4975214

Rocker Lever Housing Seal

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Rocker Lever Housing Seal, identified by part number 4975214, is a component manufactured by Cummins, a prominent name in the heavy-duty truck engine industry. This seal plays a role in the functionality and efficiency of heavy-duty truck engines by ensuring the integrity of the rocker lever housing system. Understanding its purpose, operation, and maintenance is important for maintaining engine performance and longevity.

Function and Operation

The Rocker Lever Housing Seal operates by creating a barrier that prevents oil and other contaminants from entering the rocker lever housing. This seal is positioned to maintain the system’s integrity by ensuring that the rocker levers, which are important for valve operation, function within a clean and lubricated environment. Should the seal fail, it could lead to oil leaks, contamination of the valve train components, and ultimately, decreased engine performance and potential damage 1.

Key Features

The design and material characteristics of the Rocker Lever Housing Seal contribute to its performance and durability. Crafted from high-quality materials, this seal is engineered to withstand the high temperatures and pressures present within the engine compartment. Its precise design ensures a tight fit, which is important for effectively sealing the rocker lever housing. These features enhance the seal’s ability to maintain system integrity over extended periods of operation 2.

Benefits

Incorporating the Rocker Lever Housing Seal into heavy-duty truck engines offers several advantages. It contributes to improved engine efficiency by ensuring that the valve train components operate within a clean and properly lubricated environment. Additionally, the seal reduces maintenance needs by minimizing the risk of oil leaks and contamination. Its reliable performance enhances the overall reliability of the engine, making it a valuable component for fleet operators and maintenance professionals 3.

Installation Process

Proper installation of the Rocker Lever Housing Seal is important for ensuring its effectiveness. The process involves several steps, including cleaning the sealing surface to remove any debris or old sealant, inspecting the seal for damage, and carefully positioning it within the rocker lever housing. Using the correct tools and following manufacturer guidelines ensures that the seal is installed correctly, providing optimal performance and longevity.

Common Issues and Troubleshooting

Typical problems associated with the Rocker Lever Housing Seal include oil leaks and seal degradation over time. Diagnostic methods involve visual inspection for signs of oil seepage around the rocker lever housing and assessing the condition of the seal. Potential solutions may include cleaning the sealing surface, reapplying sealant, or replacing the seal if it is damaged or worn.

Maintenance Tips

Regular maintenance practices are key to ensuring the longevity and optimal performance of the Rocker Lever Housing Seal. This includes routine inspections for signs of wear or damage, cleaning the sealing surface during oil changes, and ensuring that the engine operates within recommended temperature and pressure ranges. Adhering to these practices helps prevent issues and extends the service life of the seal.

Replacement Guidelines

Determining when to replace the Rocker Lever Housing Seal involves assessing signs of wear, such as oil leaks or visible damage to the seal. Additionally, following recommended maintenance intervals for seal inspection and replacement, as outlined by the manufacturer, ensures that the engine continues to operate efficiently and reliably. Regular checks and timely replacements are important for maintaining engine performance.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and innovation in the automotive industry. Its extensive product range includes engines and components for heavy-duty trucks, contributing to the efficiency, performance, and durability of these vehicles. Cummins’ commitment to excellence and customer satisfaction underscores its position as a trusted provider in the industry.

Rocker Lever Housing Seal (Part 4975214) Compatibility with Cummins Engines

The Rocker Lever Housing Seal (Part 4975214) by Cummins is designed to fit a variety of engine models, ensuring a proper seal to prevent leaks and maintain optimal engine performance. Here is a detailed breakdown of the compatibility of this part with specific engine models:

ISX12 Series

- ISX12 CM2350 X102

- ISX12 G CM2180 EJ

- ISX12/ISX11.9 CM2250

The ISX12 series engines are known for their robust design and high performance. The Rocker Lever Housing Seal is important for these engines, providing a reliable barrier against oil leaks and contamination.

ISZ13 Series

- ISZ13 CM2150 Z105

The ISZ13 engine is another high-performance model where the Rocker Lever Housing Seal plays a vital role in maintaining the integrity of the rocker lever housing. This seal ensures that the engine operates smoothly by preventing oil from seeping into areas where it shouldn’t.

