4999837

Rocker Lever Adjusting Screw

Cummins®

AVAILABLE

2 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 4999837 Rocker Lever Adjusting Screw is a component manufactured by Cummins, a well-established name in the heavy-duty truck industry. This screw is integral to the operation of heavy-duty truck engines, particularly in the context of valve train mechanisms. Understanding its function and significance can provide valuable insights into engine maintenance and performance optimization.

Basic Concepts of Rocker Lever Adjusting Screws

A Rocker Lever Adjusting Screw is a mechanical component used within the valve train of an engine. Its primary function is to facilitate the adjustment of valve clearance, which is the gap between the valve and the camshaft. Proper valve clearance is essential for the efficient operation of the engine, as it ensures that the valves open and close at the correct times and with the appropriate force. This, in turn, contributes to the engine’s overall performance, fuel efficiency, and longevity 1.

Purpose of the 4999837 Rocker Lever Adjusting Screw

The 4999837 Rocker Lever Adjusting Screw plays a specific role in the operation of a truck engine by allowing for precise adjustments of valve clearance. This adjustment is necessary to accommodate wear and tear on engine components over time, ensuring that the valves continue to operate efficiently. By enabling fine-tuned adjustments, this screw helps maintain optimal engine performance and reduces the risk of valve-related issues 2.

Key Features

The 4999837 Rocker Lever Adjusting Screw is designed with several characteristics that enhance its performance and durability. It is crafted from high-quality materials to withstand the demanding conditions within a heavy-duty truck engine. The screw’s design allows for easy and precise adjustments, contributing to its effectiveness in maintaining proper valve clearance. Additionally, its construction ensures resistance to wear and corrosion, prolonging its service life 3.

Benefits

Utilizing the 4999837 Rocker Lever Adjusting Screw offers several advantages. It contributes to improved engine efficiency by ensuring that valves operate within the optimal clearance range. This can lead to better fuel economy and reduced emissions. Furthermore, the screw’s design and material quality result in reduced maintenance needs, as it is less prone to wear and failure. Enhanced reliability is another benefit, as proper valve clearance adjustments help prevent engine damage and ensure consistent performance 4.

Installation Process

Installing the 4999837 Rocker Lever Adjusting Screw requires careful attention to detail. The process involves loosening the locknut, turning the screw to achieve the desired valve clearance, and then securing the locknut in place. It is recommended to use a torque wrench to ensure that the locknut is tightened to the manufacturer’s specified torque settings. Following the manufacturer’s guidelines and using the appropriate tools will help ensure a successful installation 5.

Troubleshooting Common Issues

Common problems associated with Rocker Lever Adjusting Screws can include improper valve clearance, which may lead to engine performance issues. To address these problems, it is important to regularly inspect the screw and its associated components for signs of wear or damage. If adjustments are needed, following the correct procedure for making these changes can help resolve issues and restore optimal engine operation .

Maintenance Tips

Regular maintenance of the 4999837 Rocker Lever Adjusting Screw is key to ensuring optimal performance and longevity. This includes periodic inspections to check for wear, corrosion, or any signs of damage. It is also important to ensure that the screw is properly tightened and that valve clearances are within the manufacturer’s specifications. Adhering to recommended inspection intervals and addressing any issues promptly can help maintain the screw’s effectiveness and contribute to the overall reliability of the engine .

Compatibility of Rocker Lever Adjusting Screw (Part 4999837) with Cummins Engines

The Rocker Lever Adjusting Screw, part number 4999837, manufactured by Cummins, is a critical component in maintaining the operational integrity of various engine models. This screw is integral to the engine’s valve train system, ensuring precise valve clearance and performance.

ISX12 Series

- ISX12 CM2350 X102

- ISX12 G CM2180 EJ

- ISX12/ISX11.9 CM2250

The ISX12 series engines benefit from the Rocker Lever Adjusting Screw in maintaining the correct valve clearance. This is crucial for the high-performance demands of these engines, ensuring smooth operation and longevity.

ISZ13 Series

- ISZ13 CM2150 Z105

The ISZ13 engine, equipped with the Rocker Lever Adjusting Screw, relies on this component to fine-tune the valve clearance, which is essential for optimal engine performance and efficiency.

QSX11.9 Series

- QSX11.9 CM2250 ECF

In the QSX11.9 engine, the Rocker Lever Adjusting Screw plays a pivotal role in adjusting the rocker arm clearance. This adjustment is vital for the engine’s reliability and performance, especially under varying load conditions.

QSZ13 Series

- QSZ13 CM2150 Z101

- QSZ13 CM2150 Z102

Both QSZ13 engines utilize the Rocker Lever Adjusting Screw to maintain precise valve clearance. This ensures that the engine operates efficiently and reliably across different operational scenarios.

Z13 Series

- Z13 Z108G

The Z13 engine also incorporates the Rocker Lever Adjusting Screw to manage valve clearance. This component is essential for the engine’s performance and durability, ensuring that the valve train operates smoothly and without excessive wear.

Role of Part 4999837 Rocker Lever Adjusting Screw in Engine Systems

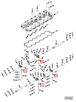

The part 4999837 Rocker Lever Adjusting Screw is an integral component in the operation of the rocker lever and rocker top level assembly lever within engine systems. This screw is specifically designed to fine-tune the clearance between the rocker lever and the components it interacts with, such as the camshaft and valve stem.

In the context of the rocker lever, the adjusting screw ensures that the lever maintains the correct gap, which is essential for the efficient transfer of motion from the camshaft to the valve. This precise adjustment allows for optimal valve timing, which directly influences the engine’s performance, fuel efficiency, and emissions.

When considering the rocker top level assembly lever, the 4999837 screw plays a significant role in maintaining the structural integrity and operational efficiency of the assembly. By allowing for minor adjustments, it helps in compensating for wear and tear, ensuring that the lever continues to function smoothly over the engine’s lifespan.

Overall, the 4999837 Rocker Lever Adjusting Screw is a key element in the meticulous balancing act that is engine valve operation, contributing to the seamless interaction between the lever, rocker, and other interconnected components.

Conclusion

The 4999837 Rocker Lever Adjusting Screw is a vital component in the maintenance and optimization of heavy-duty truck engines. Its role in ensuring precise valve clearance is crucial for engine performance, fuel efficiency, and longevity. Regular maintenance and proper installation are essential to maximize the benefits of this Cummins part.

-

Barton, D. C., & Fieldhouse, J. D. (2009). Automotive Chassis Engineering Powertrain Chassis System and Vehicle Body. Elsevier.

↩ -

Brach, R. M. (2023). SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety. SAE Books.

↩ -

Khajepour, A. (2023). Synthesis Lectures on Advances in Automotive Technology. Springer.

↩ -

Bennett, S. (2012). Modern Diesel Technology Light Duty Diesels. Cengage Learning.

↩ -

Cummins Inc. (n.d.). ISX15 CM2250 Service Manual (4022250).

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.