This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The BM95161 Rocker Lever is a component manufactured by Cummins, a well-established name in the commercial truck industry. This rocker lever is designed for use in commercial trucks, where it contributes to the efficient operation of the engine system. Cummins is renowned for its high-quality engine components, and the BM95161 is no exception, offering reliability and performance in demanding truck applications 1.

Basic Concepts of Rocker Levers

A rocker lever is a mechanical component that operates on the principle of leverage to amplify force. In mechanical systems, rocker levers are used to transfer motion from one part of a system to another, often increasing the force applied in the process. This is achieved through the lever’s fulcrum, which allows it to pivot and exert greater force on one side than is applied on the other 2.

Role of the BM95161 Rocker Lever in Truck Operation

The BM95161 Rocker Lever plays a specific role in the operation of a truck by interacting with the engine’s valve train. It is responsible for transferring motion from the camshaft to the valves, ensuring that they open and close at the precise moments required for optimal engine performance. This component’s accurate operation is vital for maintaining the engine’s efficiency and power output 3.

Key Features

The BM95161 Rocker Lever is characterized by several key features that enhance its functionality and durability. It is constructed from high-quality materials that can withstand the rigors of commercial truck operation. The design of the rocker lever includes precise engineering to ensure smooth operation and minimal wear. Additionally, it may feature unique attributes such as a specific geometry or surface treatments that improve its performance and longevity.

Benefits

The incorporation of the BM95161 Rocker Lever into a truck’s engine system offers several benefits. It contributes to improved engine efficiency by ensuring that the valves operate with precision. This can lead to better fuel economy and reduced emissions. The rocker lever’s reliable operation also enhances the overall reliability of the engine, reducing the likelihood of unexpected failures. Furthermore, its design may provide performance enhancements, such as increased power output or improved engine responsiveness.

Troubleshooting and Maintenance

Common issues with the BM95161 Rocker Lever may include wear, noise, or failure to operate correctly. Troubleshooting steps may involve inspecting the lever for signs of damage, checking the clearances within the valve train, and ensuring that all related components are in good condition. Regular maintenance practices, such as lubrication and inspection during routine service intervals, can help to ensure the longevity and optimal performance of the rocker lever.

Compatibility with Cummins Engines

The BM95161 Rocker Lever is designed to be compatible with several Cummins engine models. This part is integral to the engine’s valve train system, ensuring proper valve operation and timing. Here are the engines with which this rocker lever is compatible:

-

G855 and G855 CM558: These engines utilize the rocker lever for managing the valve actuation mechanism. The BM95161 fits seamlessly into the design, providing reliable performance and durability.

-

GTA855 CM558 (CM2358) G101: This engine series also incorporates the BM95161 rocker lever. The compatibility ensures that the valve train operates smoothly, contributing to the engine’s overall efficiency and longevity.

-

N14 G and N14 MECHANICAL: The rocker lever BM95161 is essential for these engines, facilitating precise valve timing and operation. Its design aligns with the mechanical requirements of the N14 series.

-

NH/NT 855: This engine model is another beneficiary of the BM95161 rocker lever. The part’s design ensures that the valve train functions correctly, supporting the engine’s performance and reliability.

-

V28: The BM95161 rocker lever is also compatible with the V28 engine. It plays a role in the valve actuation process, ensuring that the engine operates efficiently and reliably.

The compatibility of the BM95161 rocker lever across these engines highlights its versatility and importance in maintaining the functionality of the valve train system.

Role of BM95161 in Engine Systems

The BM95161 Rocker Lever is an integral component within various engine systems, facilitating efficient operation and performance. Its role is multifaceted, interacting with several key components to ensure optimal functionality.

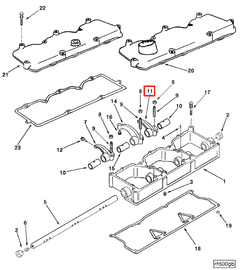

Interaction with Base Parts and Housing Assemblies

The BM95161 Rocker Lever is designed to fit precisely within the rocker arm housing and rocker housing assembly. These housings provide the structural framework necessary for the lever to operate effectively. The lever is secured within the rocker housing, which is often part of a larger housing assembly. This assembly ensures that the lever is correctly positioned to engage with other engine components.

Coordination with Engine Brake and Exhaust Brake Systems

In engine brake and exhaust brake systems, the BM95161 Rocker Lever plays a role in modulating the braking force. It works in conjunction with the engine brake housing and the exhaust brake housing to control the release and application of braking pressure. The lever’s movement is critical in these systems, as it translates the mechanical action into the desired braking effect.

Integration with Rocker Arm and Rocker Housing

The rocker lever is an essential part of the rocker arm mechanism. It is housed within the rocker arm housing, which is a critical component in the valve train of an engine. The lever’s interaction with the rocker arm allows for the precise control of valve timing and lift, which are vital for engine performance. The rocker housing, often referred to as the rocker hsg, provides the necessary support and alignment for the lever to function correctly.

Role in On-Board Spares and Engine Spares Kit

The BM95161 Rocker Lever is frequently included in on-board spares and engine spares kits. This inclusion ensures that maintenance crews have immediate access to replacement parts, minimizing downtime. The lever’s design allows for easy installation into the rocker lever housing or rocker housing assembly, facilitating quick repairs and maintenance.

Functionality in Set of Spares and Control Systems

When part of a set of spares, the BM95161 Rocker Lever ensures that engines can be rapidly returned to service following component failure. In control systems, the lever’s accurate movement is essential for maintaining the desired engine parameters. Its integration with control mechanisms allows for fine-tuning of engine performance, ensuring that the engine operates within specified limits.

Support from Engine Brace and Housing Engine Brace

The hsg engine brace and other supporting structures play a role in maintaining the alignment and stability of the BM95161 Rocker Lever. These braces ensure that the lever can operate under varying engine conditions without deviation, contributing to the overall reliability and performance of the engine system.

Conclusion

The BM95161 Rocker Lever by Cummins is a critical component in the operation of commercial truck engines. Its precise design and high-quality materials ensure reliable performance and durability. The rocker lever’s role in the valve train system is essential for maintaining engine efficiency and power output. Regular maintenance and troubleshooting are key to ensuring the longevity of this Cummins part. Its compatibility with various Cummins engine models underscores its versatility and importance in the commercial truck industry.

-

Ribbens, W. B. (2003). Understanding Automotive Electronics. Elsevier Science.

↩ -

Dixon, J. (2014). Modern Diesel Technology: Heating, Ventilation, Air Conditioning, Refrigeration, 2nd Edition. Cengage Learning.

↩ -

Huzij, R., Spano, A., & Bennett, S. (2019). Modern Diesel Technology: Heavy Equipment Systems. Cengage Learning.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.