This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

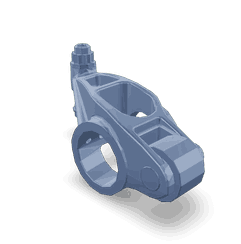

The Cummins 3695366 Rocker Lever is a component designed for use in commercial truck engines. It serves a specific function within the engine’s valve train, contributing to the overall performance and reliability of the engine. Understanding its purpose and significance is important for maintaining and optimizing the operation of commercial trucks.

Basic Concepts of Rocker Levers

A rocker lever, also known as a rocker arm, is a pivotal component in an engine’s valve train mechanism. It acts as a lever that converts the motion from the camshaft into the vertical motion needed to open and close the engine’s valves. This conversion allows for precise timing and control of the valve operation, which is crucial for the engine’s combustion process 1.

Purpose of the 3695366 Rocker Lever

The 3695366 Rocker Lever plays a role in the operation of a truck engine by transferring motion from the camshaft to the valves. It interacts with the camshaft through a cam lobe and, in turn, actuates the valves to open and close at specific intervals. This interaction ensures that the air-fuel mixture enters the combustion chamber at the correct time and that exhaust gases are expelled efficiently 2.

Key Features

The 3695366 Rocker Lever is constructed from high-quality materials that provide durability and resistance to wear. Its design includes features such as a hardened contact surface for the cam lobe and precise geometry to ensure smooth operation. These characteristics contribute to the lever’s performance and longevity under the demanding conditions of commercial truck engines 3.

Benefits

The use of the 3695366 Rocker Lever in an engine can lead to improved efficiency, as it allows for more precise valve timing and operation. Its robust construction enhances the durability of the valve train, and its reliable performance under heavy-duty conditions supports the overall reliability of the engine 4.

Installation Process

Installing the 3695366 Rocker Lever requires careful attention to detail. The process involves positioning the lever over the valve stem, ensuring proper alignment with the camshaft, and securing it in place. Tools such as torque wrenches may be necessary to achieve the correct tension. Alignment checks should be performed to confirm that the lever operates within the specified tolerances 5.

Troubleshooting Common Issues

Common issues with rocker levers may include noise, wear, or malfunction. These can often be traced to improper installation, lack of lubrication, or material fatigue. Troubleshooting steps may involve inspecting the lever for signs of wear, checking the alignment and tension, and ensuring that lubrication is adequate. Addressing these issues promptly can prevent more significant engine problems 6.

Maintenance Tips

Regular maintenance of the 3695366 Rocker Lever is important for prolonging its life and ensuring optimal engine performance. This includes periodic inspections for wear or damage, adhering to lubrication guidelines to reduce friction and wear, and replacing the lever if it shows signs of excessive wear or failure 7.

Compatibility

The 3695366 Rocker Lever is designed to fit a variety of engine models. This component is integral to the engine’s valve train system, ensuring proper valve operation and engine performance. Below is a detailed breakdown of the engines with which this rocker lever is compatible:

Compatible Engines

- ISG11 CM2880 G108

- ISG12 CM2880 G107

- ISG12 G CMOH6.0 G111

- QSG12 CM2880 G112

- QSG12/X12 CM2350 G110

- X11 CM2670 X126B

- X12 CM2350 X119B

- X12 CM2670 X121B

- X13 CM2670 X122B

These engines share a similar architecture in their valve train systems, allowing the 3695366 rocker lever to be a direct fit. The commonality in design ensures that the rocker lever can perform its function effectively across these models.

Integration in Engine Systems

The 3695366 Rocker Lever is an essential component in the operation of various engine systems, particularly in the actuation of valves within the cylinder head. This component works in conjunction with several other parts to ensure the smooth and efficient functioning of the engine.

Interaction with the Cylinder Head

The cylinder head is a key part of the engine, housing the combustion chamber and valves. The rocker lever, specifically part 3695366, plays a significant role in this setup by transferring motion from the camshaft to the valves. This transfer is vital for the opening and closing of the valves at precise moments, which is necessary for the intake of air-fuel mixture and the exhaust of combustion gases 8.

Coordination with the Lever and Rocker

In the valve train mechanism, the lever and rocker components are interconnected. The rocker lever, identified as part 3695366, is typically mounted on a pivot point and is actuated by the camshaft. As the camshaft rotates, it pushes against the rocker lever, which then amplifies this motion to open the valve. The lever, often a part of the rocker assembly, ensures that the force is transmitted efficiently to achieve the required valve lift 9.

Overall Functionality in the Valve Train

The integration of part 3695366 within the valve train is designed to enhance engine performance by ensuring that valves operate with the correct timing and force. This component’s role in amplifying the camshaft’s motion allows for greater precision in valve operation, which is essential for maintaining engine efficiency and power output. The rocker lever’s design and material are optimized to withstand the high stresses and temperatures within the engine compartment, ensuring reliable operation over the engine’s lifespan 10.

Conclusion

The Cummins 3695366 Rocker Lever is a critical component in the valve train of commercial truck engines, ensuring precise valve timing and operation. Its robust construction and compatibility with various engine models make it a reliable choice for maintaining engine performance and reliability. Regular maintenance and proper installation are key to maximizing the lifespan and efficiency of this Cummins part.

-

Van Gelder, K. T. (2018). Fundamentals of Automotive Technology Principles and Practice. Jones Bartlett Learning.

↩ -

Brach, R. M. (2023). SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety. SAE Books.

↩ -

Heywood, J. (2019). Internal Combustion Engine Fundamentals. McGraw-Hill Education.

↩ -

Hilgers, M. (2022). The Drivers Cab. Springer Vieweg.

↩ -

Cummins Inc. (n.d.). QSB6.7 CM2250 B128, Service Manual (4388601).

↩ -

Cummins Inc. (n.d.). QSB6.7 CM2250 B128, Service Manual (4388601).

↩ -

Cummins Inc. (n.d.). QSB6.7 CM2250 B128, Service Manual (4388601).

↩ -

Cummins Inc. (n.d.). QSB6.7 CM2250 B128, Service Manual (4388601).

↩ -

Cummins Inc. (n.d.). QSB6.7 CM2250 B128, Service Manual (4388601).

↩ -

Cummins Inc. (n.d.). QSB6.7 CM2250 B128, Service Manual (4388601).

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.