This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

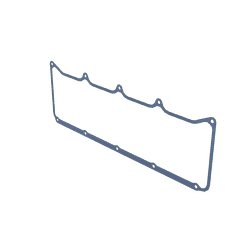

The Rocker Lever Housing Gasket, identified by Part #4067552, is a component manufactured by Cummins, a leading provider of diesel engines and related technologies. This gasket plays a significant role in the operation of heavy-duty truck engines, ensuring the integrity of the valve train system. Its design and function are essential for maintaining engine performance and longevity.

Function and Operation

The Rocker Lever Housing Gasket is integral to the engine’s valve train system. It is positioned between the rocker lever housing and the cylinder head, where it serves to create a seal that prevents oil from leaking into the combustion chamber. This seal is vital for maintaining the proper lubrication of moving parts while ensuring that oil does not contaminate the combustion process. The gasket’s role in sealing contributes to the overall efficiency and reliability of the engine 1.

Key Features

The Rocker Lever Housing Gasket is designed with specific characteristics to enhance its performance and durability. It is typically made from a composite material that offers both flexibility and strength. The gasket’s shape is engineered to fit precisely within the contours of the rocker lever housing and cylinder head, ensuring a tight seal. Additionally, the material composition is chosen to withstand the high temperatures and pressures present in the engine environment, contributing to the gasket’s longevity 2.

Benefits

The use of the Rocker Lever Housing Gasket offers several advantages. By maintaining a secure seal, it helps to improve engine efficiency by ensuring that oil remains within the lubrication system. This reduces oil consumption and prevents the need for frequent top-ups. Furthermore, the gasket contributes to enhanced overall engine performance by supporting the proper operation of the valve train system, which is crucial for the engine’s power output and fuel efficiency 3.

Installation and Maintenance

Proper installation of the Rocker Lever Housing Gasket is crucial for its effectiveness. It should be installed according to the manufacturer’s specifications, which may include specific torque settings for the bolts that secure the rocker lever housing. Careful attention to these details during installation helps to ensure the gasket forms a proper seal. For maintenance, regular inspections are recommended to check for signs of wear or damage. Replacing the gasket at recommended intervals or when signs of failure are detected can help maintain engine performance and prevent issues such as oil leaks 4.

Troubleshooting Common Issues

Common issues associated with the Rocker Lever Housing Gasket include oil leaks and gasket failure. These problems can often be identified through visual inspection or by monitoring engine performance and oil levels. Diagnostic procedures may involve checking for oil residue around the gasket area or performing a compression test to assess the engine’s sealing integrity. Solutions typically involve replacing the gasket with a new one, ensuring that the installation is performed correctly to prevent recurrence of the issue 5.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including diesel and natural gas engines, as well as related technologies. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the automotive industry, particularly in the realm of heavy-duty truck components. The company’s commitment to excellence is reflected in its product offerings, which are designed to meet the demanding requirements of commercial and industrial applications 6.

Role of Part 4067552 Rocker Lever Housing Gasket in Engine Systems

The 4067552 Rocker Lever Housing Gasket is an essential component in ensuring the integrity and efficiency of various engine systems. This gasket is specifically designed to seal the interface between the rocker lever housing and the engine block or head, preventing oil and coolant leaks while maintaining proper pressure within the system.

Integration with Base Parts and Engine Brake

When installing base parts, the Rocker Lever Housing Gasket ensures a tight seal between the rocker lever housing and the engine block. This is particularly important in systems equipped with an engine brake, where maintaining consistent pressure and preventing fluid leaks is vital for the brake’s effective operation. The gasket helps in sustaining the necessary conditions for the engine brake to function smoothly without any interference from external contaminants 7.

Interaction with Lever and Rocker Components

The gasket plays a significant role in the assembly of the lever and rocker components. It ensures that the rocker arms, which are pivotal in transferring motion from the camshaft to the valves, operate in a sealed environment. This sealing prevents any lubricants from escaping, which could otherwise lead to decreased performance and increased wear on the rocker arms and levers 8.

Contribution to Rocker Housing and Mounting

In the context of rocker housing and its mounting, the 4067552 gasket is instrumental in creating a secure and leak-proof connection. The rocker housing mounting relies on this gasket to ensure that the housing is firmly attached to the engine block without any gaps that could allow oil or coolant to seep through. This is essential for maintaining the structural integrity and operational efficiency of the rocker housing 9.

Role in Rocker Housings and Gasket Sets

When dealing with rocker housings, especially in configurations that require a single head gasket set or an upper engine gasket kit, the Rocker Lever Housing Gasket complements these components by providing an additional layer of sealing. This is particularly important in upper engine gasket sets where multiple gaskets work together to ensure the entire upper section of the engine remains sealed and operates efficiently 10.

Application in VT903 Short Block Kit

In the VT903 Short Block Kit, the inclusion of the 4067552 gasket is a standard practice. This kit often requires precise sealing around the rocker lever housing to ensure that the short block, which includes the cylinder block, crankshaft, pistons, and other lower end components, functions seamlessly with the upper end components like the rocker lever housing. The gasket ensures that the transition between the lower and upper engine sections is smooth and leak-free, contributing to the overall reliability and performance of the engine 11.

Conclusion

The Rocker Lever Housing Gasket part number 4067552, manufactured by Cummins, is a critical component in the operation and maintenance of heavy-duty truck engines. Its role in sealing the valve train system, preventing oil leaks, and ensuring engine efficiency cannot be overstated. Proper installation, regular maintenance, and timely replacement of this part are essential for maintaining optimal engine performance and longevity.

-

Garrett, T.K., Newton, K., & Steeds, W. (2001). The Motor Vehicle. Reed Educational and Professional Publishing Ltd.

↩ -

Norman, A. (2016). Diesel Technology Fundamentals Service Repair Eighth Edition. The Goodheart-Willcox Company Inc.

↩ -

Lakshminarayanan, P.A., & Agarwal, A.K. (2019). Design and Development of Heavy Duty Diesel Engines: A Handbook. Springer.

↩ -

Cummins Inc. (n.d.). Owners Manual for ISB5.9 CM2880 B140, Bulletin Number 5411231.

↩ -

Cummins Inc. (n.d.). Owners Manual for ISB5.9 CM2880 B140, Bulletin Number 5411231.

↩ -

Cummins Inc. (n.d.). Company Overview. Retrieved from Cummins Official Website

↩ -

Cummins Inc. (n.d.). Owners Manual for ISB5.9 CM2880 B140, Bulletin Number 5411231.

↩ -

Cummins Inc. (n.d.). Owners Manual for ISB5.9 CM2880 B140, Bulletin Number 5411231.

↩ -

Cummins Inc. (n.d.). Owners Manual for ISB5.9 CM2880 B140, Bulletin Number 5411231.

↩ -

Cummins Inc. (n.d.). Owners Manual for ISB5.9 CM2880 B140, Bulletin Number 5411231.

↩ -

Cummins Inc. (n.d.). Owners Manual for ISB5.9 CM2880 B140, Bulletin Number 5411231.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.