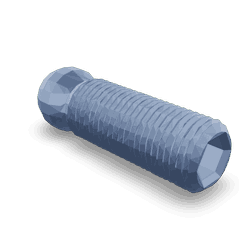

3964720

Rocker Lever Adjusting Screw

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Rocker Lever Adjusting Screw, identified by Part #3964720, is a component manufactured by Cummins, a well-established name in the automotive industry. This screw plays a role in the operation of heavy-duty truck engines, particularly within the valve train system. Its design and function are tailored to meet the demanding requirements of commercial and industrial applications, ensuring reliable performance and durability.

Function and Operation

The Rocker Lever Adjusting Screw operates within the valve train system, where it plays a role in maintaining proper valve clearance. This clearance is vital for the efficient opening and closing of engine valves, which directly impacts engine performance. By allowing for precise adjustments, the screw ensures that the valves operate within optimal parameters, contributing to smooth engine operation and efficiency 1.

Key Features

The Rocker Lever Adjusting Screw is characterized by its precision machining and durable construction. Made from high-quality materials, it is designed to withstand the harsh conditions typical of heavy-duty truck engines. Its compatibility with Cummins engines ensures that it integrates seamlessly into the valve train system, providing reliable performance. The screw’s design allows for easy adjustments, facilitating maintenance and ensuring that the engine operates efficiently over time 2.

Benefits

The use of the Rocker Lever Adjusting Screw offers several advantages. It contributes to enhanced engine efficiency by ensuring that valve clearances are maintained within optimal ranges. This precision reduces the likelihood of valve-related issues, leading to reduced maintenance requirements. Additionally, the durable construction of the screw promotes prolonged component lifespan, offering value to fleet operators and maintenance professionals 3.

Installation and Adjustment

Proper installation and adjustment of the Rocker Lever Adjusting Screw are crucial for achieving optimal valve clearance. The process involves following specific torque specifications and recommended practices to ensure that the screw is securely in place and correctly adjusted. Detailed guidelines are available to assist in this process, emphasizing the importance of precision and adherence to manufacturer recommendations.

Troubleshooting and Maintenance

Common issues associated with the Rocker Lever Adjusting Screw can often be traced to improper installation, adjustment, or wear over time. Diagnostic techniques, such as checking for proper valve clearance and inspecting the screw for signs of wear, can help identify problems early. Regular maintenance practices, including periodic checks and adjustments, are recommended to ensure reliable operation and longevity of the component.

Compatibility and Applications

The Rocker Lever Adjusting Screw is designed for use with various Cummins engine models, making it a versatile component in the heavy-duty truck industry. Its applications span different truck configurations, providing a reliable solution for maintaining valve clearance across a range of operating conditions.

Manufacturer - Cummins

Cummins Inc. is a leading manufacturer in the automotive industry, known for its high-quality engine components and systems. With a rich history and a strong reputation for innovation and reliability, Cummins is committed to producing components that meet the rigorous demands of commercial and industrial applications. The company’s dedication to quality and performance is evident in its product line, including the Rocker Lever Adjusting Screw.

Compatibility of 3964720 with Cummins Engines

This Cummins part is designed to fit a variety of Cummins engines. This component is essential for maintaining proper valve clearance and ensuring optimal engine performance. Below is a detailed breakdown of the engines that are compatible with this part:

ISC Series Engines

- ISC CM2150

- ISC CM554

- ISC CM850

- ISC8.3 CM2250

The ISC series engines, including the CM2150, CM554, CM850, and 8.3 CM2250 variants, are designed for a range of applications, from light-duty to medium-duty trucks. The Rocker Lever Adjusting Screw 3964720 is compatible with these engines, ensuring precise valve adjustments.

ISL Series Engines

- ISL CM2150

- ISL CM554

- ISL G CM2180

- ISL9 CM2150 SN

- ISL9 CM2250

- ISL9.5 CM2880 L138

The ISL series engines, such as the CM2150, CM554, G CM2180, 9 CM2150 SN, 9 CM2250, and 9.5 CM2880 L138 variants, are known for their robust performance and reliability. The Rocker Lever Adjusting Screw 3964720 is suitable for these engines, providing the necessary adjustments for maintaining valve clearance.

L Series Engines

- L GAS PLUS CM556

- L8.9

- L8.9 CM2670 L134C

- L8.9 L121

- L8.9G CMOH2.0 L125B

- L9 CM2670 L128B

- L9.5 L117

The L series engines, including the GAS PLUS CM556, 8.9, 8.9 CM2670 L134C, 8.9 L121, 8.9G CMOH2.0 L125B, 9 CM2670 L128B, and 9.5 L117 variants, are designed for various applications. The Rocker Lever Adjusting Screw 3964720 fits these engines, ensuring that the valve clearance is maintained correctly.

QSC Series Engines

- QSC8.3 CM2880 C102

- QSC8.3 CM554

- QSC8.3 CM850 (CM2850)

The QSC series engines, such as the 8.3 CM2880 C102, 8.3 CM554, and 8.3 CM850 (CM2850) variants, are engineered for high performance and efficiency. The Rocker Lever Adjusting Screw 3964720 is compatible with these engines, providing the necessary adjustments for optimal valve clearance.

This comprehensive compatibility ensures that the Rocker Lever Adjusting Screw 3964720 can be used across a wide range of Cummins engines, facilitating proper maintenance and performance.

Role of Part 3964720 Rocker Lever Adjusting Screw in Engine Systems

In the context of engine systems, the Rocker Lever Adjusting Screw (part 3964720) serves a significant function within the rocker lever and rocker lever assembly. This component is integral to the precise operation of the valve train, ensuring optimal performance and efficiency of the engine.

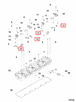

Interaction with the Rocker Lever

The rocker lever is a pivotal element in the valve train mechanism, responsible for transferring motion from the camshaft to the valves. The Rocker Lever Adjusting Screw (part 3964720) plays a key role in fine-tuning the clearance between the rocker lever and the valve stem. This adjustment is essential for maintaining the correct valve timing and ensuring that the valves open and close at the precise moments required for efficient combustion.

Integration within the Rocker Lever Assembly

The rocker lever assembly comprises several components, including the rocker lever, pushrods, and the adjusting screw. The Rocker Lever Adjusting Screw (part 3964720) is positioned within this assembly to allow for micro-adjustments. These adjustments are necessary to compensate for wear and tear over time, ensuring that the valve train operates smoothly and without excessive noise or play.

By enabling these fine-tuned adjustments, part 3964720 ensures that the rocker lever assembly functions harmoniously, contributing to the overall reliability and performance of the engine. This component’s role in maintaining the integrity of the valve train underscores its importance in the engine’s operation.

Conclusion

The Rocker Lever Adjusting Screw, part number 3964720, is a critical component in the valve train system of Cummins engines. Its precise function in maintaining valve clearance ensures optimal engine performance and efficiency. The screw’s durable construction and compatibility with various Cummins engine models make it a reliable choice for heavy-duty applications. Proper installation, adjustment, and maintenance of this part are essential for ensuring the longevity and reliability of the engine.

-

Arthur J Caines, Roger F Haycock and John E Hillier, Automotive Lubricants Reference Book, SAE International, 2004.

↩ -

Konrad Reif Ed, Gasoline Engine Management Systems and Components, Springer Vieweg, 2015.

↩ -

P. A. Lakshminarayanan and Nagaraj S. Nayak, Critical Component Wear in Heavy Duty Engines, John Wiley & Sons, 2011.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.