QSX11.9 Series

- QSX11.9 CM2250 ECF

In the QSX11.9 engine, the Rocker Lever Housing Seal is important for maintaining the engine’s efficiency and longevity. This seal helps in keeping the internal components clean and free from oil contamination.

QSZ13 Series

- QSZ13 CM2150 Z101

- QSZ13 CM2150 Z102

Both the QSZ13 CM2150 Z101 and QSZ13 CM2150 Z102 engines benefit from the Rocker Lever Housing Seal. This part ensures that the engine’s rocker lever housing remains sealed, contributing to the overall reliability and performance of the engine.

Z13 Series

- Z13 Z108G

The Z13 engine series also relies on the Rocker Lever Housing Seal to maintain its operational efficiency. This seal is critical in preventing oil leaks and ensuring that the engine’s internal components are protected from contaminants.

By ensuring that the Rocker Lever Housing Seal is properly fitted, engine owners can maintain the integrity and performance of their engines, avoiding potential issues related to oil leaks and contamination.

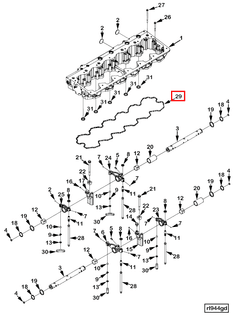

Role of Part 4975214 Rocker Lever Housing Seal in Engine Systems

The part 4975214 Rocker Lever Housing Seal is an important component in maintaining the integrity and efficiency of various engine systems. This seal is specifically designed to fit within the rocker lever housing, ensuring a tight and secure seal that prevents oil leaks and maintains proper lubrication.

Integration with Lever and Rocker Mechanisms

In engine systems, the lever and rocker mechanisms are responsible for transferring motion from the camshaft to the valves. The Rocker Lever Housing Seal plays a significant role here by ensuring that the housing remains sealed. This seal prevents oil from escaping, which could otherwise lead to inadequate lubrication of the rocker arms and levers. Proper lubrication is necessary for the smooth operation of these components, reducing wear and tear and enhancing the overall performance of the engine 4.

Contribution to Overhaul Kits

When it comes to engine overhaul kits, the inclusion of the Rocker Lever Housing Seal is beneficial for several reasons. Overhaul kits are designed to restore engine components to like-new condition. The seal ensures that during the overhaul process, the rocker lever housing is properly sealed, preventing any oil leaks that could compromise the engine’s performance post-overhaul. This contributes to the longevity and reliability of the engine after maintenance.

Importance in Upper Engine Gasket Kits

Upper engine gasket kits are another area where the Rocker Lever Housing Seal is vital. These kits are used to replace worn-out gaskets in the upper portion of the engine, including those around the valve covers and rocker lever housings. The seal works in conjunction with these gaskets to create a comprehensive barrier against oil leaks. This is particularly important in high-performance engines where maintaining optimal lubrication and preventing oil loss is essential for peak performance.

Overall Functionality

In summary, the part 4975214 Rocker Lever Housing Seal is a key component in ensuring the efficient operation of lever and rocker mechanisms, contributing to the effectiveness of overhaul kits, and playing a significant role in upper engine gasket kits. Its proper installation and maintenance are fundamental to the overall health and performance of the engine system.

Conclusion

The Rocker Lever Housing Seal, part number 4975214, is a critical component in the maintenance and efficiency of heavy-duty truck engines. Its role in preventing oil leaks, ensuring proper lubrication, and contributing to the longevity of engine components underscores its importance. Proper installation, regular maintenance, and timely replacement are essential practices for maximizing the performance and reliability of engines equipped with this Cummins part.

-

Hilgers, M. (2022). Transmissions and Drivetrain Design. Springer Vieweg.

↩ -

Fehan, D. R. (2013). Design of Racing and High-Performance Engines 2004-2013. SAE International.

↩ -

Xin, Q. (2011). Diesel Engine System Design. Woodhead Publishing Limited.

↩ -

Lakshminarayanan, P. A., & Nayak, N. S. (2011). Critical Component Wear in Heavy Duty Engines. John Wiley & Sons.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.