This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

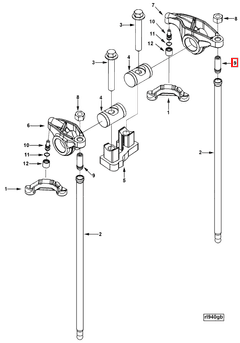

The Rocker Lever Adjusting Screw, identified by part number 3991067, is a component manufactured by Cummins, a well-established name in the engine manufacturing industry. This screw plays a role in the engine’s valve train system by facilitating the adjustment of valve clearance, which is vital for the proper operation of the engine. Cummins is recognized for its commitment to quality and innovation in engine technology, making this adjusting screw a reliable component for maintaining engine performance 1.

Function and Operation

The Rocker Lever Adjusting Screw operates within the engine’s valve train system to maintain proper valve clearance. This clearance is the gap between the valve and the rocker arm when the valve is in its closed position. The screw allows for fine adjustments to this clearance, ensuring that the valve opens and closes at the correct times in relation to the engine’s piston movement. Proper valve timing is crucial for engine efficiency and performance, as it affects combustion efficiency and overall engine operation 2.

Key Features

The design and material characteristics of the Rocker Lever Adjusting Screw contribute to its durability and precision. Crafted from high-quality materials, this screw is engineered to withstand the high stresses and temperatures within the engine environment. Its design ensures accurate adjustments, which are necessary for maintaining optimal valve clearance. The precision engineering of this component reflects Cummins’ commitment to producing parts that meet rigorous standards of quality and performance.

Role in Truck Operation

In the context of commercial trucks, the Rocker Lever Adjusting Screw plays a role in ensuring efficient engine performance and reliability. By maintaining the correct valve clearance, it helps to ensure that the engine operates smoothly and efficiently. This is particularly important in heavy-duty applications, where engine performance directly impacts the truck’s overall efficiency and reliability. Proper maintenance of valve clearance can lead to improved fuel efficiency, reduced emissions, and extended engine life 3.

Benefits

The advantages provided by the Rocker Lever Adjusting Screw include improved engine efficiency, reduced maintenance requirements, and enhanced overall performance. By ensuring that valve clearance is maintained within specified limits, this screw contributes to more efficient combustion, which can lead to better fuel economy. Additionally, by facilitating easy adjustments, it reduces the need for frequent maintenance, allowing for more uptime and less downtime for commercial trucks. The enhanced performance and reliability of the engine also contribute to the overall effectiveness of the truck in its intended application.

Troubleshooting and Maintenance

Identifying common issues related to the Rocker Lever Adjusting Screw involves monitoring engine performance and listening for unusual noises that may indicate valve train problems. Diagnostic procedures may include checking valve clearance and inspecting the screw for signs of wear or damage. Maintenance practices to ensure optimal functionality include regular inspections and adjustments as necessary, following the manufacturer’s guidelines. Proper maintenance of this component is key to preventing more serious engine issues and ensuring the longevity of the engine.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation for quality, durability, and innovation in the commercial truck industry. The company offers a wide range of products and services designed to meet the needs of various industries, including transportation, construction, and power generation. Cummins’ commitment to excellence is reflected in its products, including the Rocker Lever Adjusting Screw, which is designed to meet the demanding requirements of commercial engine applications.

Cummins Rocker Lever Adjusting Screw 3991067 Compatibility

The Cummins Rocker Lever Adjusting Screw part number 3991067 is a critical component in maintaining the proper valve clearance in various Cummins engine models. This screw is essential for ensuring that the engine operates smoothly and efficiently by allowing for precise adjustments to the rocker arm clearance.

Compatible Engines

B Series Engines

- B4.5 RGT

- B6.7 CM2350 B135B

- B6.7 CM2670 B153B

- B6.7 CM2670 B164C

- B6.7 G CMOH

ISB Series Engines

- ISB (Chrysler)

- ISB CM2150

- ISB CM550

- ISB CM850

- ISB/ISD4.5 CM2150 B119

- ISB/ISD6.7 CM2150 SN

- ISB5.9 CM2880 B110

- ISB6.7 CM2250

- ISB6.7 CM2350 B101

- ISB6.7 G CM2180 B118

ISBE Series Engines

- ISBE CM2150

- ISBE CM800

- ISBE4 CM850

ISC Series Engines

- ISC CM554

- ISC CM850

ISD Series Engines

- ISD4.5 CM2220 D108

ISL Series Engines

- ISL CM554

- ISL9 CM2150 SN

QSB Series Engines

- QSB4.5 CM2250 EC

This part is designed to fit seamlessly into the specified engine models, ensuring that the valve clearance is maintained at optimal levels. Proper installation and adjustment of the rocker lever adjusting screw are crucial for the longevity and performance of the engine.

Role of Part 3991067 Rocker Lever Adjusting Screw in Engine Systems

The Rocker Lever Adjusting Screw, identified by part number 3991067, is integral to the precise functioning of several engine components. When integrated into a Long Block or Long Block Kit, this screw plays a significant role in maintaining the optimal performance of the Rocker Lever and Rocker Lever Assembly.

In the context of a Long Block, which typically includes the cylinder block, crankshaft, pistons, and other essential components, the Rocker Lever Adjusting Screw ensures that the rocker levers are correctly positioned. This positioning is vital for the efficient transfer of motion from the camshaft to the valves, which is fundamental for the engine’s combustion process.

Within a Long Block Kit, which often comes with additional components like gaskets and seals, the Rocker Lever Adjusting Screw facilitates the fine-tuning of the Rocker Lever Assembly. This assembly consists of the rocker levers, pushrods, and other associated parts. The screw allows for adjustments that ensure the rocker levers maintain the correct clearance between the camshaft and the valves. This clearance is essential for preventing valvetrain noise and ensuring smooth engine operation.

The Rocker Lever Adjusting Screw is also key in the overall Rocker Lever mechanism. By allowing for micro-adjustments, it helps in achieving the precise valve timing necessary for optimal engine performance. This is particularly important in high-performance engines where even minor deviations can significantly impact efficiency and power output.

Conclusion

In summary, the Rocker Lever Adjusting Screw part number 3991067 is a component that enhances the functionality and reliability of the rocker lever system in engine assemblies, contributing to the overall performance and longevity of the engine. Its role in maintaining proper valve clearance is crucial for efficient engine operation, particularly in heavy-duty applications. The precision engineering and high-quality materials used in its construction reflect Cummins’ commitment to excellence in engine technology.

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.