This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3966277 Rocker Lever is a component used in heavy-duty truck engines, manufactured by Cummins Inc. This part is integral to the engine’s valve train system, ensuring efficient operation and performance of the engine. Cummins Inc. is renowned for its high-quality engine components, and the 3966277 Rocker Lever is no exception, designed to meet the demanding requirements of heavy-duty applications 1.

Basic Concepts of Rocker Levers

A rocker lever, also known as a rocker arm, is a pivotal component in internal combustion engines. Its primary function is to transfer motion from the camshaft to the valves, allowing them to open and close at precise intervals. This transfer of motion is achieved through the rocker lever’s pivot point, which amplifies the camshaft’s motion to operate the valves effectively 2.

Purpose of the 3966277 Rocker Lever

The Cummins 3966277 Rocker Lever plays a specific role in the operation of a truck engine. It interacts with the camshaft and valve train to ensure that the engine’s valves open and close at the correct times. This precise timing is crucial for the engine’s combustion process, affecting its efficiency, power output, and overall performance. The rocker lever’s design allows it to withstand the high stresses and temperatures present in heavy-duty truck engines, ensuring reliable operation under demanding conditions 3.

Key Features

The Cummins 3966277 Rocker Lever is characterized by several key features that enhance its performance. It is constructed from high-strength materials, ensuring durability and resistance to wear. The design includes precise machining for accurate valve actuation and a robust pivot point for smooth operation. Additionally, the rocker lever may feature specific coatings or treatments to reduce friction and improve longevity.

Benefits

The advantages provided by the Cummins 3966277 Rocker Lever include improved engine efficiency, durability, and reliability. Its precise design and high-quality materials contribute to consistent valve operation, which is vital for optimal engine performance. The rocker lever’s ability to withstand high stresses and temperatures ensures that it can operate reliably in the demanding environment of a heavy-duty truck engine.

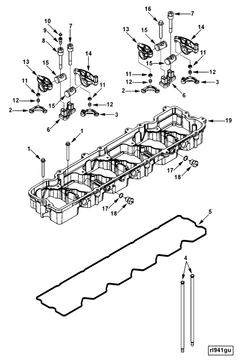

Installation Process

Proper installation of the Cummins 3966277 Rocker Lever involves several steps. First, ensure that the engine is clean and free of debris. The rocker lever should be aligned correctly with the camshaft and valve stem, and any necessary shims should be installed to achieve the correct valve clearance. Tools required may include a torque wrench for tightening bolts and a feeler gauge for measuring valve clearance. Following the manufacturer’s instructions ensures that the rocker lever is installed correctly and functions as intended.

Common Issues and Troubleshooting

Common problems associated with rocker levers can include noise, valve train wear, or improper valve timing. These issues may be caused by incorrect installation, wear and tear, or manufacturing defects. Troubleshooting steps may involve inspecting the rocker lever and related components for signs of wear, ensuring correct installation, and replacing any damaged parts. Regular maintenance and inspection can help prevent these issues.

Maintenance Tips

To ensure the longevity and optimal performance of the Cummins 3966277 Rocker Lever, regular maintenance is recommended. This includes periodic inspection for signs of wear or damage, ensuring proper valve clearance, and cleaning the valve train components to remove any buildup. Following the manufacturer’s maintenance schedule and using high-quality lubricants can contribute to the rocker lever’s reliable operation.

Cummins Inc. Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for innovation, quality, and reliability in the commercial truck industry. The company’s product range includes engines, powertrains, and related components, all designed to meet the needs of heavy-duty applications. Cummins’ commitment to excellence is reflected in its products, including the 3966277 Rocker Lever, which is engineered to deliver performance and durability in demanding environments.

Compatibility of Rocker Lever Part 3966277 with Cummins Engines

The Rocker Lever part 3966277, manufactured by Cummins, is designed to fit a variety of Cummins engines. This part is crucial for the proper functioning of the engine’s valve train, ensuring that the valves operate smoothly and efficiently.

ISC Series Engines

- ISC CM2150

- ISC8.3 CM2250

The Rocker Lever part 3966277 is compatible with the ISC series engines, including the ISC CM2150 and ISC8.3 CM2250. These engines are known for their robust performance and reliability, often used in heavy-duty applications.

ISL Series Engines

- ISL CM2150

- ISL CM554

- ISL9 CM2150 SN

- ISL9 CM2250

- ISL9.5 CM2880 L138

The ISL series engines, such as the ISL CM2150, ISL CM554, ISL9 CM2150 SN, ISL9 CM2250, and ISL9.5 CM2880 L138, also utilize the Rocker Lever part 3966277. These engines are widely used in various industries due to their durability and efficiency.

QSC and QSL Series Engines

- QSC9 CM2250/QSL9 CM2250

- QSL8.9 CM2150 L141

- QSL9 CM2250

- QSL9 CM850 (CM2850)

The QSC and QSL series engines, including the QSC9 CM2250/QSL9 CM2250, QSL8.9 CM2150 L141, QSL9 CM2250, and QSL9 CM850 (CM2850), are also compatible with the Rocker Lever part 3966277. These engines are known for their versatility and are used in a range of applications, from construction to marine.

Each of these engines relies on the Rocker Lever part 3966277 to maintain the precise operation of the valve train, ensuring optimal performance and longevity of the engine.

Role of Part 3966277 Rocker Lever in Engine Systems

The Rocker Lever, specifically part 3966277, is an essential component in the operation of various engine systems. It is part of the rocker lever assembly, which is responsible for transferring motion from the camshaft to the valves.

In the context of the engine’s valve train, the Rocker Lever acts as a force multiplier. When the camshaft lobe rises, it pushes against the rocker lever, which then applies force to open the valve. This mechanism ensures that the valves open and close at the precise moments required for optimal engine performance.

The Rocker Lever is connected to the valve stem via a pushrod in overhead valve (OHV) engines. This setup allows for efficient transmission of motion with minimal loss of energy. In overhead cam (OHC) engines, the rocker lever may directly contact the camshaft, further enhancing the precision of valve actuation.

Additionally, the Rocker Lever plays a role in managing valve clearance. Proper adjustment of the rocker lever ensures that there is no excessive play between the components, which could lead to poor engine performance or damage over time.

In summary, the Rocker Lever, part 3966277, is integral to the efficient and precise operation of the engine’s valve train, ensuring that the valves open and close in sync with the engine’s requirements.

Conclusion

The Cummins 3966277 Rocker Lever is a critical component in the valve train system of heavy-duty truck engines. Its precise design, high-quality materials, and robust construction ensure reliable operation under demanding conditions. Proper installation, regular maintenance, and understanding its role in the engine system are essential for optimal engine performance and longevity.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.