This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The BM95162 Rocker Lever, a component manufactured by Cummins, is integral to the operation of commercial truck engines. This part facilitates the efficient transfer of motion within the engine’s valve train, ensuring precise valve operation.

Basic Concepts of Rocker Levers

A rocker lever, or rocker arm, is a lever used in mechanical systems, particularly in internal combustion engines, to transfer and amplify motion from one component to another. In an engine, it connects the camshaft to the valves, enabling the camshaft’s rotational motion to open and close the valves at precise intervals 1.

Purpose of the BM95162 Rocker Lever

This Cummins part plays a specific role in the operation of a truck engine. It interacts with the camshaft and the engine’s valves, transferring and amplifying the camshaft’s motion to open and close the valves. This ensures that the air-fuel mixture enters the combustion chamber at the correct time and that exhaust gases are expelled efficiently 2.

Key Features

The BM95162 is characterized by several distinctive features. It is constructed from high-quality materials that provide durability and resistance to wear. The design includes precise machining to ensure smooth operation and accurate valve actuation. Additionally, the rocker lever may feature unique attributes such as a specific geometry or surface treatments that enhance its performance and longevity 3.

Benefits

This part offers several advantages. Its high-quality construction and precise design contribute to improved engine efficiency by ensuring accurate and reliable valve operation. The durability of the rocker lever reduces the need for frequent replacements, contributing to lower maintenance costs. Furthermore, the enhanced performance of the rocker lever can lead to better overall engine performance 4.

Installation and Integration

Installing the BM95162 in a truck engine requires careful attention to detail. The process involves removing the old rocker lever, inspecting the camshaft and valve components for wear, and then installing the new rocker lever. Special tools may be required to ensure proper installation and to avoid damage to the engine components. It is important to follow the manufacturer’s guidelines to ensure the rocker lever is correctly integrated into the engine system.

Troubleshooting Common Issues

Rocker levers can encounter issues such as wear, improper adjustment, or damage. Common problems include noisy operation, valve train clatter, or engine misfires. Diagnosing these issues involves inspecting the rocker lever for signs of wear or damage, checking the valve clearances, and ensuring the camshaft and valve components are in good condition. Potential solutions may include adjusting the valve clearances, replacing worn components, or performing a more comprehensive engine service if necessary.

Maintenance Tips

To ensure the longevity and optimal performance of the BM95162, regular maintenance is recommended. This includes periodic inspections for signs of wear or damage, checking and adjusting the valve clearances as necessary, and ensuring the rocker lever and associated components are clean and free from contaminants. Following the manufacturer’s maintenance schedule and guidelines will help maintain the efficiency and reliability of the engine’s valve train.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation in the commercial truck industry for producing reliable and high-performance engines and components. The company’s product range includes a variety of engines, powertrains, and aftermarket parts designed to meet the demanding requirements of commercial trucking applications.

Compatibility with Cummins Engines

The BM95162 is designed to fit seamlessly into several Cummins engine models. This part is integral to the engine’s valve train system, ensuring proper valve operation and overall engine performance.

G855 Series Engines

The BM95162 is compatible with the G855 engine. This engine is known for its robust design and reliability, making it a popular choice for various applications.

G855 CM558 Series Engines

The G855 CM558 engine also utilizes the BM95162. This variant of the G855 engine incorporates advanced features that enhance performance and efficiency.

GTA855 CM558 (CM2358) G101 Series Engines

The GTA855 CM558 (CM2358) G101 engine is another model that integrates the BM95162. This engine is designed for heavy-duty applications, providing the strength and durability needed for demanding tasks.

N14 Series Engines

The BM95162 is also compatible with the N14 engine, including both the standard N14 G and the N14 MECHANICAL variants. These engines are renowned for their power and reliability, making them suitable for a wide range of uses.

NH/NT 855 Series Engines

The NH/NT 855 engine is another model that fits the BM95162. This engine is designed for agricultural and industrial applications, offering the performance and efficiency required for these sectors.

V28 Series Engines

Lastly, the V28 engine is compatible with the BM95162. This engine is known for its versatility and is used in various applications where reliability and performance are critical.

Role of BM95162 in Engine Systems

The BM95162 is an integral component within various engine systems, facilitating the conversion of linear piston motion into rotational motion for the camshaft. This conversion is essential for the operation of the engine’s valve train, ensuring precise timing for the opening and closing of intake and exhaust valves.

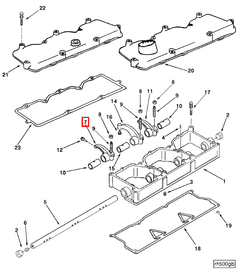

Interaction with Base Parts and Housing Components

The BM95162 interfaces directly with the rocker arm housing and rocker housing assembly. These housings provide the structural support necessary for the rocker lever to function effectively. The lever is mounted on a pivot point within the housing, allowing it to oscillate as the camshaft lobe pushes against it. This oscillation is then transferred to the valves via the rocker lever, ensuring they open and close in sync with the engine’s operation.

Integration with Engine Brake Systems

In engine brake systems, the BM95162 plays a significant role in modulating the braking force. It works in conjunction with the engine brake control to adjust the valve timing, which in turn affects the compression and decompression cycles of the engine. This adjustment is vital for the effective deployment of the exhaust brake, which uses the engine’s compression to slow down the vehicle without relying solely on the friction brakes.

Contribution to On-Board Spares and Engine Spares Kit

The inclusion of the BM95162 in on-board spares and engine spares kits underscores its importance in maintaining engine functionality. Should a rocker lever fail, having a spare on hand allows for quick replacement, minimizing downtime. This is particularly important in scenarios where immediate repairs are necessary to keep the engine running efficiently.

Role in Rocker Lever Housing and Housing Assembly Rocker

The rocker lever housing and housing assembly rocker are designed to encase and protect the BM95162. These components ensure that the lever operates within a controlled environment, shielded from contaminants and excessive wear. The housing also facilitates the lubrication of the rocker lever, which is essential for reducing friction and prolonging the component’s lifespan.

Functionality in Rocker Housing and Rocker HSG

The rocker housing and rocker HSG (housing) are critical in providing a stable platform for the BM95162. These components are engineered to withstand the high temperatures and pressures present within the engine compartment, ensuring that the rocker lever can perform reliably under demanding conditions.

Interaction with RUR and HSG Engine Brace

The RUR (rocker lever housing) and HSG engine brace work in tandem with the BM95162 to maintain the structural integrity of the valve train. The engine brace provides additional support to the housing, ensuring that the rocker lever’s movements are precise and consistent. This precision is essential for the overall performance and longevity of the engine.

Importance in Set of Spares

Including the BM95162 in a set of spares is a strategic decision for maintenance and repair operations. Having a readily available spare allows mechanics to address issues promptly, reducing the risk of more severe engine damage and extending the engine’s operational life.

Conclusion

The BM95162 is a key component in the intricate dance of parts that make up an engine’s valve train. Its interactions with various housing components, brake systems, and spare parts kits are designed to ensure the engine operates smoothly, efficiently, and reliably.

-

Schneider, Wolf-Henning. Pistons and Engine Testing. Springer Nature, 2016.

↩ -

Boyce, Meherwan P. Gas Turbine Engineering Handbook, Second Edition. Gulf Professional Publishing, 2002.

↩ -

Reif, Konrad. Automotive Mechatronics. Springer Vieweg, 2015.

↩ -

Rendle, Steve, and Martynn Randall. Haynes Diesel Engine Systems and Data Book. Haynes Publishing, 2000.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.