3177713

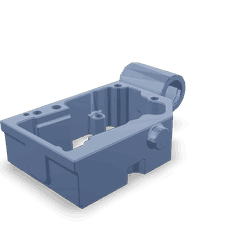

Rocker Lever Housing

Cummins®

AVAILABLE

3 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Rocker Lever Housing part number 3177713, manufactured by Cummins, is a significant component within the engine system of heavy-duty trucks. This part is integral to the operation of the engine’s valve train, ensuring precise and efficient valve actuation. Cummins, a renowned name in the engine manufacturing industry, is known for its commitment to quality and innovation, making the 3177713 a reliable choice for truck operators and fleet managers. This document provides an in-depth look at the Rocker Lever Housing 3177713, its function, features, and benefits, along with installation, troubleshooting, and maintenance tips.

Basic Concepts of Rocker Lever Housing

A rocker lever housing is a component that houses the rocker arms within an engine’s valve train. Its primary function is to provide a stable and secure environment for the rocker arms to operate, facilitating the transfer of motion from the camshaft to the valves 1. This transfer is crucial for the opening and closing of the engine’s valves at the correct times, which is essential for the engine’s combustion process. The rocker lever housing interacts with other components such as the camshaft, pushrods, and valves, playing a pivotal role in the mechanical operation of the engine.

Purpose of the 3177713 Rocker Lever Housing

The 3177713 Rocker Lever Housing is specifically designed to enhance the operation of truck engines. It contributes to the overall performance and efficiency of the engine by ensuring that the rocker arms are properly supported and aligned. This precise alignment and support are vital for maintaining the engine’s valve timing, which directly affects the engine’s power output, fuel efficiency, and emissions 2. By providing a robust and durable housing for the rocker arms, the 3177713 helps to maintain the integrity of the valve train under the demanding conditions of heavy-duty truck operation.

Key Features

The 3177713 Rocker Lever Housing boasts several key features that set it apart from other similar parts. It is constructed from high-quality materials that offer superior durability and resistance to wear and corrosion. The design of the housing includes precise machining and tolerances to ensure a perfect fit and optimal performance. Additionally, the 3177713 features unique characteristics such as enhanced cooling channels and improved sealing surfaces, which contribute to its overall effectiveness and longevity in the engine.

Benefits

Utilizing the 3177713 Rocker Lever Housing offers several benefits, including improved engine performance, increased durability, and enhanced reliability. These benefits translate to advantages for truck operators and fleet managers, such as reduced maintenance costs, extended engine life, and improved fuel efficiency 3. The robust construction and precise design of the 3177713 contribute to these benefits by ensuring that the valve train operates smoothly and efficiently, even under the most demanding conditions.

Installation Process

Installing the 3177713 Rocker Lever Housing requires careful attention to detail to ensure proper fitment and function. The process involves removing the old housing, cleaning the mounting surface, and carefully positioning the new housing in place. Special tools may be required to ensure that the housing is properly torqued and sealed. Following the manufacturer’s instructions and guidelines is crucial for a successful installation.

Troubleshooting Common Issues

Common problems associated with rocker lever housings can include leaks, wear, and misalignment. For the 3177713 specifically, troubleshooting may involve checking for proper sealing, inspecting for signs of wear or damage, and ensuring that the housing is correctly aligned with the rocker arms and other components. Addressing these issues promptly can help maintain the performance and reliability of the engine.

Maintenance Tips

Regular maintenance of the 3177713 Rocker Lever Housing is key to ensuring its longevity and optimal performance. This includes periodic inspections for signs of wear, damage, or leaks, as well as ensuring that all seals and gaskets are in good condition. Following the manufacturer’s recommended maintenance schedule and guidelines will help keep the housing in top condition, contributing to the overall health and efficiency of the engine.

Cummins: A Brief Overview

Cummins is a leading manufacturer in the engine industry, known for its history of innovation, quality, and reliability. With a strong reputation for producing high-performance engine components, Cummins continues to be a trusted name among truck operators and fleet managers. Their commitment to excellence is evident in the design and manufacturing of the 3177713 Rocker Lever Housing, showcasing their dedication to providing durable, efficient, and reliable engine parts.

Role of Part 3177713 Rocker Lever Housing in Engine Systems

The part 3177713 Rocker Lever Housing is an integral component within the engine system, facilitating the efficient operation of several key elements. It is designed to house and support the rocker levers, which are pivotal in transferring motion from the camshaft to the valves. This transfer is essential for the precise timing of valve openings and closings, directly influencing engine performance and efficiency.

Interaction with Camshaft and Gear

The Rocker Lever Housing interfaces directly with the camshaft and gear assembly. As the camshaft rotates, driven by the engine’s crankshaft, it actuates the rocker levers housed within the 3177713 assembly. These levers then transmit motion to the valve train, ensuring that the intake and exhaust valves open and close in sync with the engine’s combustion cycle.

Support for Injectors and Oil Control Valve

In modern engine systems, the Rocker Lever Housing also provides a stable platform for injectors and the oil control valve. The injectors, responsible for fuel delivery into the combustion chamber, must be securely mounted to ensure accurate fuel metering. Similarly, the oil control valve, which regulates oil flow to various engine components, benefits from the stable environment offered by the housing, ensuring consistent lubrication and performance.

Integration with Aftercooler Core and Plumbing

In turbocharged engine setups, the Rocker Lever Housing may also interact with the aftercooler core and its associated plumbing. The aftercooler, which cools the compressed air from the turbocharger, often requires precise placement to maximize efficiency. The housing can serve as a reference point for mounting brackets and protective covers, ensuring that the aftercooler components are correctly aligned and protected.

Structural and Protective Functions

Beyond its dynamic roles, the 3177713 Rocker Lever Housing also offers structural integrity and protection. It shields the delicate rocker levers and associated components from debris and excessive heat, prolonging their operational life. Additionally, it may incorporate lifting brackets for easier installation and removal during maintenance procedures, enhancing the overall serviceability of the engine.

Enhancement of Performance Parts

For engines equipped with performance parts, the Rocker Lever Housing plays a significant role in maintaining the integrity and efficiency of these upgrades. High-performance camshafts, for instance, demand precise and robust support to handle increased stress and higher RPMs. The housing ensures that these components operate within their designed parameters, contributing to the engine’s overall performance gains.

Conclusion

The 3177713 Rocker Lever Housing is a critical component in Cummins engines, playing a vital role in the efficient operation of the valve train. Its robust construction, precise design, and integration with other engine components contribute to improved engine performance, durability, and reliability. Regular maintenance and proper installation are essential to ensure the longevity and optimal performance of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.