This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

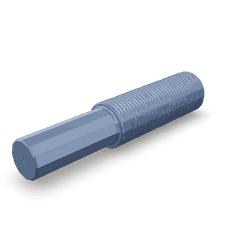

The Rocker Lever Adjusting Screw, identified by Part #3695990, is a component manufactured by Cummins, a renowned name in the automotive and heavy-duty truck industry. This screw plays a significant role in the operation of an engine, particularly within the valve train system. Its design and functionality are tailored to ensure the efficient and reliable performance of commercial trucks.

Basic Concepts and Functionality

The Rocker Lever Adjusting Screw is integral to the valve train system, where it operates to maintain the proper clearance between the valve and the camshaft. This clearance is vital for the precise operation of the valve, ensuring it opens and closes at the correct times in the engine cycle. The screw interacts with the rocker arm, allowing for adjustments that compensate for wear and thermal expansion, thus maintaining optimal valve operation throughout the engine’s lifespan 1.

Purpose and Role in Truck Operation

In the context of truck operation, the Rocker Lever Adjusting Screw serves to ensure that the valves operate within their specified parameters. This is crucial for the engine’s efficiency and performance, as it directly affects the combustion process. By maintaining the correct valve clearance, the screw contributes to the engine’s ability to deliver power consistently and efficiently, which is particularly important in the demanding conditions faced by commercial trucks 2.

Key Features

The design of the Rocker Lever Adjusting Screw incorporates several features that enhance its functionality and durability. It is typically made from high-strength materials to withstand the high stresses and temperatures within the engine environment. The screw’s design allows for easy adjustment, which is a critical aspect of its maintenance. Additionally, its construction may include features that prevent it from loosening under vibration, ensuring that the valve clearance remains consistent over time 3.

Benefits

The Rocker Lever Adjusting Screw offers several advantages that contribute to engine performance and reliability. By ensuring proper valve clearance, it helps to optimize the combustion process, leading to improved engine efficiency. Additionally, its design reduces the need for frequent adjustments, lowering maintenance requirements. The durability of the screw also enhances the overall reliability of the engine, making it a valuable component in heavy-duty applications.

Troubleshooting and Maintenance

Identifying issues with the Rocker Lever Adjusting Screw can involve checking for symptoms such as engine misfires, reduced performance, or unusual noises from the valve train. Regular maintenance practices, including periodic checks of the valve clearance and the condition of the screw, are recommended to ensure its proper function. If adjustment or replacement is necessary, following the manufacturer’s guidelines is important to maintain engine performance and longevity.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for producing high-quality engine components that are trusted by industries worldwide. Their commitment to innovation, quality, and customer satisfaction underscores their position as a leader in the automotive and heavy-duty truck sectors.

Compatibility of Rocker Lever Adjusting Screw (Part 3695990) with Cummins Engines

The Rocker Lever Adjusting Screw (Part 3695990) by Cummins is designed to fit a variety of engine models, ensuring precise adjustments for optimal engine performance. Here’s a detailed look at its compatibility with the listed engines:

ISG11 CM2880 G108 and ISG12 CM2880 G107

Both the ISG11 CM2880 G108 and ISG12 CM2880 G107 engines are part of the same family, sharing similar design principles and components. The Rocker Lever Adjusting Screw is compatible with these engines, facilitating the fine-tuning of rocker arm clearances, which is crucial for maintaining the engine’s operational efficiency and longevity.

ISG12 G CMOH6.0 G111

The ISG12 G CMOH6.0 G111 engine also benefits from the use of the Rocker Lever Adjusting Screw. This part is essential for adjusting the clearance between the rocker levers and the camshaft, ensuring that the engine operates smoothly and efficiently.

QSG12/X12 CM2350 G110

The QSG12/X12 CM2350 G110 engine is another model where the Rocker Lever Adjusting Screw is applicable. This component helps in the precise adjustment of the rocker arm clearance, which is vital for the engine’s performance and reliability.

X11 CM2670 X126B and X12 CM2350 X119B

The X11 CM2670 X126B and X12 CM2350 X119B engines are designed for different applications but share the need for precise valve train adjustments. The Rocker Lever Adjusting Screw is compatible with both, ensuring that the rocker arms are correctly set to prevent any potential engine issues.

X12 CM2670 X121B and X12N CMMDG1 X143B

The X12 CM2670 X121B and X12N CMMDG1 X143B engines also require the Rocker Lever Adjusting Screw for maintaining the correct clearance between the rocker arms and the camshaft. This ensures that the engine runs smoothly and efficiently.

X13 CM2670 X122B

Finally, the X13 CM2670 X122B engine is another model that benefits from the Rocker Lever Adjusting Screw. This part is essential for ensuring that the rocker arms are correctly adjusted, which is crucial for the engine’s performance and longevity.

Conclusion

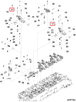

The 3695990 Rocker Lever Adjusting Screw is a critical component in the precise operation of several engine systems. It is specifically designed to work in conjunction with the cylinder head and the cylinder top-level assembly head, ensuring optimal performance and efficiency. When installed, the adjusting screw interacts directly with the rocker lever and the rocker top-level assembly lever. This interaction is fundamental in maintaining the correct valve clearance, which is vital for the engine’s combustion process. The screw allows for fine-tuning of the rocker lever’s position, which in turn affects how the valves open and close. This adjustment is necessary to compensate for wear and tear over time, ensuring that the valves operate within the manufacturer’s specified tolerances.

The cylinder head, a complex component housing the combustion chamber, relies on the precise operation of the valves to function correctly. The cylinder top-level assembly head, which includes various passages and ports for coolant and oil, also benefits from the stability and accuracy provided by the adjusting screw. This ensures consistent engine performance and longevity.

The rocker lever, a pivotal part of the valve train, uses the adjusting screw to maintain the correct preload on the valve springs. This preload is essential for quick and reliable valve actuation, directly impacting the engine’s power output and fuel efficiency. The rocker top-level assembly lever, which may include additional components like dampers or springs, also depends on the adjusting screw for optimal function.

In summary, the 3695990 Rocker Lever Adjusting Screw plays a significant role in the coordination and efficiency of the cylinder head, cylinder top-level assembly head, rocker lever, and rocker top-level assembly lever. Its proper installation and adjustment are key to ensuring the engine operates smoothly and efficiently.

-

Bennett, S., & Norman, I. A. (2011). Heavy Duty Truck Systems Fifth Edition. Delmar Cengage Learning.

↩ -

Thompson, R. (2019). Automotive Maintenance: Light Repair. Cengage Learning.

↩ -

Dixon, J. (2014). Modern Diesel Technology: Heating, Ventilation, Air Conditioning, Refrigeration, 2nd Edition. Cengage Learning.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.