This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 205138 Rocker Lever is a critical component in commercial truck engines, designed to enhance the operation and efficiency of the engine’s valve train. Understanding its function and significance provides valuable insight into engine mechanics and the role of each component in ensuring optimal performance.

Basic Concepts of Rocker Levers

A rocker lever, or rocker arm, is a pivotal component in an engine’s valve train. It operates on the principle of leverage, amplifying the motion of the camshaft to open and close the engine’s valves. This mechanism allows for precise control over the timing and duration of valve events, which are essential for engine performance. The rocker lever interacts with the camshaft, pushrods (in pushrod engines), and valves, facilitating the transfer of motion and force within the engine system 1.

Purpose of the 205138 Rocker Lever

This Cummins part plays a role in the operation of a truck engine by transferring motion from the camshaft to the valves. It ensures that the valves open and close at the correct times, allowing for the intake of air and fuel and the exhaust of combustion gases. This component works in conjunction with other parts of the valve train, including the camshaft, pushrods, and valve springs, to maintain the engine’s operational cycle 2.

Key Features

The 205138 Rocker Lever is characterized by several key features that enhance its functionality and durability. It is typically made from high-strength materials to withstand the rigors of engine operation. The design may include features such as a hardened roller tip for reduced friction and wear, and precise machining for accurate valve actuation. Additionally, the lever may have adjustments for valve lash, allowing for fine-tuning of the valve train’s operation.

Benefits of Using the 205138 Rocker Lever

Incorporating this part into a truck engine can lead to several advantages. Its design and material composition contribute to improved engine performance by ensuring efficient valve operation. The component’s durability and reliability reduce the likelihood of premature failure, leading to lower maintenance costs and increased engine lifespan. Furthermore, the precise control over valve timing and lift can enhance fuel efficiency and power output.

Installation Process

Installing the 205138 Rocker Lever requires careful attention to detail to ensure proper function and longevity. The process involves removing the old rocker lever, inspecting the camshaft and valve seats for wear, and then installing the new lever. Tools such as a torque wrench may be necessary to secure the lever in place. It is important to follow the manufacturer’s guidelines for installation to avoid damage to the component or engine.

Troubleshooting Common Issues

Common problems associated with the 205138 Rocker Lever may include noise from the valve train, decreased engine performance, or valve train component failure. Troubleshooting steps may involve inspecting the lever for signs of wear or damage, checking the valve clearance, and ensuring that all components of the valve train are properly lubricated. Addressing these issues promptly can prevent further damage and maintain engine efficiency.

Maintenance Tips

Regular maintenance of the 205138 Rocker Lever is key to ensuring its longevity and optimal performance. This includes periodic inspection for wear or damage, ensuring proper lubrication, and adjusting valve clearance as necessary. Following the manufacturer’s recommended maintenance schedule can help prevent issues and extend the life of the component.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the commercial truck industry. The company’s product range includes a variety of engines and components designed to meet the demanding requirements of commercial applications, demonstrating a commitment to excellence and customer satisfaction.

Compatibility of 205138 Rocker Lever

The 205138 Rocker Lever is designed to fit seamlessly with a range of Cummins engines, ensuring optimal performance and reliability. This component is integral to the engine’s valve train system, facilitating the smooth operation of the engine’s valves.

K19 Engine

The K19 engine is one of the models that can utilize the 205138 Rocker Lever. This engine is known for its robust design and efficient performance, making it suitable for various applications.

K38 Engine

Similarly, the K38 engine is compatible with the 205138 Rocker Lever. This engine is designed to deliver high power output and durability, making it a popular choice in demanding environments.

K50 Engine

The K50 engine also integrates the 205138 Rocker Lever into its valve train system. This engine is engineered to provide excellent fuel efficiency and performance, making it ideal for both commercial and industrial use.

Grouping of Engines

The K19, K38, and K50 engines share common design principles and components, including the 205138 Rocker Lever. This commonality allows for easier maintenance and part compatibility across these engine models, simplifying the repair and replacement process for technicians and operators.

Role of Part 205138 Rocker Lever in Engine Systems

The 205138 Rocker Lever is an integral component within the engine system, facilitating the transfer of motion from the camshaft to the valves. This transfer is essential for the proper functioning of the engine’s intake and exhaust processes.

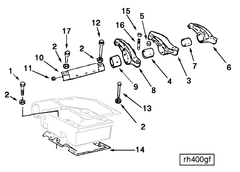

Interaction with Base Components

The Rocker Lever, identified as part 205138, operates in conjunction with the base part of the engine. The base part serves as the foundational structure upon which the Rocker Lever is mounted. This mounting allows the Rocker Lever to pivot and transmit the camshaft’s rotational motion into a linear motion that actuates the valves.

Functionality within the System

As the camshaft rotates, it pushes against one end of the Rocker Lever. This action causes the lever to pivot on its fulcrum, which is typically located on the base part. The opposite end of the Rocker Lever then exerts force on the valve stem, opening the valve. Once the camshaft lobe moves past the point of contact, the valve spring pulls the valve closed, and the cycle repeats.

Coordination with Other Parts

The efficiency of the Rocker Lever is also dependent on its interaction with other parts within the engine system. For instance, the pushrods (in pushrod engines) transmit motion from the camshaft to the Rocker Lever. In overhead camshaft (OHC) engines, the Rocker Lever may be directly actuated by the camshaft. Additionally, the valve springs play a role in ensuring that the valves close properly after being opened by the Rocker Lever.

Importance of Precision

The precise operation of the Rocker Lever is vital for maintaining the engine’s performance. Any deviation in the lever’s movement can lead to improper valve timing, which in turn affects the engine’s efficiency, power output, and emissions. Therefore, the Rocker Lever must be designed and manufactured to exacting standards to ensure consistent and reliable performance within the engine system 3.

Conclusion

The Cummins 205138 Rocker Lever is a vital component in the valve train system of commercial truck engines. Its precise operation ensures efficient valve actuation, contributing to the overall performance and reliability of the engine. Regular maintenance and proper installation are essential to maximize the benefits of this component and ensure the longevity of the engine system.

-

Fischer, R., Kucukay, F., Jurgens, G., Najork, R., & Pollak, B. (2015). The Automotive Transmission Book Powertrain. Springer.

↩ -

Eret, A. (2024). Dynamic and Fatigue Assessment of Heavy-Duty Engine Valves. Springer Nature.

↩ -

Fischer, R., Kucukay, F., Jurgens, G., Najork, R., & Pollak, B. (2015). The Automotive Transmission Book Powertrain. Springer.

↩

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.