This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

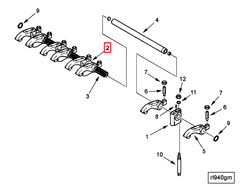

The 4900413 Rocker Lever Support is a component designed by Cummins, a well-established manufacturer in the heavy-duty truck industry. This part is integral to the operation of heavy-duty trucks, contributing to the efficient functioning of the engine. Cummins is renowned for its robust and reliable engine components, and the 4900413 Rocker Lever Support is no exception. This overview will delve into the specifics of this component, its purpose, and its significance within the engine system.

Basic Concepts of Rocker Lever Support

A Rocker Lever Support serves as a pivotal element in the engine’s valve train system. Its primary function is to provide a stable mounting point for the rocker arm, which in turn actuates the engine’s valves. The interaction between the Rocker Lever Support, rocker arm, and valve train is crucial for the precise timing and operation of the engine’s intake and exhaust valves. This component ensures that the rocker arm remains securely in place, allowing for efficient valve actuation and contributing to the overall performance of the engine 1.

Purpose of the 4900413 Rocker Lever Support

The 4900413 Rocker Lever Support plays a role in the operation of a truck engine by supporting the rocker arm as it moves in response to the camshaft’s rotation. This support is vital for the accurate and consistent actuation of the engine’s valves, which is fundamental to the combustion process. By ensuring that the rocker arm operates within the correct parameters, the 4900413 Rocker Lever Support contributes to the engine’s efficiency, power output, and longevity 2.

Key Features

The 4900413 Rocker Lever Support is characterized by several key features that enhance its functionality and durability. It is constructed from high-quality materials, designed to withstand the high stresses and temperatures encountered within an engine environment. The design of the support includes precise machining and tolerances to ensure a secure fit and optimal performance. Additionally, any unique characteristics, such as coatings or specific design elements, are incorporated to further improve its resistance to wear and corrosion 3.

Benefits

The incorporation of the 4900413 Rocker Lever Support into a truck engine offers several benefits. It contributes to improved engine efficiency by ensuring that the valve actuation process is smooth and precise. This, in turn, can lead to enhanced fuel economy and reduced emissions. Furthermore, by providing a stable and durable mounting point for the rocker arm, the 4900413 Rocker Lever Support helps to reduce wear on associated components, leading to extended engine life and reliability 4.

Installation Process

Installing the 4900413 Rocker Lever Support requires careful attention to detail to ensure correct fitting and function. The process involves securing the support in its designated location within the engine, ensuring that it is properly aligned with the rocker arm and other components. Tools required may include torque wrenches and socket sets, and it is important to follow the manufacturer’s guidelines for torque specifications and installation procedures to avoid damage to the component or engine.

Troubleshooting Common Issues

Common issues associated with the 4900413 Rocker Lever Support may include wear, noise, or failure. These problems can often be traced back to improper installation, excessive wear on the component, or issues with the rocker arm or valve train. Troubleshooting steps may involve inspecting the support for signs of wear or damage, checking the alignment and fit of the component, and ensuring that all associated parts are in good condition and properly lubricated.

Maintenance Tips

Regular maintenance of the 4900413 Rocker Lever Support is key to ensuring its longevity and optimal performance. This includes periodic inspection for signs of wear or damage, cleaning the component to remove any buildup of dirt or debris, and ensuring that all fasteners are tight and secure. Following the manufacturer’s recommended maintenance schedule and procedures will help to prevent issues and ensure that the component continues to function effectively.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and innovation in the heavy-duty truck industry. The company’s extensive product range and commitment to customer satisfaction have made it a preferred choice for professionals in the field.

Rocker Lever Support (Part 4900413) Compatibility with Cummins Engines

The Rocker Lever Support part 4900413, manufactured by Cummins, is designed to be compatible with a range of Cummins engines. This part is crucial for maintaining the proper function of the rocker levers, which are integral to the engine’s valve train operation.

A1400 and A1700 Engines

The Rocker Lever Support part 4900413 is specifically engineered to fit the A1400 and A1700 engines. These engines are part of Cummins’ smaller engine series, often used in compact machinery and light-duty applications. The design of the part ensures it can handle the specific load and operational conditions of these engines.

A2000 and A2300 Engines

Similarly, the Rocker Lever Support part 4900413 is also compatible with the A2000 and A2300 engines. These engines are part of Cummins’ medium-duty engine series, typically used in a variety of applications from medium trucks to industrial equipment. The part’s robust design ensures it can withstand the higher demands and operational stresses of these engines.

Grouping for Compatibility

The compatibility of the Rocker Lever Support part 4900413 across the A1400, A1700, A2000, and A2300 engines is due to the standardized design and engineering principles employed by Cummins. This standardization allows for easier maintenance and repair, as the same part can be used across multiple engine models, reducing inventory needs and simplifying the supply chain.

Role of Part 4900413 Rocker Lever Support in Engine Systems

The part 4900413 Rocker Lever Support is an integral component in the operation of engine systems, particularly in the valve train mechanism. This support is designed to provide a stable mounting point for the rocker lever, which is essential for the efficient transfer of motion from the camshaft to the valves.

In the valve train, the rocker lever is responsible for amplifying the motion of the camshaft lobe. It does this by converting the rotational motion of the camshaft into the linear motion required to open and close the engine’s valves. The rocker lever support ensures that this conversion is performed with precision and minimal deflection, which is vital for maintaining valve timing and engine performance.

The support is typically mounted on the cylinder head, where it interfaces with other components such as the camshaft, pushrods (in pushrod engines), and the rocker lever itself. In overhead camshaft (OHC) engines, the rocker lever support may be part of the rocker arm assembly, directly interacting with the camshaft lobes.

In engines with hydraulic lifters, the rocker lever support must accommodate the lifter’s operation, which maintains zero valve clearance by adjusting to thermal expansion and wear. The support’s design must allow for the lifter’s movement while ensuring that the rocker lever remains securely in place.

For engines utilizing solid lifters, the rocker lever support must be robust enough to handle the direct transfer of motion from the lifter to the rocker lever without any intervening hydraulic components. This requires a design that can withstand higher stresses and maintain alignment under varying engine loads.

In summary, the part 4900413 Rocker Lever Support plays a significant role in the valve train’s functionality by providing a stable and precise mounting point for the rocker lever. Its design and integration with other engine components are essential for the reliable operation of the valve train and, by extension, the engine’s overall performance.

Conclusion

The 4900413 Rocker Lever Support is a critical component in the operation of Cummins engines, ensuring the efficient and reliable functioning of the valve train system. Its design, compatibility across various engine models, and the benefits it offers in terms of engine performance and longevity make it an essential part for maintaining the high standards of Cummins engines.

-

Xin, Q. (2011). Diesel Engine System Design. Woodhead Publishing Limited.

↩ -

Pacejka, H. B. (2006). Tyre and Vehicle Dynamics. Butterworth-Heinemann.

↩ -

Nunney, M. J. (2007). Light and Heavy Vehicle Technology, Fourth Edition. Butterworth-Heinemann.

↩ -

Bonnick, A., & Newbold, D. (2011). A Practical Approach to Motor Vehicle Engineering and Maintenance, Third Edition. Elsevier Ltd.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.