3941140

Rocker Lever Support

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

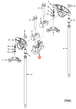

This article provides an overview of the Rocker Lever Support 3941140, a component manufactured by Cummins. It is designed for use in commercial trucks and plays a role in the engine’s valve train system.

Basic Concepts of Rocker Lever Support

A Rocker Lever Support, also known as a rocker arm support or pivot, is a component in an engine’s valve train. It provides a stable mounting point for the rocker arms, which are responsible for transferring motion from the camshaft to the valves. The Rocker Lever Support ensures proper alignment and reduces wear on the rocker arms 1.

Role of 3941140 Rocker Lever Support in Truck Operation

The 3941140 Rocker Lever Support by Cummins is integral to the valve train system of a truck’s engine. It supports the rocker arms, allowing them to efficiently transfer motion from the camshaft to the valves. This ensures that the valves open and close at the correct times, which is vital for the engine’s performance and efficiency 2.

Key Features

- Manufactured by Cummins, a reputable engine manufacturer.

- Designed for durability and reliability in heavy-duty applications.

- Precision-engineered to ensure accurate valve train operation.

- Constructed from high-quality materials to withstand the rigors of commercial truck use.

Benefits

- Enhances the efficiency and performance of the engine’s valve train.

- Contributes to the overall reliability and longevity of the engine.

- Reduces the likelihood of valve train-related issues, leading to lower maintenance costs.

- Ensures consistent and precise valve operation, which is critical for engine performance.

Troubleshooting and Maintenance

Regular inspection of the Rocker Lever Support is recommended to identify any signs of wear or damage. Common issues may include worn pivot points or cracks in the support structure. If any damage is detected, it is advisable to replace the Rocker Lever Support to prevent potential engine problems. Additionally, ensuring that the rocker arms are properly lubricated can help extend the life of the Rocker Lever Support and the entire valve train system 3.

Compatibility with Cummins Engines

The Rocker Lever Support part 3941140 by Cummins is designed to fit a variety of Cummins engines, ensuring stability and proper function of the rocker levers. This part is integral to the engine’s valve train system, providing support and alignment for the rocker levers, which are crucial for the operation of the engine’s valves.

ISC Series Engines

The Rocker Lever Support part 3941140 is compatible with several ISC series engines, including:

- ISC CM2150

- ISC CM554

- ISC CM850

- ISC8.3 CM2250

ISL Series Engines

The part also fits a range of ISL series engines, such as:

- ISL CM2150

- ISL CM554

- ISL G CM2180

- ISL9 CM2150 SN

- ISL9 CM2250

- ISL9.5 CM2880 L138

L Series Engines

The Rocker Lever Support is also suitable for several L series engines, including:

- L GAS PLUS CM556

- L8.9

- L8.9 CM2670 L134C

- L8.9 L121

- L8.9G CMOH2.0 L125B

- L9 CM2670 L128B

- L9.5 L117

QSC Series Engines

The part is also compatible with the following QSC series engines:

- QSC8.3 CM2880 C102

- QSC8.3 CM554

- QSC8.3 CM850 (CM2850)

G Series Engines

Finally, the Rocker Lever Support fits the following G series engines:

- G8.3

- G8.3 CM558

- GTA8.3 CM558

Conclusion

By ensuring the Rocker Lever Support is correctly installed, engine performance and longevity can be maintained, providing a stable and efficient operation across these various engine models. The part 3941140 Rocker Lever Support plays a significant role in the functionality of the rocker lever and rocker lever assembly. Its design and placement are carefully considered to enhance the reliability and performance of the engine’s valvetrain system.

-

Lakshminarayanan, P A, and Yogesh V Aghav. Modelling Diesel Combustion. Springer Science, 2010.

↩ -

Hick, Hannes, Klaus Kupper, and Helfried Sorger. Systems Engineering for Automotive Powertrain Development. Springer, 2021.

↩ -

Mom, Gijs. The Evolution of Automotive Engineering: A Handbook. SAE International, 2023.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.