This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 3426183 Rocker Lever Support, manufactured by Cummins, is a critical component in the operation of commercial trucks. Cummins, a renowned name in the engine manufacturing industry, produces a variety of parts designed to enhance the performance and reliability of heavy-duty vehicles. This part plays a significant role in the engine’s valve train system.

Basic Concepts of Rocker Lever Support

A Rocker Lever Support is a mechanical component that facilitates the operation of the valve train in an engine. It acts as a pivot point for the rocker arm, which in turn operates the engine valves. The rocker arm transfers motion from the camshaft to the valves, ensuring they open and close at the correct times. The Rocker Lever Support provides the necessary stability and alignment for this process, interacting closely with the camshaft, rocker arms, and valve components 1.

Purpose of the 3426183 Rocker Lever Support

This Cummins part is designed to enhance the functionality of the valve train system in truck engines. It supports the rocker arms, allowing them to efficiently transfer motion from the camshaft to the valves. This ensures precise valve timing, which is essential for optimal engine performance. By providing a stable mounting point, the 3426183 Rocker Lever Support contributes to the overall efficiency and reliability of the engine.

Key Features

The 3426183 Rocker Lever Support boasts several key features that enhance its performance and durability. It is constructed from high-quality materials, ensuring it can withstand the rigors of heavy-duty truck operation. The design includes precise machining to ensure accurate alignment and minimal wear. Additionally, the support may feature unique characteristics such as integrated lubrication channels to reduce friction and enhance longevity.

Benefits

This part offers several benefits that contribute to improved engine performance. Its robust construction and precise design help maintain optimal valve timing, leading to enhanced engine efficiency. The durability of the support ensures long-term reliability, reducing the need for frequent replacements. Additionally, the component’s design may include features that facilitate easier maintenance and inspection, further contributing to the engine’s overall performance and longevity.

Installation Process

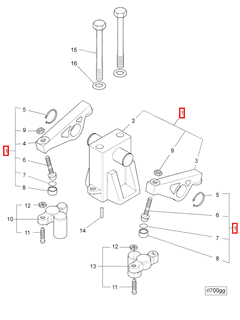

Installing the 3426183 Rocker Lever Support involves several steps to ensure proper integration into the engine. Begin by preparing the engine block, ensuring the mounting surface is clean and free of debris. Position the support in its designated location and secure it using the appropriate fasteners. It is important to torque the fasteners to the manufacturer’s specified values to ensure a secure fit. Finally, verify the alignment of the rocker arms and ensure there is no excessive play or misalignment.

Troubleshooting

Common issues associated with the 3426183 Rocker Lever Support may include misalignment, wear, or damage. Symptoms to look out for include unusual engine noise, decreased performance, or irregular valve operation. To troubleshoot, inspect the support for signs of wear or damage. Ensure the fasteners are tightened to the correct specifications and that the rocker arms are properly aligned. If issues persist, it may be necessary to replace the support or consult a professional for further diagnosis.

Maintenance Tips

To ensure the optimal performance and longevity of the 3426183 Rocker Lever Support, regular maintenance is recommended. Inspect the support during routine engine checks for signs of wear or damage. Clean the component as necessary to remove any buildup that could affect its operation. Additionally, ensure that the fasteners remain tightened to the manufacturer’s specifications. Following these maintenance tips will help maintain the efficiency and reliability of the engine’s valve train system.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. Founded in 1919, Cummins has a long-standing reputation for producing high-quality, reliable components for a variety of industries, including commercial trucking. The company’s extensive product range and commitment to innovation have established it as a trusted name in the engine manufacturing industry.

Rocker Lever Support (Part 3426183) Compatibility with Cummins Engines

This part, manufactured by Cummins, is designed to be compatible with a range of Cummins engines. It is integral to the proper functioning of the engine’s valve train system, ensuring that the rocker levers are securely supported and properly aligned.

Compatibility with Specific Engine Models

-

QSV81G and QSV91G Engines The 3426183 is engineered to fit seamlessly with the QSV81G and QSV91G engines. These engines are known for their robust performance and reliability, making the support part crucial for maintaining the integrity of the valve train system.

-

QSW/QSV82 Engines For the QSW/QSV82 engines, the 3426183 is also a perfect match. This engine model benefits from the precise fit and durability of the support part, ensuring smooth operation and longevity of the engine components.

-

QSW27 and QSW36 Engines The 3426183 is compatible with both the QSW27 and QSW36 engines. These engines, while differing in some specifications, share a common need for reliable valve train support, which this part provides effectively.

-

QSW73 Engine The QSW73 engine also utilizes the 3426183. This part’s design ensures that the rocker levers are adequately supported, contributing to the overall efficiency and performance of the engine.

Grouping of Compatible Engines

The compatibility of the 3426183 with the listed engines can be grouped based on their shared characteristics and design requirements. The QSV81G, QSV91G, and QSW/QSV82 engines, being part of the QSV series, share similar valve train configurations, making the support part a universal fit. Similarly, the QSW27 and QSW36 engines, while distinct, also benefit from the same support part due to their shared engineering principles. The QSW73 engine, though different, also aligns with the design specifications of the 3426183.

Role of Part 3426183 Rocker Lever Support in Engine Systems

In the intricate dance of engine components, the 3426183 plays a significant role in ensuring the smooth operation of the valve train system. This component is designed to provide a stable mounting point for the rocker lever, which is a pivotal part of the valve actuation mechanism.

The rocker lever, often part of a larger rocker assembly, is responsible for transferring motion from the camshaft to the valves. It amplifies the camshaft’s motion, allowing for precise control over the opening and closing of the engine’s valves. The rocker lever support ensures that this transfer of motion is consistent and reliable by securely holding the rocker lever in place.

When considering the lever assembly, which includes the rocker and its associated components, the rocker lever support is essential for maintaining the correct geometry and alignment. This is particularly important in high-performance engines where even minor deviations can lead to significant changes in engine performance and efficiency.

Furthermore, the rocker assembly lever system relies on the stability provided by the rocker lever support to maintain the integrity of the valve timing. This is vital for the engine’s overall performance, as it ensures that the valves open and close at the precise moments required for optimal combustion.

Conclusion

In summary, the 3426183 is a key component in the valve train system, providing the necessary stability and alignment for the rocker lever and associated assemblies to function effectively. Its role in maintaining the precision and reliability of valve actuation cannot be overstated.

-

Ferrari, A., & Pizzo, P. (2022). Injection Technologies: Mixture Formation Strategies. SAE International.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.