This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

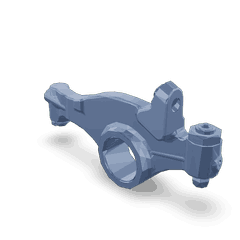

The Rocker Top Level Assembly Lever, identified by Part #4330226, is a component manufactured by Cummins, a leader in diesel engines and related technologies. This part is integral to the operation of heavy-duty truck engines, contributing to their efficiency and performance. Cummins is recognized for its commitment to quality and innovation in the automotive industry, making this assembly lever a reliable choice for truck manufacturers and operators.

Basic Concepts and Functionality

The Rocker Top Level Assembly Lever is a mechanical component within the engine’s valve train system. It consists of several parts, including the lever arm, pivot point, and attachment points for the pushrod and rocker arm. The lever operates by transferring motion from the pushrod to the rocker arm, which in turn actuates the engine’s valves. This transfer of motion is crucial for the precise timing of valve opening and closing, which is fundamental to the engine’s combustion process 1.

Purpose and Role in Truck Operation

In the context of heavy-duty truck engines, the Rocker Top Level Assembly Lever plays a significant role in valve operation. It ensures that the valves open and close at the correct times during the engine’s operation cycle. This timing is vital for maintaining engine performance, fuel efficiency, and emissions control. By facilitating the accurate movement of the valves, the assembly lever contributes to the overall efficiency and reliability of the engine 2.

Key Features

The Rocker Top Level Assembly Lever is designed with several key features that enhance its functionality. It is typically made from high-strength materials to withstand the rigorous conditions within an engine. The design includes precise machining for smooth operation and durability. Additionally, the lever may feature specific geometry and surface treatments to reduce friction and wear, ensuring long-term performance 3.

Benefits

The incorporation of the Rocker Top Level Assembly Lever into heavy-duty truck engines offers several benefits. It contributes to improved engine efficiency by ensuring precise valve timing. The durable construction of the lever enhances the engine’s reliability, reducing the likelihood of mechanical failures. Furthermore, the design of the lever can lead to reduced maintenance requirements, providing cost savings over the engine’s lifespan 4.

Installation Process

Installing the Rocker Top Level Assembly Lever requires careful attention to detail. The process involves removing the old lever, if present, and ensuring the engine components are clean and free of debris. The new lever is then positioned and secured in place, with attention paid to aligning it correctly with the pushrod and rocker arm. Torque specifications provided by the manufacturer should be followed to ensure proper installation. It is also important to verify the lever’s operation before finalizing the installation.

Common Issues and Troubleshooting

Common issues with the Rocker Top Level Assembly Lever may include wear, misalignment, or damage due to debris. Troubleshooting these problems involves inspecting the lever for signs of wear or damage, ensuring it is correctly aligned with the pushrod and rocker arm, and cleaning the engine components to remove any debris. In some cases, replacement of the lever may be necessary to restore proper engine operation.

Maintenance Tips

To ensure the optimal performance and longevity of the Rocker Top Level Assembly Lever, regular maintenance is recommended. This includes periodic inspection for signs of wear or damage, ensuring proper alignment, and keeping the engine components clean. Lubrication of moving parts, as specified by the manufacturer, can also help reduce friction and wear. Following these maintenance practices can help prevent issues and extend the service life of the lever.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, innovation, and reliability in the automotive and heavy-duty truck industries. The company’s commitment to manufacturing high-quality components is evident in its wide range of products, including the Rocker Top Level Assembly Lever, which is designed to meet the demanding requirements of heavy-duty applications.

Compatibility of 4330226 with Cummins Engines

The Cummins Rocker Top Level Assembly Lever, identified by part number 4330226, is a critical component in the valve train system of several Cummins engines. This part is designed to ensure precise valve operation, which is crucial for maintaining engine performance and longevity. Here’s how it fits with specific Cummins engines:

ISX12 G and CM2180 Engines

The ISX12 G and CM2180 engines are part of Cummins’ lineup of heavy-duty diesel engines, known for their robust performance and reliability in demanding applications. The Rocker Top Level Assembly Lever in these engines is engineered to withstand high stress and frequent operation, ensuring smooth and reliable valve actuation. This lever plays a pivotal role in the valve train mechanism, directly affecting the engine’s efficiency and power output.

EJ Engines

The EJ engines, another segment of Cummins’ engine portfolio, also benefit from the precision and durability of the 4330226 Rocker Top Level Assembly Lever. These engines are typically used in a variety of applications, from construction to transportation, where reliability and performance are paramount. The lever’s design in these engines ensures that the valve timing remains accurate, contributing to the engine’s overall efficiency and longevity.

Application Considerations

When considering the use of the 4330226 Rocker Top Level Assembly Lever in Cummins engines, it is essential to ensure that the part is correctly installed and maintained. Proper installation and regular maintenance can significantly extend the life of the engine and prevent potential failures related to valve operation. Technicians and mechanics should refer to Cummins’ technical manuals and guidelines for the correct procedures and specifications when working with this component.

Role of 4330226 in Engine Systems

The 4330226 Rocker Top Level Assembly Lever is an integral component in the operation of various engine systems. It works in conjunction with several other components to ensure the smooth and efficient functioning of the engine.

Interaction with the Rocker Arm

The Rocker Top Level Assembly Lever interfaces directly with the rocker arm. This interaction is essential for transferring motion from the camshaft to the valve. As the camshaft rotates, it pushes against the rocker arm, which in turn pivots on its fulcrum. The Rocker Top Level Assembly Lever amplifies this motion, ensuring that the valve opens and closes with the precision required for optimal engine performance.

Coordination with the Valve Train

Within the valve train, the Rocker Top Level Assembly Lever plays a significant role. It ensures that the valves open and close in sync with the engine’s timing. This coordination is vital for maintaining the engine’s efficiency and power output. The lever’s design allows for minimal friction and wear, contributing to the longevity of the valve train components.

Integration with the Camshaft

The camshaft’s lobes are designed to interact with the Rocker Top Level Assembly Lever. As the camshaft rotates, it engages with the lever, transmitting motion to the rocker arm. This interaction is a fundamental part of the engine’s operation, ensuring that the valves open and close at the correct times in the engine cycle.

Support from the Pushrod

In overhead valve (OHV) engine configurations, the pushrod transmits motion from the camshaft to the Rocker Top Level Assembly Lever. The lever then converts this linear motion into rotational motion for the rocker arm. This setup allows for efficient valve actuation, even in engines with complex valve train geometries.

Contribution to Engine Performance

The Rocker Top Level Assembly Lever’s role extends beyond simple motion transfer. It contributes to the engine’s overall performance by ensuring that the valve events are precisely timed. This precision is essential for maximizing fuel efficiency, power output, and reducing emissions. The lever’s design also helps in minimizing noise and vibration, leading to a smoother engine operation.

Conclusion

In summary, the 4330226 Rocker Top Level Assembly Lever is a key component in the engine’s valve train system. Its interaction with the rocker arm, camshaft, and pushrod ensures that the valves operate with the required timing and precision, contributing to the engine’s efficiency and performance.

-

Hilgers, Michael. Fuel Consumption and Consumption Optimization, Second Edition. Springer Nature, 2023.

↩ -

Reif, Konrad. Diesel Engine Management Systems and Components. Springer, 2014.

↩ -

Trzesniowski, Michael. The Complete Vehicle. Springer Nature, 2023.

↩ -

Reif, Konrad. Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg, 2014.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.