This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

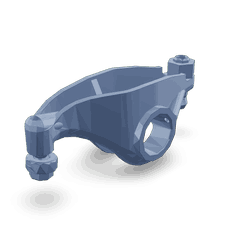

The Cummins 4995631 Rocker Lever is a component designed for use in commercial truck engines. It serves a specific function within the engine’s valve train, contributing to the overall operation and performance of the truck. Understanding its role and significance can provide valuable insights into the complexities of engine mechanics and the importance of each component in ensuring efficient and reliable engine performance.

Basic Concepts of Rocker Levers

A rocker lever, also known as a rocker arm, is a pivotal component in an engine’s valve train. Its primary function is to transfer motion from the camshaft to the valves, allowing them to open and close at precise intervals. This transfer of motion is crucial for the intake and exhaust processes, which are fundamental to the engine’s operation. Rocker levers are commonly used in overhead valve (OHV) engines, where they provide mechanical advantage, allowing for greater valve lift and more efficient engine operation 1.

Purpose of the 4995631 Rocker Lever

This part plays a role in the operation of a truck engine by facilitating the opening and closing of valves in response to camshaft rotation. It interacts with the camshaft through a pushrod and, in turn, actuates the valves. This component ensures that the valves open to the correct extent and at the right time, which is vital for the engine’s combustion process. Its design and material composition are tailored to withstand the high stresses and temperatures encountered in commercial truck engines 2.

Key Features

The 4995631 is characterized by several key features that enhance its performance and durability. It is typically made from high-strength materials to resist wear and fatigue. The design may include features such as hardened contact surfaces to reduce friction and wear, and precise machining to ensure accurate valve actuation. Additionally, the rocker lever may incorporate design elements that facilitate easy installation and maintenance, contributing to its overall effectiveness in the engine system 3.

Benefits

The advantages provided by the 4995631 include improved engine efficiency, durability, and reliability. Its robust construction and precise engineering contribute to consistent valve operation, which is essential for maintaining engine performance over time. The use of high-quality materials and advanced design features ensures that the rocker lever can withstand the demanding conditions of commercial truck operation, leading to longer component life and reduced maintenance requirements 4.

Installation Process

Proper installation of the 4995631 involves several steps to ensure it functions correctly within the engine. This process may require specific tools and additional components, such as pushrods and valve springs. Careful attention to detail during installation is important to maintain the integrity of the valve train and ensure optimal engine performance. Following manufacturer guidelines and procedures is recommended to achieve a successful installation.

Troubleshooting Common Issues

Common problems associated with the 4995631 may include wear and tear or malfunctions due to improper installation or engine conditions. Troubleshooting steps may involve inspecting the rocker lever for signs of damage or wear, checking the clearance between the rocker lever and camshaft, and ensuring that all components in the valve train are properly aligned and adjusted. Addressing these issues promptly can help maintain engine performance and prevent further damage.

Maintenance Tips

Regular maintenance practices are important to ensure the longevity and optimal performance of the 4995631. This may include periodic inspection for wear or damage, cleaning to remove contaminants that could affect performance, and lubrication to reduce friction and wear. Following the manufacturer’s recommended maintenance schedule and procedures can help prevent issues and ensure the rocker lever continues to operate efficiently.

Compatibility of Rocker Lever Part 4995631 with Cummins Engines

The Rocker Lever part 4995631, manufactured by Cummins, is designed to fit a variety of Cummins engines. This part is integral to the valve train mechanism, ensuring the proper opening and closing of engine valves. Below is a detailed breakdown of the engines with which this rocker lever is compatible:

ISC Series Engines

- ISC CM2150

- ISC8.3 CM2250

These engines are part of the ISC series, which are known for their robust design and reliability in various applications.

ISL Series Engines

- ISL CM2150

- ISL9 CM2150 SN

- ISL9 CM2250

- ISL9.5 CM2880 L138

The ISL series engines are recognized for their high performance and efficiency, making them suitable for heavy-duty applications.

QSC/QSL Series Engines

- QSC9 CM2250/QSL9 CM2250

- QSL8.9 CM2150 L141

- QSL9 CM2250

- QSL9 CM2350 L102

- QSL9 CM850 (CM2850)

The QSC/QSL series engines are designed for both on-highway and off-highway applications, providing versatility and durability.

This rocker lever part is engineered to ensure seamless integration with the valve train systems of these engines, facilitating smooth engine operation and longevity.

Role of Part 4995631 Rocker Lever in Engine Systems

The part 4995631 rocker lever is an essential component in the operation of the engine’s valve train system. It works in conjunction with several other components to ensure the precise and efficient opening and closing of the engine’s valves.

Interaction with the Rocker Lever Assembly

The rocker lever, identified by part number 4995631, is a key element within the rocker lever assembly. This assembly typically includes the rocker lever itself, along with pivot points, fulcrums, and sometimes integrated dampening systems. The rocker lever transfers motion from the camshaft to the valves. As the camshaft lobe rises, it pushes against one end of the rocker lever, which then pivots around its fulcrum. This pivoting action causes the opposite end of the rocker lever to depress the valve stem, thereby opening the valve.

Coordination with Camshaft and Valves

In coordination with the camshaft, the rocker lever ensures that the valves open at the correct times in the engine’s operating cycle. The camshaft, with its precisely machined lobes, dictates the timing and duration of valve events. The rocker lever amplifies the motion initiated by the camshaft, providing the necessary force to open the valves against the spring pressure that keeps them closed.

Integration with Valve Springs and Keepers

Valve springs play a significant role in the valve train system by keeping the valves seated when they are not being actuated. The rocker lever must overcome the resistance of these springs to open the valves. Valve keepers secure the valve springs in place, ensuring they remain centered on the valve stem. The efficiency of the rocker lever in this system directly impacts the engine’s performance and longevity.

Influence on Engine Performance

The effectiveness of the rocker lever in transferring motion from the camshaft to the valves influences several aspects of engine performance, including power output, fuel efficiency, and emissions. A well-functioning rocker lever ensures that valves open and close with precision, minimizing the risk of valve float at high engine speeds and ensuring optimal air-fuel mixture intake and exhaust gas expulsion.

Conclusion

In summary, the part 4995631 rocker lever is integral to the valve train’s operation, working seamlessly with the rocker lever assembly, camshaft, valves, and valve springs to maintain the engine’s operational efficiency and performance.

-

Hilgers, Michael. Electrical Systems and Mechatronics, Second Edition. Springer Vieweg, 2023.

↩ -

Bennett, Sean, and Ian Andrew Norman. Heavy Duty Truck Systems, Fifth Edition. Delmar Cengage Learning, 2011.

↩ -

Lakshminarayanan, P. A., and Avinash Kumar Agarwal. Design and Development of Heavy Duty Diesel Engines: A Handbook. Springer, 2019.

↩ -

Arora, Shashank, Alireza Tashakori Abkenar, and Shantha Gamini Jayasi. Heavyduty Electric Vehicles: From Concept to Reality. Elsevier, 2021.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.