This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 4003913 Rocker Lever is a component designed for use in commercial trucks. It serves a specific function within the engine’s valve train, contributing to the overall efficiency and performance of the vehicle. Understanding its purpose and significance is key to maintaining and optimizing truck operations.

Basic Concepts of Rocker Levers

A rocker lever, also known as a rocker arm, is a pivotal component in an engine’s valve train. It operates on the principle of leverage, amplifying the motion of the camshaft to open and close the engine’s valves. This mechanism ensures that the valves open and close at the precise moments required for optimal engine performance 1.

Role of the 4003913 Rocker Lever in Truck Operation

The 4003913 Rocker Lever plays a role in the operation of a truck by transferring motion from the camshaft to the valves. It interacts with the camshaft, pushrods, and valves, ensuring that the valves open and close in sync with the engine’s cycles. This interaction is vital for the engine’s combustion process, affecting both performance and fuel efficiency 2.

Key Features of the 4003913 Rocker Lever

The 4003913 Rocker Lever is characterized by its robust material composition, typically involving high-strength alloys to withstand the rigors of commercial truck operation. Its design includes precise machining for smooth operation and durability. Unique characteristics may include specific geometries or coatings that enhance performance and longevity 3.

Benefits of Using the 4003913 Rocker Lever

Incorporating the 4003913 Rocker Lever into a truck’s engine system can lead to improved performance, increased durability, and enhanced efficiency. Its design and material composition contribute to these benefits, making it a valuable component for commercial truck applications.

Installation Process

Installing the 4003913 Rocker Lever requires careful attention to detail. The process involves removing the old rocker lever, inspecting the camshaft and valve components for wear, and then positioning the new rocker lever. Proper torque specifications must be followed to ensure secure fastening without over-tightening, which could lead to damage.

Common Issues and Troubleshooting

Common issues with the 4003913 Rocker Lever may include wear, noise, or failure to operate correctly. Troubleshooting these problems often involves inspecting the lever for signs of wear, checking the clearances between components, and ensuring that all fasteners are properly torqued. Addressing these issues promptly can prevent more significant engine problems.

Maintenance Tips

Regular maintenance of the 4003913 Rocker Lever involves periodic inspection for wear and proper operation. Lubrication, according to the manufacturer’s recommendations, is also crucial to ensure smooth operation and longevity. Keeping the engine clean and free of contaminants can further protect the rocker lever and associated components.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a strong reputation in the commercial truck industry, Cummins is known for its high-quality, reliable, and efficient engine components, including the 4003913 Rocker Lever. The company’s commitment to innovation and customer satisfaction has established it as a trusted name in the industry.

Compatibility of 4003913 with Cummins Engines

The Rocker Lever part number 4003913 is compatible with several Cummins engine models. This part is designed to fit seamlessly within the engine architecture, ensuring smooth operation and longevity of the engine.

ISM Series Engines

- ISM CM570

- ISM CM570/870

- ISM CM876

- ISM11 CM876 SN

L10 Series Engines

- L10 CELECT

M11 Series Engines

- M11 CELECT

- M11 CELECT PLUS

- M11 MECHANICAL

QSM11 Series Engines

- QSM11 CM570

- QSM11 CM876

Understanding the Integration of Part 4003913 Rocker Lever in Engine Systems

The part 4003913 Rocker Lever is a component in the operation of various engine systems, particularly in the valve train mechanism. Its primary function is to transfer motion from the camshaft to the valves, ensuring precise and efficient engine performance.

Interaction with the Rocker

The Rocker Lever, identified as part 4003913, is mounted on a pivot point and is directly actuated by the cam lobe. As the camshaft rotates, the cam lobe pushes against the Rocker, causing it to pivot. This pivoting motion is then transferred to the valve through the connection with the valve stem.

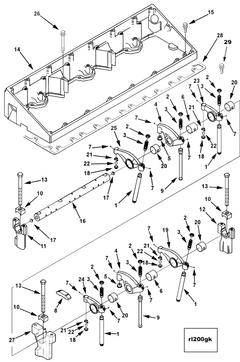

Role in the Rocker Top Level Assembly

Within the Rocker Top Level Assembly, the Rocker Lever plays a significant role. This assembly typically includes the Rocker Lever, pushrods, and other supporting components. The Rocker Lever’s motion, induced by the camshaft, is transmitted through the pushrod to the valve below. This ensures that the valve opens and closes at the correct times, maintaining the engine’s timing and efficiency.

Coordination with the Lever

The Lever component, often part of a more complex assembly, works in tandem with the Rocker Lever. In some engine designs, the Lever may be used to adjust the valve clearance or to provide additional mechanical advantage. The interaction between the Rocker Lever and the Lever ensures that the valve operation is smooth and consistent, contributing to the overall reliability of the engine.

Comprehensive Valve Train Operation

In summary, the part 4003913 Rocker Lever is integral to the valve train’s operation. It ensures that the valves open and close in sync with the engine’s requirements, facilitating optimal air and fuel intake and exhaust processes. The precise motion transfer from the camshaft to the valves, mediated by the Rocker Lever, is fundamental to the engine’s performance and durability.

Conclusion

The 4003913 Rocker Lever is a critical component in the valve train of Cummins engines, ensuring efficient and reliable operation of commercial trucks. Its robust design, precise machining, and compatibility with various Cummins engine models make it a valuable asset for maintaining and optimizing truck performance. Regular maintenance and prompt troubleshooting of common issues are essential for the longevity and efficiency of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.