This is an oversize product. Additional shipping fees may apply.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

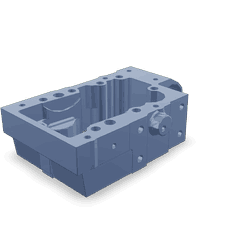

The 4371945 Rocker Lever Housing is a component manufactured by Cummins, a prominent entity in the automotive industry, especially renowned for its diesel engines and components. This housing is pivotal in the operation of heavy-duty trucks, ensuring the efficient functioning of the valve train mechanism. Its design and engineering are tailored to meet the demanding requirements of heavy-duty applications, contributing to the overall performance and reliability of Cummins engines 1.

Function and Operation

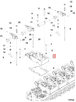

This Cummins part is integral to the valve train mechanism in Cummins engines. It serves as a mounting point for rocker arms, which are responsible for transferring motion from the camshaft to the valve stems. This transfer of motion facilitates the precise opening and closing of engine valves, which is essential for the intake and exhaust processes within the engine. The housing ensures that the rocker arms are correctly positioned and supported, allowing for smooth and consistent valve operation 2.

Key Features

The 4371945 is characterized by its robust design and high-quality materials, which contribute to its durability and precision engineering. It is specifically designed to be compatible with Cummins engines, ensuring a perfect fit and optimal performance. The housing is crafted to withstand the high stresses and temperatures encountered in heavy-duty truck applications, providing reliable service over the engine’s lifespan 3.

Benefits

The use of the 4371945 offers several advantages. It enhances engine performance by ensuring that the valve train operates smoothly and efficiently. This contributes to improved engine reliability and longevity, as well as overall engine efficiency and power output. The precision engineering of the housing also helps in reducing wear and tear on associated components, leading to fewer maintenance requirements and lower operational costs 4.

Installation and Maintenance

Proper installation of the 4371945 is vital for its effective operation. It should be installed according to the manufacturer’s torque specifications and alignment procedures to ensure it is securely fastened and correctly positioned. Regular maintenance is recommended to ensure optimal performance and longevity. This includes periodic inspection for signs of wear or damage, ensuring proper lubrication of moving parts, and adhering to recommended replacement intervals to prevent failure and maintain engine efficiency.

Troubleshooting Common Issues

Common issues associated with the 4371945 may include noise, leakage, or malfunction. These problems can often be traced to improper installation, wear and tear, or damage to the housing or associated components. Diagnostic procedures should involve a thorough inspection of the housing and its components, checking for alignment, secure fastening, and signs of wear. Recommended solutions may include re-torquing fasteners, replacing worn components, or, in severe cases, replacing the housing itself to restore proper function.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including diesel and natural gas engines, as well as related technologies. With a history spanning over a century, Cummins has established a reputation for quality, innovation, and reliability in the automotive industry. Its product offerings cater to various sectors, including heavy-duty trucking, construction, agriculture, and power generation, among others. Cummins’ commitment to excellence and customer satisfaction has made it a preferred choice for engine and component solutions in demanding applications.

Compatibility with Cummins Engines

The 4371945, manufactured by Cummins, is designed to fit seamlessly within the architecture of several Cummins engine models. This component is integral to the engine’s valve train system, ensuring the smooth operation of the rocker levers that control the opening and closing of the engine’s valves.

QSK19 CM500 and QSK19G Engines

For the QSK19 CM500 and QSK19G engines, the 4371945 is specifically engineered to align with the unique design and operational parameters of these models. These engines are known for their robust performance and reliability, often used in heavy-duty applications. The housing part ensures that the rocker levers function without obstruction, maintaining the precise timing necessary for optimal engine performance.

The fitment of this part is critical in these engines, as any misalignment or wear can lead to significant performance issues. The 4371945 is crafted to withstand the high stresses and operational demands of these engines, ensuring longevity and consistent performance.

Role in Engine Systems

The 4371945 is an integral component in the operation of engine systems, specifically in the valve train mechanism. This housing encases the rocker lever, which is pivotal for transferring motion from the camshaft to the valves.

When the camshaft rotates, it pushes on the rocker lever through the cam lobe. The rocker lever, mounted within the 4371945 housing, then amplifies this motion and transfers it to the valve. This transfer ensures that the valve opens and closes at precise intervals, which is essential for the engine’s combustion process.

The housing itself provides a stable and secure environment for the rocker lever, protecting it from external contaminants and ensuring consistent performance. It also facilitates the proper alignment of the rocker lever with other components, such as the pushrod and the valve stem, which is vital for the smooth operation of the valve train.

Conclusion

In summary, the 4371945 plays a significant role in maintaining the integrity and efficiency of the valve train system, ensuring that the engine operates smoothly and effectively. Its robust design, precision engineering, and compatibility with Cummins engines make it a critical component for the reliable operation of heavy-duty trucks and other demanding applications.

-

Hilgers, Michael. The Diesel Engine Second Edition. Springer Nature, 2023.

↩ -

Viskup, Richard. Diesel and Gasoline Engines. IntechOpen, 2020.

↩ -

Heywood, John. Internal Combustion Engine Fundamentals. McGraw-Hill Education, 2019.

↩ -

Department of Energy. Department of Energy Fundamentals Handbook. Department of Energy, 2015.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.