This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

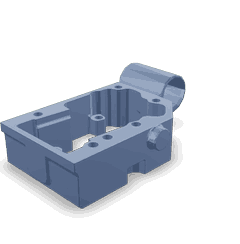

The 3202194 Rocker Lever Housing, manufactured by Cummins, is a critical component in the operation of commercial trucks. Cummins, a renowned name in the commercial truck industry, produces a range of parts designed to enhance engine performance and reliability. This part plays a significant role in the engine’s valve train system.

Basic Concepts of Rocker Lever Housing

A Rocker Lever Housing is a component within an engine’s valve train system. Its primary function is to house and support the rocker arms, which are essential for the operation of the engine’s valves. The rocker arms are actuated by the camshaft and are responsible for opening and closing the engine’s valves at precise intervals. The housing ensures that the rocker arms are correctly positioned and supported, allowing for efficient and reliable valve operation 1.

Purpose of the 3202194 Rocker Lever Housing

This Cummins part is designed to support the valve train system of a truck engine. It provides a stable and secure environment for the rocker arms, which are crucial for the operation of the engine’s valves. By housing the rocker arms, the 3202194 ensures that they are correctly aligned and supported, contributing to the overall efficiency and reliability of the engine.

Key Features

The 3202194 Rocker Lever Housing features several attributes that enhance its performance. It is constructed from high-quality materials, ensuring durability and resistance to wear. The design of the housing allows for easy installation and removal, facilitating maintenance procedures. Additionally, the housing is engineered to provide optimal support for the rocker arms, ensuring precise and reliable valve operation.

Benefits

The 3202194 Rocker Lever Housing offers several benefits to the operation of a truck engine. Its robust construction and precise design contribute to improved engine efficiency, as the rocker arms are able to operate with minimal friction and maximum reliability. The durability of the housing ensures long-term performance, reducing the need for frequent replacements. Furthermore, the reliable operation of the rocker arms, supported by the housing, contributes to the overall reliability of the engine.

Installation Process

Installing the 3202194 Rocker Lever Housing requires careful attention to detail. Begin by ensuring that the engine is clean and free from debris. Using the appropriate tools, remove the old housing and inspect the area for any damage. Place the new housing into position, ensuring that it is correctly aligned with the rocker arms and other components. Secure the housing in place using the recommended fasteners, and perform a final check to ensure that all components are correctly installed and aligned.

Common Issues and Troubleshooting

Common issues with the 3202194 Rocker Lever Housing may include wear or damage to the housing, misalignment of the rocker arms, or issues with the fasteners. To troubleshoot these issues, begin by inspecting the housing for any signs of wear or damage. Ensure that the rocker arms are correctly aligned and supported by the housing. Check the fasteners for proper installation and tightness. If issues persist, consult the manufacturer’s guidelines or seek professional assistance.

Maintenance Tips

Regular maintenance of the 3202194 Rocker Lever Housing is essential for ensuring its longevity and optimal performance. Inspect the housing during routine engine maintenance checks, looking for any signs of wear or damage. Ensure that the rocker arms are correctly aligned and supported by the housing. Keep the area clean and free from debris, and address any issues promptly to prevent further damage.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for producing high-quality, reliable components for the commercial truck industry. The company’s product range includes engines, powertrains, and aftermarket parts, all designed to enhance the performance and reliability of commercial vehicles.

Cummins Rocker Lever Housing Part 3202194 Compatibility

The Cummins Rocker Lever Housing part number 3202194 is designed to fit seamlessly with several engine models, ensuring optimal performance and reliability. This part is integral to the engine’s valve train system, providing a stable housing for the rocker levers that operate the engine’s valves.

K19 and K38 Engines

The 3202194 is compatible with both the K19 and K38 engines. These engines share similar design characteristics and operational parameters, making this part a suitable fit for both models. The housing ensures that the rocker levers are properly aligned and supported, facilitating smooth and efficient valve operation.

K50 Engine

Similarly, the K50 engine also benefits from the use of the 3202194. This part is engineered to meet the specific requirements of the K50 engine, ensuring that the rocker levers function correctly under the engine’s operating conditions. The compatibility of this housing with the K50 engine underscores its versatility and robustness.

Grouping of Engines

When considering the compatibility of the 3202194, it is useful to group the K19 and K38 engines together due to their shared design and operational features. The K50 engine, while distinct, also integrates this housing effectively, highlighting the part’s broad applicability across different engine models. This grouping helps in understanding the part’s role and its importance in maintaining the integrity of the engine’s valve train system.

Role of Part 3202194 Rocker Lever Housing in Engine Systems

The 3202194 Rocker Lever Housing is an integral component in the orchestration of various engine systems, ensuring optimal performance and efficiency. It interfaces directly with the camshaft and gear assembly, translating the rotational motion of the camshaft into linear motion for the rocker lever. This motion is essential for the opening and closing of the engine’s valves, a process that is fundamental to the intake and exhaust cycles.

In high-performance engines, the Rocker Lever Housing is often part of an upgraded system that includes performance parts designed to enhance engine responsiveness and power output. The housing must be precisely machined to accommodate these components, ensuring that there is minimal play and maximum efficiency in the valve operation.

The housing also plays a role in the management of engine lubrication. It is strategically positioned to facilitate the flow of oil to the rocker lever and camshaft, reducing friction and wear. In some engine designs, the Rocker Lever Housing may incorporate passages for the oil control valve, allowing for dynamic adjustment of oil flow to meet varying engine loads and speeds.

In turbocharged engine systems, the Rocker Lever Housing’s location near the cylinder head means it is in close proximity to the aftercooler core and aftercooler plumbing. This setup ensures that the housing and associated components benefit from the reduced temperatures of the charge air, which can lead to increased reliability and performance.

Moreover, the Rocker Lever Housing is often secured to the engine block using a lifting bracket. This bracket not only aids in the installation and removal of the housing but also provides structural rigidity, which is important for maintaining the precise alignment of the rocker levers during engine operation.

Conclusion

In summary, the 3202194 Rocker Lever Housing is a multifaceted component that interacts with various engine systems to ensure efficient valve operation, effective lubrication, and structural integrity within the engine assembly. Regular maintenance and proper installation are crucial for maximizing the performance and longevity of this part.

-

Ribbens, W. B. (2003). Understanding Automotive Electronics. Elsevier Science.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.