This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The 3941559 Rocker Lever Support, manufactured by Cummins, is a critical component in the valve train system of heavy-duty truck engines. This part provides a stable platform for the rocker arms, which are essential for actuating the valves and ensuring precise control over the engine’s intake and exhaust processes 1.

Basic Concepts of Rocker Lever Support

A rocker lever support serves as the mounting point for the rocker arms within an engine’s valve train. It facilitates the transfer of motion from the camshaft to the valves, which is fundamental to the engine’s operation. The mechanical principle behind its operation involves leveraging the camshaft’s rotational motion to achieve linear motion in the valves 2.

Purpose of the 3941559 Rocker Lever Support

The 3941559 Rocker Lever Support is designed to enhance the operation of a truck engine’s valve train. It provides a stable and durable mounting point for the rocker arms, contributing to the efficiency and performance of the valve actuation process. This part ensures that the rocker arms can operate with minimal deflection under high stresses and dynamic loads, thereby supporting consistent valve timing and engine performance 3.

Key Features

This Cummins part is engineered with specific design and construction features to meet the demanding requirements of heavy-duty truck engines. It is constructed from high-strength materials to withstand the rigors of engine operation. The engineering specifications of this part include precise tolerances to ensure a proper fit within the engine assembly. Unique attributes such as its robust design and material selection enhance its functionality and durability, making it a reliable component in the valve train system 4.

Benefits

Utilizing the 3941559 Rocker Lever Support in truck engines offers several advantages. These include improved engine performance due to more efficient valve actuation, enhanced durability under high-stress conditions, and increased reliability of the valve train system. These benefits contribute to the overall operation of the truck by ensuring that the engine operates smoothly and efficiently.

Installation Process

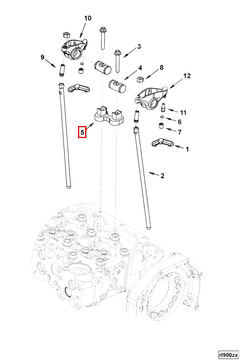

Installing the 3941559 Rocker Lever Support requires careful attention to detail to ensure proper fit and function within the engine assembly. The process involves securing the support in its designated location within the engine block, ensuring that it is aligned correctly with the rocker arms and camshaft. Special tools may be required to achieve the necessary precision during installation. It is important to follow the manufacturer’s guidelines to ensure that the part is installed correctly and functions as intended.

Troubleshooting and Maintenance

Common issues associated with rocker lever supports can include wear, misalignment, or damage due to high operational stresses. Symptoms of these issues may manifest as engine performance problems, such as misfires or reduced efficiency. Diagnostic procedures involve inspecting the support and its interaction with the rocker arms and camshaft for signs of wear or damage. Regular maintenance practices, such as checking for proper alignment and condition, can help ensure the longevity and optimal performance of the 3941559 Rocker Lever Support.

Cummins: Manufacturer Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the automotive industry. The company’s commitment to excellence is evident in its wide range of products, including engine components like the 3941559 Rocker Lever Support, which are designed to meet the high standards of performance and durability required by heavy-duty applications.

Compatibility

The 3941559 Rocker Lever Support is designed to fit seamlessly with a range of Cummins engines, ensuring stability and efficiency in various applications. This part is compatible with the ISB CM550, ISB CM850, and ISBE CM800 engines, providing a reliable support structure for the rocker levers.

For the QSB5.9 series, the 3941559 Rocker Lever Support is engineered to fit both the QSB5.9 44 CM550 and QSB5.9 CM850 engines. This ensures that the rocker levers are properly supported, contributing to the engine’s overall performance and longevity.

In the QSB6.7 series, the 3941559 Rocker Lever Support is specifically designed for the QSB6.7 CM850 (CM2850) engine. This part plays a role in maintaining the integrity of the engine’s valve train, ensuring smooth operation and reducing wear and tear.

Role of Part 3941559 Rocker Lever Support in Engine Systems

The 3941559 Rocker Lever Support is an integral component in the operation of the rocker lever and rocker lever assembly within engine systems. This support ensures the stability and precise movement of the rocker lever, which is essential for the efficient transfer of motion from the camshaft to the valves.

In the rocker lever assembly, the Rocker Lever Support acts as a mounting point, securing the rocker lever in place. This allows the rocker lever to pivot smoothly as the camshaft lobes push against it. The consistent and accurate movement of the rocker lever is vital for the proper opening and closing of the engine’s valves, which directly impacts the engine’s performance and efficiency.

Additionally, the Rocker Lever Support helps in maintaining the alignment of the rocker lever, ensuring that the force applied by the camshaft is transmitted effectively to the valves. This alignment is key to preventing undue stress on the valvetrain components and ensuring the longevity of the engine.

Conclusion

In summary, the 3941559 Rocker Lever Support plays a significant role in the functionality of the rocker lever and rocker lever assembly, contributing to the overall performance and reliability of the engine system.

-

Lakshminarayanan, P. A., & Nayak, N. S. (2011). Critical Component Wear in Heavy Duty Engines. John Wiley & Sons.

↩ -

Bennett, S. (2012). Modern Diesel Technology: Light Duty Diesels. Cengage Learning.

↩ -

Reif, K. (2015). Gasoline Engine Management Systems and Components. Springer Vieweg.

↩ -

Schneider, W.-H. (2016). Pistons and Engine Testing. Springer Nature.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.