3910810

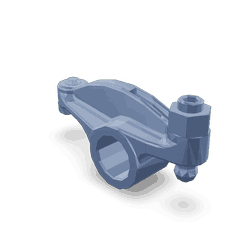

Rocker Lever

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3910810 Rocker Lever is a component designed for use in commercial truck engines. It serves a specific function within the engine’s valve train, contributing to the overall operation and efficiency of the truck. Understanding its purpose and significance is fundamental for maintaining and optimizing truck performance.

Basic Concepts of Rocker Levers

A rocker lever, also known as a rocker arm, is a pivotal component in an engine’s valve train. It operates on the principle of leverage, amplifying the motion from the camshaft to open and close the engine’s valves. This mechanism ensures that the valves open and close at precise times, allowing for the intake of air and fuel and the expulsion of exhaust gases, which are essential processes for engine operation 1.

Role of the 3910810 Rocker Lever in Truck Operation

The 3910810 Rocker Lever plays a role in the operation of a truck engine by transferring motion from the camshaft to the valves. It interacts with the camshaft, pushrods, and valves, ensuring that the valves open and close in sync with the engine’s cycles. This precise timing is vital for the engine’s performance, fuel efficiency, and emissions control.

Key Features of the 3910810 Rocker Lever

The 3910810 Rocker Lever is characterized by several key features that enhance its functionality and durability. It is constructed from high-strength materials to withstand the rigors of commercial truck operation. Its design includes specific geometry and surface treatments that reduce friction and wear, contributing to its longevity and reliable performance.

Benefits of Using the 3910810 Rocker Lever

Incorporating the 3910810 Rocker Lever into a truck engine can lead to improved performance, durability, and reliability. Its precise engineering ensures efficient valve operation, which can enhance engine efficiency and reduce emissions. Additionally, its robust construction contributes to the overall durability and reliability of the engine.

Installation Process

Installing the 3910810 Rocker Lever requires careful attention to detail and the use of appropriate tools. The process involves removing the old rocker lever, inspecting the valve train components for wear or damage, and then installing the new rocker lever. It is important to follow manufacturer guidelines to ensure proper installation and to avoid potential issues.

Troubleshooting Common Issues

Common issues with the 3910810 Rocker Lever may include noise, improper valve timing, or valve train wear. Troubleshooting these issues involves inspecting the rocker lever and related components for signs of wear or damage, ensuring proper installation, and addressing any issues promptly to maintain engine performance.

Maintenance Tips

Regular maintenance of the 3910810 Rocker Lever is key to ensuring its longevity and optimal performance. This includes periodic inspections for wear or damage, ensuring proper lubrication, and addressing any issues as they arise. Adhering to recommended maintenance schedules can help prevent unexpected failures and extend the life of the component.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a rich history in the commercial truck industry, Cummins is renowned for its high-quality, reliable, and efficient products. The company’s extensive product range and commitment to innovation have established it as a trusted name in the industry.

Compatibility of Rocker Lever Part 3910810 with Cummins Engines

The Rocker Lever part 3910810, manufactured by Cummins, is designed to fit a variety of Cummins engines. This part is crucial for the proper functioning of the valve train in these engines, ensuring smooth and efficient operation. Below is a detailed breakdown of the engines with which this rocker lever is compatible:

- 4B3.9

- 6B5.9

- B3.9 G

- B4.5

- B5.9 CM2670 B166C

- B5.9 G

- B5.9 GAS PLUS CM556

- B6.7S

- G5.9

- G5.9 CM558

- ISB3.9 CM2220 B107

- ISB5.9 CM2880 B127

- ISB5.9G CM2180

- QSB3.9 30 CM550

- QSB3.9 CM2880 B138

- QSB5.9 30 CM550

- QSB5.9 CM2880 B139

- QSB5.9 CM550

- QSB5.9G

Role of Part 3910810 Rocker Lever in Engine Systems

In the orchestration of an engine’s operation, the Rocker Lever (Part 3910810) assumes a significant role by facilitating the transfer of motion from the camshaft to the valves. This transfer is essential for the precise timing of valve opening and closing, which is fundamental to the engine’s performance and efficiency.

The Rocker Lever is mounted on the Rocker Lever Support, a stationary component that provides a pivot point for the Rocker Lever’s movement. As the Camshaft rotates, it pushes against the Rocker Lever, which then amplifies this motion and transmits it to the Valves. This mechanism ensures that the valves open and close at the correct times in the engine’s cycle.

In engines with multiple cylinders, there are typically multiple Rocker Levers, each serving its respective valve. These Rocker Levers are often grouped together on a Rocker Lever Support, forming a Rocker Lever System that works in unison to manage the valve operations across the engine.

The efficiency of the Rocker Lever system is influenced by the design and material of the Rocker Levers. High-performance engines may utilize lighter and more rigid materials for the Rocker Levers to reduce inertia and improve response times.

Conclusion

In summary, the Rocker Lever (Part 3910810) is a pivotal component in the valve train of an engine, ensuring that the valves operate in harmony with the engine’s rhythm, thereby contributing to the overall performance and longevity of the engine. Regular maintenance and proper installation are essential to maximize the benefits of this Cummins part.

-

Han, Z. (2022). Simulation and Optimization of Internal Combustion Engines. SAE International.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.