4330239

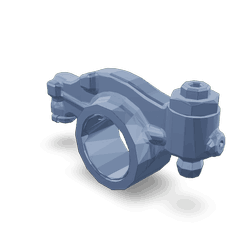

Rocker Top Level Assembly Lever

Cummins®

IN STOCK

4 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Rocker Top Level Assembly Lever, identified by part number 4330239, is a component manufactured by Cummins, a well-established name in the automotive industry, particularly known for its heavy-duty truck engines. This lever is integral to the operation of these engines, contributing to their overall performance and efficiency.

Function and Operation

The Rocker Top Level Assembly Lever operates within the engine’s valve train mechanism. It interacts with the camshaft, pushrods, and rocker arms to facilitate the opening and closing of the engine’s valves. This lever’s precise movement ensures that the valves open and close at the correct times, allowing for the intake of air and fuel and the expulsion of exhaust gases. Its operation is synchronized with the engine’s rotational speed, ensuring efficient combustion and power delivery 1.

Purpose of the Rocker Top Level Assembly Lever

The specific role of the Rocker Top Level Assembly Lever in a truck engine is to enhance the efficiency of the valve train mechanism. By ensuring that the valves operate in harmony with the engine’s cycles, this lever contributes to the engine’s performance and efficiency. Its design and function are tailored to withstand the rigorous demands of heavy-duty truck engines, promoting smooth and reliable operation 2.

Key Features

The Rocker Top Level Assembly Lever is characterized by several key features that enhance its functionality. It is constructed from durable materials, ensuring longevity and resistance to wear. Its design includes precise tolerances and smooth surfaces to minimize friction and ensure accurate valve operation. Additionally, the lever may incorporate features such as anti-rotation pins or enhanced lubrication points to further improve its performance and durability 3.

Benefits

Utilizing the Rocker Top Level Assembly Lever offers several benefits. It contributes to improved engine performance by ensuring precise valve timing and operation. Its durable construction and design features enhance the engine’s reliability and longevity. Furthermore, the lever’s efficient operation can lead to better fuel economy and reduced emissions, aligning with the goals of modern heavy-duty truck engines.

Installation Process

Installing the Rocker Top Level Assembly Lever requires careful attention to detail. The process involves removing the old lever, if present, and ensuring the valve train components are clean and free of debris. The new lever should be installed according to the manufacturer’s specifications, with attention paid to torque settings and alignment. It is important to verify that the lever operates smoothly and that all components are securely in place before finalizing the installation.

Maintenance Tips

To ensure the optimal performance and longevity of the Rocker Top Level Assembly Lever, regular maintenance is recommended. This includes periodic inspections for signs of wear or damage, ensuring that all moving parts are lubricated according to the manufacturer’s guidelines, and verifying that the lever operates smoothly without excessive play or noise. Adhering to these maintenance practices can help prevent issues and ensure the lever continues to function effectively.

Troubleshooting Common Issues

Common issues associated with the Rocker Top Level Assembly Lever may include noise, reduced engine performance, or valve train malfunctions. Troubleshooting these issues involves inspecting the lever and related components for signs of wear, damage, or misalignment. Addressing any identified issues promptly, whether through adjustment, lubrication, or replacement, can help restore the engine’s performance and prevent further complications.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a strong reputation in the automotive industry, particularly for heavy-duty truck components, Cummins is known for its commitment to quality, innovation, and customer satisfaction. The company’s extensive product offerings and technological advancements have made it a preferred choice for professionals in the automotive and transportation sectors.

Compatibility of 4330239 with Cummins Engines

The 4330239 Rocker Top Level Assembly Lever is compatible with specific Cummins engines, including the ISX12 G and CM2180 EJ. This part plays a pivotal role in the operation of the engine’s valves, ensuring that they open and close at the correct times and with the appropriate force.

ISX12 G

The ISX12 G engine, known for its robust performance and reliability, integrates the Rocker Top Level Assembly Lever as part of its intricate valve train mechanism. This lever is essential for the precise movement of the rocker arms, which in turn activate the engine’s valves. The design and placement of this lever are tailored to the specific needs of the ISX12 G, ensuring optimal engine performance and longevity.

CM2180 EJ

Similarly, the CM2180 EJ engine incorporates the Rocker Top Level Assembly Lever in its valve train system. This engine, designed for heavy-duty applications, relies on the accurate and efficient operation of its valves to maintain power and efficiency. The lever’s role in the CM2180 EJ is to facilitate the smooth and reliable movement of the rocker arms, contributing to the engine’s overall performance and durability.

Role of 4330239 in Engine Systems

The 4330239 Rocker Top Level Assembly Lever is an integral component in the operation of various engine systems. It interfaces directly with the rocker arm, which is responsible for transferring the motion from the camshaft to the valves. This transfer is essential for the precise timing of valve opening and closing, which in turn affects the engine’s performance and efficiency.

When the camshaft rotates, it pushes against the rocker arm. The 4330239 amplifies this motion, ensuring that the valves open and close with the correct force and timing. This lever is typically mounted on a pivot point, allowing it to rock back and forth as the camshaft lobes engage with the rocker arm.

The lever’s design ensures minimal friction and maximum durability, which is vital for the longevity of the engine. It works in conjunction with other components such as the valve springs, which return the valves to their closed position after being opened. The interaction between the 4330239 and the valve springs must be finely tuned to prevent issues like valve float, where the valve fails to close properly at high engine speeds.

Additionally, the lever plays a role in maintaining the proper clearance between the valve and the piston. This clearance is essential to prevent contact between the two, which could lead to severe engine damage. The lever’s precise movement ensures that the valves open just enough to allow the intake and exhaust gases to flow without interfering with the piston’s travel.

Conclusion

In summary, the 4330239 Rocker Top Level Assembly Lever is a key element in the valve train system, ensuring that the valves operate efficiently and reliably. Its interaction with the rocker arm, camshaft, and valve springs is essential for the overall performance and durability of the engine.

-

Haoran Hu, Rudy Smaling, Simon Baseley, Heavy-Duty Wheeled Vehicles, SAE International, 2014.

↩ -

John Dixon, Modern Diesel Technology: Heating, Ventilation, Air Conditioning, Refrigeration, 2nd Edition, Cengage Learning, 2014.

↩ -

Karsten Berns, Klaus Dressler, Patrick Fleischmann, Daniel Grges, Ralf Kalmar, Bernd Sauer, Nicole Stephan, Roman Teutsch, Martin Thul, Proceedings of the 5th Commercial Vehicle Technology Symposium CVT, Springer, 2018.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.