This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

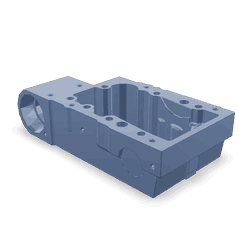

The Rocker Lever Housing 3650897, a component manufactured by Cummins, is integral to the functionality of truck engines, particularly in the valve train system. Cummins, a prominent name in the automotive industry, is renowned for its heavy-duty truck engines. This housing ensures the efficient operation of the valve train system by providing a secure mounting point for the rocker arms.

Basic Concepts of Rocker Lever Housing

A Rocker Lever Housing is a critical part of the engine’s valve train system. It serves as a mounting point for the rocker arms, which are essential for the operation of the engine’s valves. The housing interacts with the cylinder head, rocker arms, and pushrods to facilitate the synchronized opening and closing of the engine’s valves with the piston’s movement 1.

Purpose of Rocker Lever Housing 3650897

This Cummins part is designed to enhance the operation of the valve train in Cummins engines. It ensures precise alignment and secure mounting of the rocker arms, which transfer motion from the pushrods to the valves. This contributes to the efficient and reliable operation of the engine by maintaining the integrity of the valve train system 2.

Key Features

The 3650897 is constructed from high-quality materials, ensuring durability and resistance to wear. Its design includes specific mounting points and alignment features for correct positioning of the rocker arms. Additionally, the housing may incorporate features that reduce noise and vibration, contributing to smoother engine operation 3.

Benefits

Using the 3650897 offers several advantages. It contributes to improved engine efficiency by ensuring the valve train operates smoothly and reliably. The durable construction enhances the engine’s longevity, while its precise design helps maintain optimal engine performance over time 4.

Installation Process

Installing the 3650897 requires careful attention to detail. The process involves securing the housing to the cylinder head, ensuring proper alignment with the valve train system components. Following the manufacturer’s guidelines is vital for correct and secure installation, which is crucial for the engine’s performance and longevity.

Common Issues and Troubleshooting

Typical problems with Rocker Lever Housings can include misalignment, wear, or damage to the housing or its mounting points. Diagnosing these issues involves a thorough inspection of the valve train system. Solutions may range from realigning or tightening components to replacing damaged parts, depending on the severity of the issue.

Maintenance Tips

Routine maintenance of the 3650897 is important for its longevity and optimal performance. This includes regular inspections for signs of wear or damage, ensuring all mounting points are secure, and addressing any issues promptly. Additionally, keeping the engine clean and well-lubricated can help prevent problems related to the valve train system.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, related technologies, and services. With a history spanning over a century, Cummins is renowned for its innovation, quality, and reliability in the automotive industry. The company’s product range includes engines for on-highway and off-highway applications, as well as power generation and filtration systems. Cummins’ reputation for excellence is built on its commitment to customer satisfaction, technological advancement, and sustainable practices.

Compatibility with Cummins Engines

The 3650897 is designed to fit seamlessly with a range of Cummins engines. It is integral to the engine’s valve train system, ensuring smooth and reliable operation.

QSK60 CM500 and QSK60 CM850 MCRS

This part is compatible with both the QSK60 CM500 and the QSK60 CM850 MCRS engines. These engines are part of Cummins’ QSK60 series, known for their robust performance and reliability in various applications. The housing ensures that the rocker levers operate smoothly, maintaining the precise valve timing necessary for optimal engine performance.

QSK60 G CM2358 K110

The 3650897 also fits the QSK60 G CM2358 K110 engine. This engine variant is designed for specific applications requiring high power output and durability. The housing is engineered to withstand the rigors of these demanding conditions, ensuring longevity and consistent performance.

QSK60G

Finally, the 3650897 is also suitable for the QSK60G engine. This engine is part of Cummins’ lineup of high-performance diesel engines, often used in heavy-duty applications. The housing is critical in maintaining the engine’s efficiency and reliability, providing a stable platform for the rocker levers to operate.

Role in Engine Systems

The 3650897 is an integral component in the operation of engine systems, particularly in the valve train mechanism. This housing encases and supports the rocker lever, which is a pivotal element in the transfer of motion from the camshaft to the valves.

Interaction with the Rocker Lever

The rocker lever, mounted within the 3650897, operates on the principle of leverage to amplify the motion imparted by the camshaft. As the camshaft lobe rises, it pushes against one end of the rocker lever, causing the opposite end to depress. This action opens the valve, allowing air and fuel into the combustion chamber or expelling exhaust gases.

Support and Stability

The 3650897 provides a stable mounting point for the rocker lever, ensuring that it remains securely in place during engine operation. This stability is essential for maintaining the precise alignment and operation of the valve train components.

Integration with Other Components

-

Camshaft: The camshaft’s lobes interact directly with the rocker lever housed within the 3650897 component. This interaction is fundamental to the timing and efficiency of valve operation.

-

Valves: The ultimate recipients of the motion transferred by the rocker lever. The efficiency of this transfer, influenced by the stability provided by the 3650897 housing, directly impacts engine performance.

-

Pushrods (in pushrod engine configurations): In engines that utilize pushrods, these components transmit motion from the camshaft to the rocker lever. The 3650897 housing ensures that the rocker lever is correctly positioned to receive this motion.

-

Springs and Retainers: These components work in conjunction with the valves and are indirectly influenced by the operation of the rocker lever and its housing. The stability and precision offered by the 3650897 housing contribute to the overall reliability of valve operation.

Conclusion

In summary, the 3650897 plays a significant role in the efficient and reliable operation of the valve train in engine systems. Its design and function are tailored to support and enhance the performance of the rocker lever and, by extension, the entire valve train mechanism.

-

Nunney, MJ. Light and Heavy Vehicle Technology, Fourth Edition. Butterworth-Heinemann, 2007.

↩ -

Denton, Tom and Pells, Hayley. Automotive Technician Training Theory. Routledge, 2022.

↩ -

Kasab, John and Strzelec, Andrea. Automotive Emissions Regulations and Exhaust Aftertreatment Systems. SAE International, 2020.

↩ -

Atkins, Richard D. An Introduction to Engine Testing and Development. SAE International, 2009.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.