This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

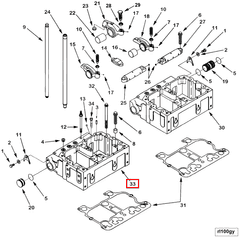

The Rocker Lever Housing, specifically Part #3255730 by Cummins, is integral to the operation of commercial trucks by facilitating the movement of the engine’s valve train. This component ensures efficient valve actuation and contributes to the overall performance of the engine. Cummins, a reputable name in the automotive industry, is known for delivering high-quality components designed to enhance the functionality and reliability of commercial vehicles 1.

Basic Concepts of Rocker Lever Housing

Rocker lever housings are fundamental to the operation of an engine’s valve train. They serve as the mounting point for rocker arms, which transfer motion from the camshaft to the valves. The housing ensures precise alignment and secure attachment of the rocker arms, allowing for efficient valve opening and closing. This interaction is essential for maintaining the engine’s combustion cycle and overall efficiency 3.

Purpose of the 3255730 Rocker Lever Housing

This Cummins part is designed to provide a stable platform for the rocker arms, enabling them to actuate the valves with precision. It ensures that the valves open and close at the correct times, which is vital for maintaining combustion efficiency and power output 1.

Key Features

The 3255730 Rocker Lever Housing is characterized by several key features that enhance its durability and efficiency. It is constructed from high-quality materials that offer resistance to wear and corrosion. The design includes precise machining to ensure a perfect fit within the engine assembly. Additionally, the housing may incorporate features such as integrated lubrication channels to reduce friction and wear on moving parts 2.

Benefits

The advantages of using this part include improved engine performance and reliability. The precise engineering and high-quality materials contribute to the longevity of the component, reducing the need for frequent replacements. Furthermore, the design may offer cost-effectiveness through reduced maintenance requirements and enhanced engine efficiency, leading to potential fuel savings 1.

Troubleshooting and Maintenance

Common issues with the 3255730 Rocker Lever Housing may include wear on the mounting points or damage to the housing itself. Regular inspection and maintenance are recommended to ensure optimal performance. Signs of wear or failure, such as unusual engine noises or decreased performance, should prompt a thorough inspection. Proper maintenance practices, including keeping the housing clean and ensuring adequate lubrication, can help prevent issues and extend the component’s lifespan 1.

Cummins Overview

Cummins Inc. has established a strong reputation in the automotive industry for its commitment to innovation and quality. With a history of developing reliable and efficient engine components, Cummins continues to lead in the design and manufacturing of parts for commercial trucks. The company’s range of products is known for enhancing the performance and durability of vehicles, making Cummins a trusted name among fleet operators and maintenance professionals 1.

Understanding the Integration of Part 3255730 Rocker Lever Housing in Engine Systems

This part is an essential component in the operation of various engine systems, particularly those utilizing overhead valve (OHV) or overhead cam (OHC) designs. This housing serves as the structural backbone for the rocker lever mechanism, ensuring precise and reliable operation of the valve train.

In an OHV engine, the rocker lever housing mounts directly to the cylinder head, providing a stable platform for the rocker arms. These rocker arms are pivotal in transferring the motion from the pushrods, which are actuated by the camshaft lobes, to the valves. The housing must be securely fastened to the head to withstand the dynamic forces exerted during engine operation. It also facilitates the adjustment of valve clearances, a maintenance procedure vital for the longevity and performance of the engine 3.

For OHC engines, the rocker lever housing may be integrated into the cylinder head or exist as a separate component, depending on the engine’s design. In this configuration, the housing supports rocker arms that are directly actuated by the camshaft. This setup allows for a more direct transfer of motion to the valves, potentially enhancing engine efficiency and performance. The housing in OHC systems also plays a role in maintaining the correct geometry and alignment of the rocker arms, which is essential for consistent valve operation 2.

In both OHV and OHC systems, the rocker lever housing is designed to accommodate lubrication from the engine’s oil system. Proper lubrication is necessary to reduce friction and wear on the rocker arms and their pivot points. The housing may feature oil galleries or passages that direct oil to these critical areas, ensuring smooth operation and prolonging the lifespan of the valve train components 2.

The integration of the rocker lever housing with other engine components, such as the cylinder head, camshaft, and valve train, underscores its importance in the overall functionality of the engine. Engineers and mechanics must ensure that the housing is correctly installed and maintained to support the intricate dance of the engine’s moving parts 3.

Conclusion

The 3255730 Rocker Lever Housing by Cummins is a critical component in the operation of commercial truck engines. Its role in facilitating efficient valve actuation and contributing to engine performance cannot be overstated. The precise engineering, high-quality materials, and thoughtful design features of this part ensure durability, reliability, and cost-effectiveness. Regular maintenance and proper installation are essential to maximize the benefits of this component and ensure the longevity of the engine system.

-

Dempsey, Paul. Troubleshooting and Repairing Diesel Engines, 5th Edition. McGraw-Hill, 2018.

↩ ↩ ↩ ↩ ↩ -

Robert Bosch GmbH. Bosch Automotive Handbook 9th Edition. Robert Bosch GmbH, 2014.

↩ ↩ ↩ -

Arora, Shashank, Alireza Tashakori Abkenar, and Shantha Gamini Jayasi. Heavyduty Electric Vehicles: From Concept to Reality. Elsevier, 2021.

↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.