smoothly and consistently, which is vital for the engine’s power output and fuel efficiency.

Key Features

The 3092513 is characterized by its robust design and high-quality materials. It is manufactured with precision to ensure durability and performance. The lever’s material composition is chosen for its strength and resistance to wear, while design enhancements may include features that reduce friction and improve operational efficiency. These characteristics contribute to the lever’s longevity and reliability in demanding engine environments.

Benefits

The advantages of the 3092513 include improved engine efficiency, enhanced reliability, and increased longevity. By ensuring smooth and precise valve operation, this component can contribute to better fuel economy and overall engine performance. Its durable construction also means that it can withstand the rigors of heavy-duty truck operation, providing consistent performance over time.

Installation and Compatibility

Proper installation of the 3092513 is crucial for ensuring it functions correctly within the engine assembly. It is designed to be compatible with specific Cummins engine models, and following the manufacturer’s guidelines for installation is important to maintain engine performance and safety. Ensuring the lever is correctly fitted will help prevent issues related to valve operation and engine efficiency.

Troubleshooting and Maintenance

Regular maintenance and inspection of the 3092513 are important for identifying potential issues such as wear and tear. Routine checks can help ensure the lever continues to operate smoothly and efficiently. If signs of damage or excessive wear are detected, it may be necessary to replace the lever to maintain engine performance. Effective troubleshooting involves understanding the symptoms of a failing rocker arm lever and taking appropriate action to address any issues.

Performance Enhancements

Upgrading or modifying the rocker arm lever system can have a significant impact on engine performance. Aftermarket options may offer improvements in material quality, design, or functionality that can enhance engine efficiency, power output, and reliability. These enhancements can be particularly beneficial in high-performance applications or for extending the lifespan of the engine.

Cummins Corporation

Cummins Inc. is a well-established manufacturer in the heavy-duty truck industry, known for its wide range of engine and component products. The company’s reputation is built on a history of innovation, quality, and reliability. Cummins components, including the 3092513, are trusted by professionals for their performance and durability in demanding applications.

Compatibility with QST30 CM552 Engines

The 3092513 is compatible with the QST30 CM552 engines. These engines are known for their robust design and are often used in heavy-duty applications. The lever’s precision engineering ensures smooth operation and longevity, reducing the likelihood of valve train failures.

Application Considerations

When installing the 3092513, it is crucial to ensure that it is properly aligned and torqued to the manufacturer’s specifications. This will help maintain the integrity of the valve train and prevent premature wear or failure. Additionally, regular maintenance and inspection of the lever and associated components can help identify potential issues before they become critical.

Installation and Maintenance

Proper installation of the 3092513 involves careful alignment with the camshaft and pushrods. This ensures that the lever operates smoothly and efficiently, contributing to the overall performance of the engine. Regular maintenance, including checking for wear and ensuring proper lubrication, is essential to prolong the life of the lever and the associated components.

Role of the 3092513 in Engine Systems

The 3092513 is an integral component in the operation of various engine systems. It works in conjunction with several other components to ensure the efficient transfer of motion within the engine.

Interaction with Valve Mechanisms

The 3092513 is primarily responsible for transferring the motion from the camshaft to the valves. This transfer is essential for the opening and closing of the valves at precise moments, which is vital for the intake and exhaust processes. The lever component of the rocker arm amplifies the motion from the camshaft, providing the necessary force to operate the valves effectively.

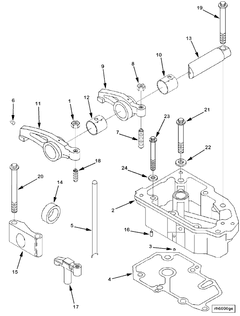

Integration with the Top-Level Assembly

In the context of the rocker (top-level assembly), the 3092513 plays a significant role. This assembly often includes multiple rocker arms and levers, each responsible for a specific valve. The precise alignment and operation of these components are necessary for the synchronized function of the engine’s valve train. The lever ensures that the motion from the camshaft is correctly transmitted to the valve, maintaining the engine’s performance and efficiency.

Coordination with Other Engine Components

The Rocker Arm Lever also interacts with other engine components such as the pushrods in overhead valve (OHV) engines. The pushrods transmit motion from the camshaft to the rocker arms. The 3092513, as part of the rocker arm, receives this motion and converts it into the necessary action on the valve. This coordination is essential for the proper timing and force application required for valve operation.

Ensuring Smooth Operation

The design and function of the 3092513 contribute to the smooth and reliable operation of the engine. By ensuring that the valves open and close at the correct times and with the appropriate force, this component helps maintain the engine’s overall performance. Its role in the valve train mechanism is fundamental to the engine’s ability to deliver power efficiently and consistently.

Conclusion

The 3092513 Rocker Arm Lever is a critical component in the valve train system of Cummins engines, particularly the QST30 CM552 models. Its robust design, precise engineering, and compatibility with specific engine models ensure smooth operation and longevity. Regular maintenance and proper installation are essential to maximize its performance and reliability. Understanding its role and benefits can help professionals maintain and enhance the efficiency of heavy-duty truck engines.

-

Wright, G. (2015). Fundamentals of Medium-Heavy Duty Diesel Engines. Jones & Bartlett Learning.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.