5484231

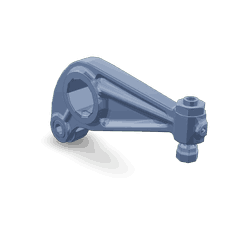

Rocker Lever

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 5484231 Rocker Lever is a component used in heavy-duty truck engines, specifically within the valve train mechanism. It is designed to facilitate the transfer of motion from the camshaft to the valves, ensuring precise and efficient operation of the engine’s intake and exhaust functions.

Basic Concepts of Rocker Levers

A rocker lever, also known as a rocker arm, is a pivotal component in an engine’s valve train. It operates by converting the rotational motion of the camshaft into linear motion to open and close the engine’s valves. The rocker lever interacts with other components such as pushrods, which transmit motion from the camshaft to the rocker lever, and the valves, which it directly actuates 1.

Purpose of the 5484231 Rocker Lever

The Cummins 5484231 Rocker Lever is integral to the operation of a truck engine. It plays a role in transferring motion from the camshaft to the valves, ensuring that the valves open and close at the correct times and with the appropriate force. This precise timing and force are essential for the engine’s performance, fuel efficiency, and overall reliability 2.

Key Features

The Cummins 5484231 Rocker Lever is characterized by several key features that enhance its performance and durability. It is typically made from high-strength materials to withstand the high stresses and temperatures within an engine. Design elements such as precise machining and hardened contact surfaces contribute to its reliability and longevity. Additionally, the rocker lever may feature unique characteristics such as adjustable geometry to accommodate different valve spring pressures and engine configurations.

Benefits

The Cummins 5484231 Rocker Lever offers several advantages. It contributes to improved engine efficiency by ensuring that valves operate with minimal friction and maximum precision. Its robust construction enhances the reliability of the engine, reducing the likelihood of failures. Furthermore, the precise operation of the rocker lever can lead to potential enhancements in engine performance, including smoother operation and increased power output 3.

Installation and Compatibility

Proper installation of the Cummins 5484231 Rocker Lever is crucial for ensuring optimal engine performance. It should be installed according to the manufacturer’s guidelines, which may include specific torque specifications and alignment procedures. Compatibility with various engine models and configurations should be verified to ensure that the rocker lever is suitable for the intended application.

Troubleshooting and Maintenance

Common issues associated with rocker levers include wear, improper adjustment, and failure due to material fatigue. Diagnostic tips for identifying problems with the Cummins 5484231 Rocker Lever include checking for unusual engine noises, observing valve operation, and inspecting the rocker lever for signs of wear or damage. Regular maintenance practices, such as periodic inspection and adjustment, can help ensure the optimal performance and longevity of the rocker lever.

Performance Enhancements

Modifications or upgrades to the Cummins 5484231 Rocker Lever can potentially enhance engine performance. Aftermarket options may include upgraded materials for increased durability, adjustable components for fine-tuning valve operation, or specialized designs for high-performance applications. These enhancements should be carefully considered and installed according to the manufacturer’s recommendations to avoid compromising engine reliability.

Compatibility of Rocker Lever Part 5484231 with Cummins Engines

The Rocker Lever part 5484231, manufactured by Cummins, is designed to fit a variety of their engine models. This part is integral to the engine’s valve train system, ensuring proper valve operation and overall engine performance. Here is a detailed overview of its compatibility with the listed engines:

ISX Series Engines

- ISX CM570

- ISX CM870

- ISX CM871

The Rocker Lever part 5484231 is compatible with the ISX series engines, including the ISX CM570, ISX CM870, and ISX CM871. These engines are known for their robust performance and reliability, often used in heavy-duty applications.

ISX15 Series Engines

- ISX15 CM2250

- ISX15 CM2250 SN

- ISX15 CM2350 X101

The ISX15 series engines, such as the ISX15 CM2250, ISX15 CM2250 SN, and ISX15 CM2350 X101, also utilize the Rocker Lever part 5484231. These engines are part of the next generation of ISX engines, offering improved efficiency and power.

QSX15 Series Engines

- QSX15 CM2250

- QSX15 CM2250 ECF

- QSX15 CM2350 X105

The QSX15 series engines, including the QSX15 CM2250, QSX15 CM2250 ECF, and QSX15 CM2350 X105, are compatible with the Rocker Lever part 5484231. These engines are designed for applications requiring high torque and durability.

X15 Series Engines

- X15 CM2350 X116B

- X15 CM2350 X123B

- X15 CM2450 X134B

The X15 series engines, such as the X15 CM2350 X116B, X15 CM2350 X123B, and X15 CM2450 X134B, also fit the Rocker Lever part 5484231. These engines are part of Cummins’ latest lineup, offering advanced technology and performance enhancements.

Each of these engines relies on the Rocker Lever part 5484231 to maintain the precise operation of the valve train, ensuring optimal engine performance and longevity.

Role of Part 5484231 Rocker Lever in Engine Systems

The part 5484231 Rocker Lever is an integral component within the engine’s valve train system, facilitating the conversion of the camshaft’s rotational motion into the linear motion required to open and close the engine’s valves. This conversion is essential for the intake and exhaust processes, which are fundamental to the engine’s operation.

Interaction with the Valve Train

The Rocker Lever, specifically part 5484231, is mounted on a pivot point known as the rocker shaft. It engages with the camshaft via a cam lobe at one end and is connected to the valve stem at the other end through a pushrod in overhead valve (OHV) engines or directly in overhead cam (OHC) engines. This setup allows the Rocker Lever to amplify the camshaft’s motion, ensuring precise and efficient valve operation.

Assembly Integration

Within the Rocker Lever Top Level Assembly, part 5484231 plays a key role. This assembly typically includes the rocker lever itself, along with adjusters, springs, and other components necessary for maintaining proper valve clearance and operation. The Rocker Lever’s design and material are selected to withstand the high stresses and temperatures encountered in the engine environment, ensuring durability and reliability.

Functional Dynamics

The dynamics of the Rocker Lever’s operation are influenced by its geometry and the characteristics of the cam profile it engages with. As the camshaft rotates, the cam lobe pushes against the Rocker Lever, causing it to pivot and push down on the valve stem. This action opens the valve, allowing air and fuel into the combustion chamber or expelling exhaust gases. The return spring then closes the valve, readying the engine for the next cycle.

Maintenance and Adjustment

Regular maintenance of the Rocker Lever and its associated components is vital for engine performance. Adjustments may be necessary to account for wear and ensure optimal valve timing and lift. This maintenance often involves checking and adjusting the valve clearance, which is the gap between the Rocker Lever and the valve stem, to prevent issues such as valvetrain noise or reduced engine efficiency.

Conclusion

In summary, part 5484231 Rocker Lever is a pivotal element in the engine’s valve train, ensuring the precise timing and operation of the engine’s valves. Its integration within the Rocker Lever Top Level Assembly and interaction with other components underscore its importance in maintaining engine performance and efficiency.

-

Goodnight, Nicholas, and Kirk VanGelder. Automotive Braking Systems CDX Master Automotive Technician Series. Jones Bartlett Learning, 2019.

↩ -

Brach, R. Matthew. SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety. SAE Books, 2023.

↩ -

Hilgers, Michael. Electrical Systems and Mechatronics, Second Edition. Springer Vieweg, 2023.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.