This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

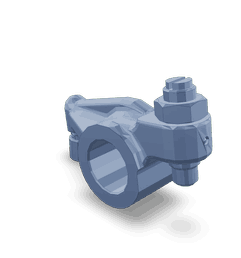

The Cummins 5282812 Rocker Lever is a component designed for use in heavy-duty truck engines. It serves a specific function within the engine’s valve train, contributing to the overall operation and performance of the vehicle. Understanding its role and significance can provide insight into the complexities of engine mechanics and the importance of each component in ensuring efficient and reliable engine function.

Basic Concepts of Rocker Levers

A rocker lever, also known as a rocker arm, is a pivotal component in an engine’s valve train mechanism. It acts as a lever that converts the motion of the camshaft into the opening and closing of the engine’s valves. By providing a mechanical advantage, the rocker lever amplifies the camshaft’s motion, allowing for precise control over valve operation. This mechanism ensures that the valves open and close at the correct times and with the appropriate force, which is crucial for the engine’s combustion process 1.

Purpose of the 5282812 Rocker Lever

The 5282812 Rocker Lever is specifically engineered for Cummins engines, where it plays a role in the valve train by transferring motion from the camshaft to the valves. This transfer ensures that the valves open and close in sync with the engine’s operation, facilitating the intake of air and fuel and the exhaust of combustion gases. Its design allows for efficient and reliable valve actuation, contributing to the engine’s overall performance and durability 2.

Key Features

The 5282812 Rocker Lever is characterized by its robust design and high-quality materials, which contribute to its durability and precision engineering. It is crafted to withstand the high stresses and temperatures within the engine environment. Unique design elements, such as its geometry and surface treatments, enhance its performance by reducing friction and wear, ensuring smooth operation over the engine’s lifespan 3.

Benefits

The advantages provided by the 5282812 Rocker Lever include improved engine efficiency and reliability. Its precise engineering and durable construction contribute to consistent valve operation, which is vital for maintaining engine performance. Additionally, the enhanced mechanical advantage offered by the rocker lever can lead to potential performance improvements, making it a valuable component in the engine’s design.

Installation and Compatibility

Proper installation of the 5282812 Rocker Lever is crucial for ensuring its effective function within the engine. Guidelines for installation should be followed to maintain the integrity of the valve train mechanism. Compatibility with specific engine models ensures that the rocker lever meets the design and operational requirements of the engine, contributing to its overall performance and reliability.

Troubleshooting and Maintenance

Common issues associated with rocker levers include wear, improper adjustment, and failure due to material fatigue. Regular maintenance and inspection can help identify these issues early, allowing for timely repairs or replacements. Maintenance tips for the 5282812 Rocker Lever include checking for proper clearances, ensuring smooth operation, and inspecting for signs of wear or damage. Recommended inspection intervals should be adhered to for optimal performance and longevity.

Performance Enhancements

Modifications or upgrades to the rocker lever system can impact engine performance. Aftermarket options may offer improvements in material strength, reduced weight, or enhanced design features that can contribute to increased engine efficiency or power output. Careful consideration should be given to the compatibility and quality of aftermarket components to ensure they meet the engine’s operational requirements.

Cummins Corporation

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and related technologies. With a strong reputation in the automotive industry, Cummins is committed to innovation and quality in manufacturing engine components. The company’s dedication to advancing technology and meeting customer needs underscores its position as a leader in the field of engine manufacturing.

Cummins Rocker Lever 5282812 Compatibility

The Cummins Rocker Lever part number 5282812 is designed to fit seamlessly within a variety of Cummins engines. This part is engineered to ensure smooth and reliable operation of the engine’s valve train system.

QSB3.3 Engines

The QSB3.3 engines, known for their robust performance and versatility, are compatible with the Rocker Lever 5282812. This part is essential for maintaining the precise valve timing and operation necessary for the efficient functioning of these engines.

CM2250 Engines

The CM2250 engines also benefit from the Rocker Lever 5282812. This component is specifically designed to fit the unique design and specifications of the CM2250, ensuring optimal performance and longevity.

EC Engines

The EC engines, which are part of the Cummins engine family, are another series where the Rocker Lever 5282812 is a perfect fit. This part is engineered to meet the stringent requirements of the EC engines, providing reliable and consistent performance.

Grouping of Engines

The QSB3.3 and CM2250 engines share similar design principles and operational requirements, making the Rocker Lever 5282812 compatible with both. The EC engines, while distinct in their own right, also benefit from this part due to its universal design features that cater to a range of Cummins engine models.

Conclusion

The Cummins 5282812 Rocker Lever is a critical component in the operation of Cummins engines, ensuring efficient and reliable valve actuation. Its robust design, precise engineering, and compatibility with various Cummins engine models make it an essential part for maintaining engine performance and durability. Regular maintenance and proper installation are key to maximizing the benefits of this component.

-

Advanced Automotive Electricity and Electronics, Michael Klyde and Kirk VanGelder, Jones Bartlett Learning, 2010.

↩ -

Introduction to Engine Valvetrains, Yushu Wang, SAE International, 2007.

↩ -

Fundamentals of Medium-Heavy Duty Commercial Vehicle Systems, Owen C Duffy and Gus Wright, Jones Bartlett Learning, 2016.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.