This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

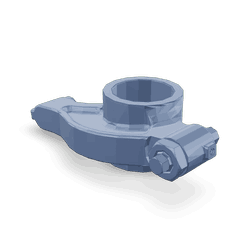

The Cummins 5539201 Rocker Arm is a component designed for use in heavy-duty truck engines. It facilitates the movement of the valves in response to the camshaft’s actions, playing a significant role in maintaining the engine’s performance and efficiency. This ensures that the truck operates smoothly under various conditions.

Basic Concepts of Rocker Arms

A rocker arm is a lever within an engine that acts on the valves. Its primary function is to transfer motion from the camshaft to the valves, allowing them to open and close at precise intervals. This interaction is fundamental to the engine’s operation, facilitating the intake and exhaust processes. The rocker arm amplifies the camshaft’s motion, ensuring that the valves open sufficiently to allow the necessary airflow for combustion 1.

Purpose of the 5539201 Rocker Arm

This part plays a role in the valve train mechanism of a truck engine. It converts the rotational motion of the camshaft into the linear motion required to operate the valves. This conversion ensures that the valves open and close in sync with the engine’s cycles, contributing to efficient combustion and overall engine performance 2.

Key Features

The 5539201 Rocker Arm is constructed from high-quality materials, ensuring durability and reliability under the demanding conditions of heavy-duty truck operation. Its design includes precision-machined surfaces for smooth operation and reduced friction. Additionally, the rocker arm may feature specific geometry and material treatments that enhance its performance and longevity.

Benefits

The use of the 5539201 Rocker Arm in a truck engine can lead to improved engine efficiency, as it ensures precise valve operation. Its durable construction contributes to the engine’s reliability, reducing the likelihood of unexpected failures. Furthermore, the enhanced performance of the valve train can lead to better fuel efficiency and overall engine health.

Installation Process

Installing the 5539201 Rocker Arm requires careful attention to detail to ensure proper function and longevity. The process involves removing the old rocker arm, cleaning the mounting area, and then positioning the new rocker arm in place. Specific tools may be required to adjust the rocker arm to the correct clearance, ensuring optimal valve operation. It is important to follow the manufacturer’s guidelines to avoid damage to the component or the engine.

Troubleshooting Common Issues

Common issues with rocker arms can include noise, leaks, or malfunctions. These problems may arise from improper installation, wear and tear, or manufacturing defects. Troubleshooting steps may involve inspecting the rocker arm and its associated components for signs of damage or wear, ensuring proper clearance and adjustment, and addressing any lubrication issues that may affect performance.

Maintenance Tips

Regular maintenance of the 5539201 Rocker Arm is key to ensuring its longevity and optimal performance. This includes periodic inspections for signs of wear or damage, ensuring proper lubrication, and adjusting the rocker arm as necessary to maintain the correct valve clearance. Adhering to the manufacturer’s recommended maintenance schedule can help prevent issues and extend the component’s lifespan.

Cummins Corporation

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and related technologies. With a history of innovation and quality, Cummins has established a strong reputation in the automotive and heavy-duty truck industries. The company’s commitment to excellence is reflected in its product range, which is designed to meet the demanding requirements of various applications.

Compatibility of Rocker Arm Part 5539201 with Cummins Engines

The Rocker Arm part 5539201, manufactured by Cummins, is designed to fit seamlessly into a variety of their engine models. This part is integral to the engine’s valve train system, ensuring proper valve operation and overall engine performance.

QSK38 Series

- QSK38 CM2150 MCRS

- QSK38 CM850 MCRS

The QSK38 series engines, specifically the CM2150 and CM850 models, are equipped with the Rocker Arm part 5539201. This part is crucial for maintaining the precise valve timing and operation necessary for these engines to function efficiently.

QSK50 Series

- QSK50 CM2150 K107

- QSK50 CM2150 MCRS

- QSK50 CM2350 K108

The QSK50 series engines, including the CM2150 K107, CM2150 MCRS, and CM2350 K108 models, also utilize the Rocker Arm part 5539201. This part ensures that the valve train operates smoothly, contributing to the engine’s reliability and performance.

The compatibility of the Rocker Arm part 5539201 across these various engine models underscores its versatility and importance in maintaining the integrity of the valve train system.

Role of Part 5539201 Rocker Arm in Engine Systems

The 5539201 Rocker Arm is an integral component in the operation of various engine systems, facilitating the transfer of motion from the camshaft to the valves. This transfer is essential for the precise timing of valve opening and closing, which directly influences engine performance, efficiency, and emissions.

In conjunction with the rocker lever, the 5539201 Rocker Arm amplifies the motion initiated by the camshaft. The rocker lever, often mounted on a pivot point, interacts with the rocker arm to convert the rotational motion of the camshaft into linear motion that operates the valves. This mechanical advantage ensures that the valves open and close with the necessary force and speed.

Additionally, the 5539201 Rocker Arm works in harmony with the valve springs. These springs are responsible for returning the valves to their closed position after being actuated. The rocker arm must be designed to withstand the forces exerted by these springs while maintaining smooth and reliable operation.

The interaction between the 5539201 Rocker Arm and the pushrods (in pushrod engine configurations) is another key aspect. Pushrods transmit the motion from the camshaft, located in the engine block, to the rocker arms situated in the cylinder head. The rocker arm then uses this motion to operate the valves.

Furthermore, the 5539201 Rocker Arm plays a role in the valve train system, which includes all components responsible for valve actuation. A well-designed valve train ensures minimal wear and maximum efficiency, contributing to the overall longevity and performance of the engine.

In overhead cam (OHC) engines, the 5539201 Rocker Arm may interact directly with the camshaft without the need for pushrods, reducing the number of moving parts and potentially improving engine responsiveness and efficiency.

Overall, the 5539201 Rocker Arm is a fundamental component that ensures the smooth and efficient operation of the valve train, contributing to the engine’s performance, durability, and reliability.

Conclusion

The Cummins 5539201 Rocker Arm is a critical component in the valve train system of heavy-duty truck engines. Its role in converting camshaft motion into valve operation ensures precise timing and efficient engine performance. The part’s durable construction, compatibility with various Cummins engine models, and the importance of regular maintenance highlight its significance in maintaining engine reliability and performance.

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.