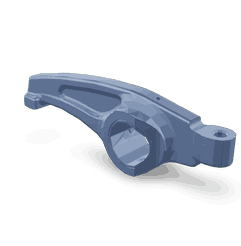

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 4323303 Rocker Lever is a component designed for use in commercial truck engines. It serves a specific function within the engine’s valve train, contributing to the overall operation and efficiency of the truck. Understanding its role and significance is important for maintaining and optimizing truck performance.

Basic Concepts of Rocker Levers

A rocker lever, also known as a rocker arm, is a mechanical component used in internal combustion engines. It acts as a lever that amplifies the motion of the camshaft to open and close the engine’s valves. This mechanism allows for precise control over the timing and duration of valve events, which is crucial for engine operation. Rocker levers are commonly found in overhead valve (OHV) and overhead cam (OHC) engine designs, playing a vital role in the engine’s valve train system 1.

Purpose of the 4323303 Rocker Lever

The 4323303 Rocker Lever is designed to facilitate the operation of the valves in a truck engine. It interacts with the camshaft and pushrods to transfer motion to the valves, ensuring they open and close at the correct times. This component is integral to the engine’s ability to intake air and fuel and exhaust combustion gases efficiently. Its design allows for adjustments to valve clearance, which is important for maintaining engine performance over time 2.

Key Features

The 4323303 Rocker Lever is constructed from high-quality materials to ensure durability and reliability. Its design includes features such as a hardened contact surface for interaction with the valve stem and a pivot point that allows for smooth operation. The lever is engineered to withstand the high stresses and temperatures present in a truck engine environment, contributing to its longevity and performance 3.

Benefits

The use of the 4323303 Rocker Lever in a truck engine offers several advantages. It contributes to improved engine efficiency by ensuring precise valve operation. The durable construction of the lever enhances the engine’s reliability, reducing the likelihood of failures. Additionally, the design of the lever allows for easy adjustment of valve clearance, which can help maintain engine performance throughout the vehicle’s lifespan.

Installation and Integration

Proper installation of the 4323303 Rocker Lever is important for ensuring optimal engine performance. It should be installed according to the manufacturer’s specifications, with attention to torque settings and alignment. Integration into the engine requires careful consideration of the lever’s interaction with other components, such as the camshaft, pushrods, and valves, to ensure smooth operation and efficient valve timing.

Troubleshooting and Maintenance

Common issues with the 4323303 Rocker Lever may include wear at the pivot point or contact surface, leading to noisy operation or valve train problems. Regular inspection and maintenance, including checking for proper clearance and lubrication, are important practices to ensure the longevity and optimal performance of the lever. Diagnostic tips involve listening for unusual noises from the valve train and performing visual inspections for signs of wear or damage.

Performance Impact

The 4323303 Rocker Lever plays a role in influencing engine performance by ensuring efficient valve operation. Proper function of the lever contributes to fuel efficiency and overall engine reliability. Its impact on engine performance underscores the importance of using high-quality components in the valve train system.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins has established a strong reputation in the commercial truck industry. The company’s product range includes a variety of engine and component solutions designed to meet the demanding requirements of commercial applications.

Compatibility of Rocker Lever Part 4323303 with Cummins Engines

The Rocker Lever part number 4323303, manufactured by Cummins, is designed to fit seamlessly with several Cummins engine models. This part is integral to the engine’s valve train system, ensuring proper valve operation and overall engine performance.

QST30 Engine

The QST30 engine is one of the models compatible with the Rocker Lever part 4323303. This engine is known for its robust construction and reliability, making it suitable for various industrial applications. The Rocker Lever in this engine model ensures smooth and efficient valve actuation, contributing to the engine’s overall efficiency and longevity.

CM2350 and T101 Engines

The CM2350 and T101 engines also utilize the Rocker Lever part 4323303. These engines are part of Cummins’ lineup of medium-duty engines, designed to deliver high performance and durability in demanding environments. The Rocker Lever in these engines plays a crucial role in maintaining the precise timing and operation of the engine’s valves, which is essential for optimal performance and fuel efficiency.

Grouping of Compatible Engines

When considering the compatibility of the Rocker Lever part 4323303, it is important to note that the QST30 engine, while distinct in its design and application, shares the same critical requirement for a reliable valve train system as the CM2350 and T101 engines. The Rocker Lever part 4323303 is engineered to meet these requirements across all three engine models, ensuring a consistent fit and function.

By understanding the compatibility of the Rocker Lever part 4323303 with the QST30, CM2350, and T101 engines, technicians and operators can confidently select and install this part, knowing it is designed to work seamlessly with these Cummins engine models.

Integration of Part 4323303 Rocker Lever in Engine Systems

The part 4323303 Rocker Lever is an essential component in the operation of various engine systems, facilitating the transfer of motion from the camshaft to the valves. Its role is significant in ensuring the precise timing and efficiency of valve operation, which is fundamental to the engine’s performance.

Valve Train Mechanism

In the valve train mechanism, the Rocker Lever (part 4323303) acts as a mediator between the camshaft and the valves. As the camshaft rotates, it pushes against the rocker lever, which then amplifies this motion to open the valves. This amplification is necessary because the camshaft’s movement is typically small, and the valves require a more substantial motion to open and close effectively.

Interaction with Pushrods and Lifters

In overhead valve (OHV) engines, the Rocker Lever is connected to pushrods and lifters. The lifter, positioned at the base of the engine, makes contact with the camshaft. As the camshaft lobe pushes the lifter upward, this motion is transmitted through the pushrod to the Rocker Lever. The Rocker Lever then converts this linear motion into a rotational force that opens the valve.

Overhead Cam (OHC) Engines

In overhead cam (OHC) engines, the Rocker Lever’s role is slightly different. Here, the camshaft is positioned closer to the valves, often directly above them. The Rocker Lever in OHC engines typically has a more direct interaction with the camshaft, converting the camshaft’s rotational motion into the necessary linear motion to operate the valves.

Importance in Valve Timing

The precise operation of the Rocker Lever is vital for maintaining correct valve timing. This timing is crucial for the engine’s efficiency and performance. The Rocker Lever ensures that the valves open and close at the exact moments required for optimal combustion and exhaust processes.

Role in Valve Clearance Adjustment

The Rocker Lever also plays a role in valve clearance adjustment. In many engine designs, the gap between the rocker lever and the valve stem needs to be precisely set. This clearance ensures that the valve operates without excessive wear or noise and opens and closes at the correct times.

Contribution to Engine Efficiency

By ensuring efficient valve operation, the Rocker Lever contributes to overall engine efficiency. Proper valve timing and operation lead to better fuel combustion, reduced emissions, and improved engine performance. The Rocker Lever’s role in this process is therefore integral to the engine’s functionality and longevity.

Conclusion

The Cummins 4323303 Rocker Lever is a critical component in the valve train system of commercial truck engines. Its role in amplifying camshaft motion to operate the valves ensures precise timing and efficient engine performance. The durable construction and design of this part contribute to the reliability and longevity of the engine. Proper installation, maintenance, and understanding of its function are essential for optimizing engine performance and ensuring the longevity of the vehicle.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.