This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

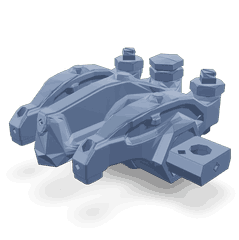

The Cummins 4999540 Rocker Lever is a component designed for use in commercial truck engines. It serves a specific function within the engine’s valve train, contributing to the overall performance and efficiency of the truck. Understanding its purpose and significance is important for maintaining and optimizing the operation of commercial trucks.

Basic Concepts of Rocker Levers

A rocker lever, also known as a rocker arm, is a mechanical component used in internal combustion engines. It acts as a lever that transfers motion from the camshaft to the valves. When the camshaft rotates, it pushes on one end of the rocker lever, which then rocks on its pivot point and opens the valve at the other end. This mechanism allows for precise control over the timing and duration of valve opening, which is critical for engine operation 1.

Purpose of the 4999540 Rocker Lever

The 4999540 Rocker Lever plays a role in the operation of a truck engine by facilitating the transfer of motion from the camshaft to the valves. It ensures that the valves open and close at the correct times in the engine cycle, which is necessary for efficient combustion and engine performance. The rocker lever interacts with other components such as the camshaft, pushrods, and valve springs to achieve this function.

Key Features

The 4999540 Rocker Lever is constructed from high-quality materials to ensure durability and reliability. Its design includes specific features such as a hardened contact surface to resist wear from the camshaft and valve, and precise machining to ensure smooth operation. The lever may also incorporate design elements that reduce noise and vibration, contributing to a quieter and more efficient engine operation.

Benefits

The advantages provided by the 4999540 Rocker Lever include improved engine performance due to its precise control over valve timing. Its durable construction contributes to the longevity of the engine components, and its reliable operation ensures consistent engine performance over time. These factors combined make the rocker lever a valuable component in the engine system.

Installation Process

Proper installation of the 4999540 Rocker Lever involves several steps. It begins with ensuring the engine is in the correct position for valve adjustment. The old rocker lever, if being replaced, is removed, and the new one is positioned in place. Torque specifications must be followed when tightening the rocker lever to its pivot point to ensure proper operation. Tools required may include a torque wrench and socket set.

Common Issues and Troubleshooting

Common problems associated with the 4999540 Rocker Lever can include wear on the contact surfaces, which may lead to improper valve operation. Troubleshooting steps involve inspecting the lever for signs of wear or damage, and ensuring that it is properly installed and adjusted. Solutions may range from re-torquing the lever to replacement if wear is significant.

Maintenance Tips

Regular maintenance practices for the 4999540 Rocker Lever include periodic inspection for wear and proper operation. Lubrication of the pivot point and contact surfaces can help reduce friction and wear. Following the manufacturer’s recommended maintenance schedule will help ensure the longevity and optimal performance of the rocker lever.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history dating back to 1919, Cummins has established a reputation for quality and reliability in the commercial truck industry. The company’s commitment to innovation and customer satisfaction has made it a preferred choice for engine components, including the 4999540 Rocker Lever 2.

Role of Part 4999540 Rocker Lever in Engine Systems

The 4999540 Rocker Lever is an essential component in the operation of various engine systems. It works in conjunction with several other components to ensure the efficient and smooth functioning of the engine.

Interaction with the Valve Train

The Rocker Lever, specifically part 4999540, is a key element in the valve train mechanism. It is responsible for transferring the motion from the camshaft to the valves. When the camshaft lobe rises, it pushes against the rocker lever, which then amplifies this motion and transfers it to the valve. This action opens the valve, allowing air and fuel into the combustion chamber or expelling exhaust gases.

Coordination with Pushrods

In overhead valve (OHV) engines, the Rocker Lever is typically connected to pushrods. The pushrods transmit the motion from the camshaft, located in the engine block, to the rocker lever situated in the cylinder head. The precise movement of the pushrod ensures that the rocker lever operates at the correct timing, which is vital for the engine’s performance and efficiency.

Integration with Valve Springs

Valve springs play a significant role in the valve train system by ensuring that the valves close properly after being opened by the rocker lever. The interaction between the rocker lever and valve springs must be harmonious to prevent issues such as valve float at high engine speeds, which can lead to decreased performance and potential engine damage.

Role in Overhead Cam (OHC) Engines

In overhead cam (OHC) engines, the rocker lever might not be as prominently featured, but it still plays a role in certain designs. Here, the camshaft is located directly above the valves, and the rocker lever may be used to provide additional mechanical advantage or to adjust valve clearance. This setup allows for more precise control over valve operation, contributing to better engine performance and fuel efficiency.

Contribution to Engine Timing

The timing of the rocker lever’s operation is integral to the overall engine timing. It must work in sync with the camshaft and crankshaft to ensure that the valves open and close at the correct moments in the engine cycle. This synchronization is essential for optimal combustion and power delivery.

Impact on Valve Lash Adjustment

Proper valve lash, or the clearance between the camshaft lobe and the rocker lever, is critical for the engine’s operation. The rocker lever allows for easy adjustment of this clearance, ensuring that the valves operate within the specified parameters. Incorrect valve lash can lead to poor engine performance, increased wear, and potential damage.

Conclusion

In summary, the 4999540 Rocker Lever is a vital component that interacts with various elements of the engine system to ensure efficient and reliable operation. Its role in the valve train, coordination with pushrods, integration with valve springs, and contribution to engine timing and valve lash adjustment underscores its importance in engine functionality.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.