5374775

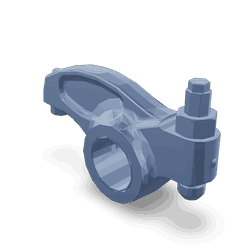

Rocker Lever

Cummins®

AVAILABLE

More than 10 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 5374775 Rocker Arm Lever, manufactured by Cummins, is a critical component for the operation of heavy-duty trucks. Cummins, a prominent name in the automotive industry, is known for its high-quality engine components. This part is designed to enhance the efficiency and reliability of truck engines, significantly contributing to their overall performance 1.

Basic Concepts of Rocker Arm Levers

A rocker arm lever is a mechanical component found in internal combustion engines. Its primary function is to facilitate the movement of engine valves. By converting the motion from the camshaft into a force that opens and closes the valves, the rocker arm lever ensures that the air-fuel mixture enters and exits the combustion chamber at the correct times. This precise timing is essential for the engine’s operation, as it directly affects the engine’s power output and efficiency 2.

Purpose of the 5374775 Rocker Arm Lever

The 5374775 Rocker Arm Lever is specifically designed for use in Cummins engines. It operates by interacting with the camshaft and pushrods to control the opening and closing of the engine’s valves. This lever plays a role in maintaining the correct valve timing, which is vital for the engine’s performance. Its design allows for efficient transfer of motion from the camshaft to the valves, ensuring that the engine operates smoothly and effectively 3.

Key Features

This Cummins part is characterized by its robust design and high-quality materials. It is constructed from durable materials that can withstand the high temperatures and pressures within an engine. The lever’s design includes features that reduce friction and wear, contributing to its longevity and reliable performance. These characteristics are essential for maintaining the efficiency and durability of the engine 4.

Benefits

The use of the 5374775 Rocker Arm Lever in an engine can lead to several advantages. It contributes to improved engine efficiency by ensuring precise valve timing and operation. The lever’s durable construction and design features also enhance the engine’s reliability and longevity, reducing the need for frequent replacements or repairs. This can result in cost savings and increased uptime for heavy-duty trucks.

Installation Process

Installing the 5374775 Rocker Arm Lever requires careful attention to detail and the use of appropriate tools. The process involves removing the old lever, if present, and ensuring that the engine components are clean and free of debris. The new lever should be positioned correctly and secured in place, following the manufacturer’s guidelines. It is important to check for proper alignment and operation before completing the installation.

Common Issues and Troubleshooting

Rocker arm levers, including the 5374775, can encounter issues such as wear, misalignment, or failure due to material fatigue. Diagnosing these problems typically involves inspecting the lever for signs of damage or wear and checking the engine’s performance. Solutions may range from simple adjustments to replacement of the lever. Regular maintenance and inspections can help identify and address issues before they lead to significant engine problems.

Maintenance Tips

To ensure the longevity and optimal performance of the 5374775 Rocker Arm Lever, routine maintenance is recommended. This includes regular inspections for signs of wear or damage, ensuring proper alignment and operation, and keeping the engine clean. Following the manufacturer’s maintenance guidelines can help prevent issues and extend the life of the lever and the engine as a whole.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation in the automotive industry, particularly in the heavy-duty truck sector. The company’s product range includes a variety of engine components and systems, all designed to meet the demanding requirements of commercial and industrial applications. Cummins’ commitment to quality, innovation, and customer satisfaction has made it a preferred choice for engine components in the heavy-duty truck industry.

Cummins Rocker Arm Lever 5374775 Compatibility

The Cummins Rocker Arm Lever part number 5374775 is designed to fit seamlessly within the engine architecture of the QSK78 CM500 series. This part is integral to the engine’s valve train system, ensuring precise control over the opening and closing of the engine’s valves.

In the QSK78 CM500 engines, the Rocker Arm Lever 5374775 interfaces with the camshaft and valve train components to facilitate smooth and efficient engine operation. Its design and engineering ensure that it can withstand the high stresses and operational demands of these powerful engines.

The compatibility of this part extends to other Cummins engines within the same series, ensuring that the Rocker Arm Lever 5374775 can be used across multiple models without modification. This standardization simplifies maintenance and repair processes, providing a reliable and consistent performance across the engine range.

Understanding the Integration of Part 5374775 Rocker Arm Lever in Engine Systems

The part 5374775 Rocker Arm Lever is a critical component in the operation of various engine systems, facilitating the conversion of linear piston motion into rotational motion for the valves. This conversion is vital for the intake and exhaust processes within the engine.

Interaction with the Valve Train

The Rocker Arm Lever, specifically part 5374775, is mounted on a pivot point known as the rocker shaft. It interacts directly with the valve stem on one end and the pushrod or camshaft on the other. When the camshaft lobe rises, it pushes against the rocker arm lever, which then amplifies this motion to open the valve. This mechanism ensures that the valve opens sufficiently to allow the necessary air-fuel mixture into the combustion chamber during the intake stroke and expels exhaust gases during the exhaust stroke.

Coordination with Pushrods and Camshafts

In overhead valve (OHV) engines, the Rocker Arm Lever works in conjunction with pushrods. The pushrod transmits the motion from the camshaft, located in the engine block, to the rocker arm lever situated in the cylinder head. The precise movement of the rocker arm lever is dependent on the design and profile of the camshaft, which dictates the timing and duration of valve events.

In overhead camshaft (OHC) engines, the rocker arm lever may interact directly with the camshaft without the need for pushrods. This direct interaction can provide more accurate valve timing and potentially higher engine performance due to reduced mechanical losses.

Role in Valve Clearance Adjustment

The Rocker Arm Lever also plays a role in valve clearance adjustment. In many engine designs, the lever allows for the adjustment of valve lash, which is the clearance between the camshaft lobe and the rocker arm lever. Proper valve lash is essential for optimal engine performance and longevity, preventing issues such as valve float at high RPMs or excessive wear due to tight clearances.

Contribution to Engine Efficiency

By efficiently transferring motion from the camshaft to the valves, the Rocker Arm Lever contributes to the overall efficiency of the engine. Its design and material properties are engineered to withstand the high cycles of operation and the forces exerted during engine runtime. The lever’s ability to maintain precise valve timing and lift directly impacts the engine’s power output, fuel efficiency, and emissions.

Conclusion

In summary, the 5374775 Rocker Arm Lever is a fundamental component in the valve train system, ensuring the proper operation of the engine by facilitating the precise and timely opening and closing of the valves. Its integration with other components like the camshaft, pushrods, and valve stems is essential for the engine’s performance and durability.

-

Minaker, Bruce P. Fundamentals of Vehicle Dynamics and Modelling. John Wiley & Sons, 2019.

↩ -

Dixon, John. Modern Diesel Technology: Heating, Ventilation, Air Conditioning, Refrigeration, 2nd Edition. Cengage Learning, 2014.

↩ -

Dixon, John. Modern Diesel Technology Preventive Maintenance and Inspection. Delmar Cengage Learning, 2010.

↩ -

Zhao, Hua. Advanced Direct Injection Combustion Engine Technologies and Development Volume 2 Diesel Engines. CRC Press, 2010.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.