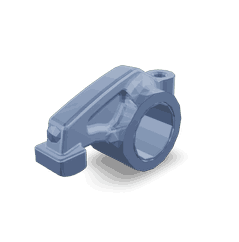

4309637

Rocker Lever

Cummins®

AVAILABLE

More than 10 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 4309637 Rocker Lever is a critical component in the operation of heavy-duty trucks, integral to the engine system by facilitating the movement of valves in response to camshaft actions.

Basic Concepts of Rocker Levers

A rocker lever is a simple machine that amplifies force through mechanical advantage. In engines, it transfers motion from the camshaft to the valves, ensuring valves open and close with the precision and force required for optimal engine performance 1.

Purpose of the 4309637 Rocker Lever

This Cummins part is designed to interact with valves and camshafts, translating the rotational motion of the camshaft into the linear motion needed to operate the valves. This ensures the engine operates efficiently, with valves opening and closing at the correct times and with the appropriate force 2.

Key Features

The 4309637 is constructed from high-strength alloys, offering resilience against high stresses and temperatures. Its design includes precision machining for accurate fit and function, and surface treatments to reduce friction and wear, enhancing durability and performance 3.

Benefits

This part offers improved engine efficiency through precise valve operation, reduced wear on associated components, and enhanced overall truck performance. Its design contributes to smoother engine operation and potentially extends the lifespan of interacting engine components.

Installation and Integration

Proper installation of the 4309637 is crucial for its effective function. It is compatible with various engine models, requiring correct alignment and adherence to torque specifications for integration. Following detailed installation guidelines is important to maintain engine performance integrity.

Troubleshooting and Maintenance

Common issues with rocker levers include noise, uneven valve operation, or excessive wear. Early identification of these problems can prevent significant engine damage. Regular maintenance, such as checking for wear and ensuring proper lubrication, is essential for the longevity and optimal performance of the 4309637.

Performance Enhancements

Modifications or upgrades to the 4309637 can impact engine performance. Aftermarket options may offer improvements in material strength, design efficiency, or compatibility with performance-oriented engine modifications, leading to increased engine efficiency, power output, and durability.

Cummins Corporation

Cummins Inc. is renowned for its engine components, known for innovation, quality, and reliability. The company’s commitment to advancing engine technology is evident in its wide range of products, recognized for their performance and durability.

Compatibility with Cummins Engines

The 4309637 is designed for compatibility with various Cummins engine models, including the QST30, CM2350, and T101. It ensures proper valve operation and overall engine performance, highlighting Cummins’ focus on quality and standardization.

Role of 4309637 in Engine Systems

In engine systems, the 4309637 plays a vital role in the valve train, ensuring efficient valve operation. It interacts with camshafts, lifters, and valve springs to maintain consistent valve operation under varying engine speeds and loads, contributing to engine balance and performance.

Interaction with Camshaft and Lifters

The Rocker Lever is positioned between the camshaft and the valves, amplifying the motion from the camshaft lobes to open the valves with the necessary force.

Connection to Pushrods

In pushrod engines, the Rocker Lever is connected to pushrods, converting linear motion from the camshaft into rotational force to open the valves.

Role in Overhead Cam Engines

In overhead cam engines, the Rocker Levers are directly actuated by the camshaft, providing precise valve control without the need for pushrods.

Valve Operation and Integration with Valve Springs

The primary function of the Rocker Lever is to ensure valves open and close at the correct times and with the appropriate force. Valve springs work with the Rocker Lever to ensure valves close properly, synchronized with the camshaft’s rotation.

Contribution to Engine Balance

The Rocker Lever contributes to engine balance by evenly distributing forces, maintaining smooth operation, and reducing wear on other components.

Conclusion

The 4309637 Rocker Lever is a key component in the valve train, essential for precise and efficient valve operation in both pushrod and overhead cam engine systems. Its interaction with camshafts, lifters, pushrods, and valve springs is crucial for engine performance and longevity.

-

Reif, K. (2015). Gasoline Engine Management Systems and Components. Springer Vieweg.

↩ -

Bell, J. A. (2014). Modern Diesel Technology Electricity Electronics. Delmar Cengage Learning.

↩ -

Lakshminarayanan, P. A., & Kumar, A. (2020). Design and Development of Heavy Duty Diesel Engines: A Handbook. Springer Nature.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.