This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

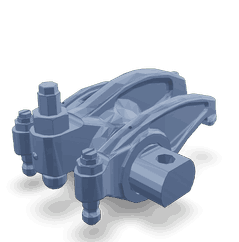

The 4999541 Rocker Lever Assembly is a component designed for use in heavy-duty truck engines. It plays a role in the engine’s valve train system, facilitating the transfer of motion from the camshaft to the valves. Cummins Inc., a well-established manufacturer in the automotive industry, produces this assembly. Known for its extensive range of diesel engines and related components, Cummins has built a reputation for quality and reliability 1.

Basic Concepts of Rocker Lever Assembly

Rocker lever assemblies are integral to the valve train system of an engine. They operate on the principle of mechanical leverage, amplifying the motion generated by the camshaft to open and close the engine’s valves at precise intervals. This system ensures that the air-fuel mixture enters the combustion chamber at the correct time, and exhaust gases are expelled efficiently 2.

Purpose and Function

This Cummins part is designed to transfer motion from the camshaft to the valves in a truck engine. It achieves this by converting the rotational motion of the camshaft into the linear motion required to operate the valves. This transfer of motion is crucial for the engine’s operation, as it directly influences the timing and efficiency of the combustion process 3.

Key Features

The 4999541 is constructed with precision engineering in mind. It incorporates materials and design elements that enhance its durability and performance. The assembly is crafted from high-quality materials to withstand the rigors of heavy-duty truck operation. Its design includes specific engineering specifications that ensure compatibility and optimal function within the engine system 4.

Benefits

The 4999541 Rocker Lever Assembly offers several advantages. It contributes to improved engine performance by ensuring precise valve operation. Its durable construction enhances the reliability of the engine, reducing the likelihood of failures. Additionally, the assembly’s design promotes efficient engine operation, which can lead to better fuel economy and reduced emissions 1.

Installation and Compatibility

Proper installation of this part is key to ensuring its effective operation. It is important to follow manufacturer guidelines to achieve the best results. Compatibility with specific engine models should be verified to ensure optimal performance and longevity of the assembly within the engine system 2.

Maintenance and Troubleshooting

Routine maintenance of the 4999541 Rocker Lever Assembly is recommended to maintain its performance and longevity. This includes regular inspections for wear and proper lubrication. Common issues may include noise from the valve train or decreased engine performance, which can often be traced back to the rocker lever assembly. Diagnostic procedures and troubleshooting tips can help identify and resolve these issues efficiently 3.

Performance Enhancements

For those looking to enhance engine performance, modifications or upgrades to the 4999541 Rocker Lever Assembly may be considered. These can include adjustments to the leverage ratio or the use of materials that offer greater strength or reduced weight. Such enhancements can contribute to improved engine efficiency and power output 4.

Cummins Corporation

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions. With a history spanning over a century, Cummins has established itself as a trusted name in the automotive industry. Its product range includes diesel and natural gas engines, as well as related technologies. Cummins is renowned for its commitment to quality, innovation, and customer satisfaction 1.

Compatibility of the 4999541 Rocker Lever Assembly

The 4999541 is designed to fit seamlessly with several engine models, ensuring optimal performance and reliability. This part is engineered to work with the following engines:

QSNT14 CM876 N102

The Rocker Lever Assembly 4999541 is compatible with the QSNT14 CM876 N102 engine. This compatibility ensures that the assembly will integrate smoothly with the engine’s design, providing the necessary support and functionality for the valve train system. The precision engineering of this part guarantees that it will meet the stringent demands of the QSNT14 CM876 N102 engine, enhancing its operational efficiency and longevity 2.

Grouped Compatibility

In addition to the QSNT14 CM876 N102 engine, the Rocker Lever Assembly 4999541 is also suitable for other engines within the same family or series. This grouping is based on shared design characteristics and engineering specifications that ensure the assembly’s compatibility across multiple engine models. By using this part, technicians and engineers can maintain consistency and reliability across different engine types, simplifying maintenance and repair processes 3.

Component Usage of the 4999541 Rocker Lever Assembly

The 4999541 is an integral component in the operation of several engine systems, facilitating the conversion of the linear motion of the pushrod into the rotational motion required by the valve. This assembly interfaces directly with the camshaft and the valve train, ensuring precise and efficient valve operation 4.

Valve Train Mechanism

In the valve train mechanism, the Rocker Lever Assembly is positioned between the pushrod and the valve stem. When the camshaft lobe rises, it pushes the pushrod, which in turn applies force to the rocker lever. The rocker lever then pivots on its fulcrum, transferring this force to the valve stem, causing the valve to open. This process allows for the intake of air-fuel mixture and the expulsion of exhaust gases, essential for the engine’s combustion cycle 1.

Camshaft Interaction

The Rocker Lever Assembly engages with the camshaft through the use of a cam follower or roller. As the camshaft rotates, the lobes push against the follower, initiating the rocker’s pivot. This interaction must be smooth and consistent to ensure the valve opens and closes at the correct times, maintaining engine performance and efficiency 2.

Pushrod Connection

The connection between the Rocker Lever Assembly and the pushrod is designed to be robust and durable. The pushrod transmits the motion from the camshaft to the rocker lever. Proper alignment and minimal clearance are essential to prevent any loss of motion or efficiency, ensuring that the valve operation is precise 3.

Valve Stem Engagement

At the other end of the rocker lever, the assembly engages with the valve stem. This engagement point is critical for transferring the motion from the rocker to the valve. The design ensures that the force is transmitted effectively, allowing the valve to open and close with the required force and speed 4.

Overall System Integration

The Rocker Lever Assembly is a key element in the overall integration of the engine’s valve train system. It works in concert with the camshaft, pushrods, and valve springs to ensure that the valves operate in sync with the engine’s combustion cycles. The assembly’s design and material must withstand the high stresses and temperatures within the engine compartment, contributing to the durability and reliability of the engine system 1.

Conclusion

The 4999541 Rocker Lever Assembly by Cummins is a critical component in the valve train system of heavy-duty truck engines. Its precise engineering, compatibility with various engine models, and the benefits it offers in terms of engine performance and reliability make it a valuable part for maintaining and enhancing engine efficiency. Proper installation, maintenance, and understanding of its function within the engine system are essential for maximizing its benefits and ensuring the longevity of the engine 1234.

-

Randall, Martynn. Haynes Manual on Diesel Engines. Haynes Publishing, 2015.

↩ ↩ ↩ ↩ ↩ ↩ -

Duffy, Owen C and Wright, Gus. Fundamentals of Medium-Heavy Duty Commercial Vehicle Systems. Jones Bartlett Learning, 2016.

↩ ↩ ↩ ↩ ↩ -

Hilgers, Michael. Alternative Powertrains and Extensions to the Conventional Powertrain. Springer Nature, 2023.

↩ ↩ ↩ ↩ ↩ -

Reif, Konrad Ed. Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg, 2014.

↩ ↩ ↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.