This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Hexagon Head Cap Screw is a common fastening component utilized extensively in the assembly and maintenance of commercial trucks. This screw is characterized by its hexagonal head, which allows for efficient tightening and loosening using standard tools. Cummins Inc., a well-regarded manufacturer in the commercial truck industry, produces a variety of automotive components, including the 181210 Hexagon Head Cap Screw. This part is designed to meet the rigorous demands of truck operations, ensuring reliable performance and durability 2.

Basic Concepts of Hexagon Head Cap Screws

A Hexagon Head Cap Screw is a type of fastener that features a hexagonal head and a threaded shaft. The hexagonal shape of the head is significant because it provides a larger surface area for tool engagement, allowing for more torque to be applied without rounding off the corners. The cap feature at the end of the screw serves to cover and protect the fastened area, preventing debris and contaminants from entering. This design enhances the screw’s functionality in various fastening applications, making it a preferred choice in the automotive industry 1.

Purpose of the 181210 Hexagon Head Cap Screw in Truck Operation

The 181210 Hexagon Head Cap Screw plays a specific role in the assembly and maintenance of commercial trucks. It is commonly used in applications where secure and durable fastening is required. Examples of its use within truck components include attaching engine covers, securing chassis parts, and fastening various brackets and supports. Its design ensures that it can withstand the vibrations and stresses encountered during truck operation, maintaining a tight and reliable connection 2.

Key Features of the 181210 Hexagon Head Cap Screw

The 181210 Hexagon Head Cap Screw is defined by several primary characteristics. It is typically made from high-strength materials such as alloy steel, which provides excellent durability and resistance to wear. The screw features a coarse thread type, which allows for quick and secure fastening. Additionally, it may include unique design elements such as a corrosion-resistant coating to enhance its performance in harsh environments 1.

Benefits of Using the 181210 Hexagon Head Cap Screw

The 181210 Hexagon Head Cap Screw offers several advantages. Its durable material composition ensures long-lasting performance, even under demanding conditions. The screw’s resistance to vibration helps maintain a secure connection over time, reducing the need for frequent re-tightening. Additionally, the hexagonal head allows for easy use with standard tools, simplifying the installation and removal process 2.

Installation Guidelines

Proper installation of the 181210 Hexagon Head Cap Screw is crucial for ensuring secure and effective fastening. Begin by cleaning the mating surfaces to remove any debris or contaminants. Use a torque wrench to tighten the screw to the manufacturer’s specified torque settings, ensuring that it is neither over-tightened nor under-tightened. It is also important to periodically check the screw’s tightness during the initial operation phase to prevent any loosening 1.

Maintenance and Troubleshooting

Regular maintenance of the 181210 Hexagon Head Cap Screw involves inspecting it for signs of wear, corrosion, or loosening. If corrosion is detected, clean the screw and mating surfaces, and apply a corrosion-resistant coating if necessary. Should the screw become loose, re-tighten it to the specified torque settings. In cases where the screw is damaged or worn, replace it with a new one to ensure continued reliable performance 2.

Cummins: Manufacturer Overview

Cummins Inc. is a prominent manufacturer in the commercial truck industry, known for its wide range of high-quality automotive components. Founded in 1919, Cummins has built a reputation for innovation, reliability, and performance. The company offers a diverse product portfolio that includes engines, powertrains, and various aftermarket parts, all designed to meet the demanding requirements of commercial truck operations. Cummins’ commitment to quality and customer satisfaction has made it a trusted name in the industry 1.

Cummins Hexagon Head Cap Screw 181210 in V28 Engines

The Cummins Hexagon Head Cap Screw, part number 181210, is a critical component in the assembly and maintenance of V28 engines. This part is designed to provide secure fastening in various engine applications, ensuring that components remain tightly connected under operational stresses 2.

V28 Engine Series

In the V28 engine series, the 181210 Hexagon Head Cap Screw is utilized in several key areas. These engines are known for their robust design and high performance, often used in heavy-duty applications such as construction equipment, marine vessels, and industrial machinery. The screw’s design allows it to withstand the demanding conditions these engines operate under, including high temperatures and significant mechanical loads 1.

Application in V28 Engines

The 181210 screw is integral to the engine’s assembly process, securing various parts together. Its hexagonal head provides a larger surface area for tools, facilitating easier and more efficient tightening and loosening. This is particularly important in the V28 engines, where precise assembly is crucial for optimal performance and longevity 2.

Importance of the Part

The reliability of the 181210 Hexagon Head Cap Screw is paramount in V28 engines. Its use ensures that critical engine components are held firmly in place, preventing any potential loosening or failure during operation. This screw’s consistent performance is essential for maintaining the engine’s structural integrity and operational efficiency 1.

Compatibility and Usage

The 181210 screw is compatible with a range of V28 engine models, making it a versatile component in Cummins’ engine lineup. Its design and material properties make it suitable for use in various environments, from the rugged conditions of construction sites to the demanding marine settings. This compatibility ensures that the screw can be used across different V28 engine variants, providing a standardized solution for engine assembly and maintenance 2.

Role of Part 181210 Hexagon Head Cap Screw in Engine Systems

The part 181210 Hexagon Head Cap Screw is integral to the assembly and maintenance of various engine components. Its application spans across multiple critical areas, ensuring the structural integrity and operational efficiency of the engine system 1.

Base Parts

In the assembly of base parts, the 181210 screw is utilized to secure components that form the foundation of the engine. These parts often include mounting brackets, support structures, and ancillary equipment that require robust fastening solutions. The screw’s design allows for easy installation and removal, facilitating maintenance and upgrades 2.

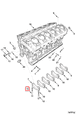

Cylinder Block

Within the cylinder block, the 181210 screw plays a significant role in attaching various covers and plates. These include the front and rear covers, which house essential components such as the crankshaft, pistons, and connecting rods. The screw ensures these covers are securely fastened, preventing any misalignment or movement that could lead to engine failure 1.

Cylinder Block Kit

When assembling a cylinder block kit, the 181210 screw is employed to fasten the block to the engine frame. This kit often includes the cylinder block, pistons, rings, and gaskets. Secure fastening is vital to maintain the precision alignment of these components, which is essential for the engine’s performance and longevity 2.

Cylinder Short Block

In a cylinder short block, which consists of the cylinder block, crankshaft, pistons, and connecting rods, the 181210 screw is used to attach ancillary components such as oil pans and valve covers. This ensures that all parts are held in place, contributing to the overall stability and functionality of the short block 1.

Cylinder Short V-12 Block

For the more complex cylinder short V-12 block, the 181210 screw is crucial in attaching the two cylinder banks to the engine frame. This block requires precise alignment and secure fastening to handle the increased power and stress, making the screw an essential component in its assembly 2.

Cylinder V-12 Block

Similarly, in a cylinder V-12 block, the screw is used to fasten the cylinder heads, intake manifolds, and exhaust manifolds. These components need to be securely attached to ensure optimal engine performance and to prevent any leaks or misalignments that could affect the engine’s efficiency 1.

Short Block Cylinder

In the short block cylinder, which includes the cylinder block, crankshaft, pistons, and connecting rods without the cylinder head, the 181210 screw is used to secure the oil pan and other ancillary components. This ensures that the short block remains stable and aligned during operation 2.

Short Block Engine Kit

When assembling a short block engine kit, which typically includes the cylinder block, pistons, rings, and gaskets, the 181210 screw is used to fasten the block to the engine frame and attach various covers and plates. This secure fastening is essential for the kit’s integrity and performance 1.

Subbase

Finally, in the subbase, which supports the engine and transmits its vibrations to the chassis, the 181210 screw is used to attach the engine to the subbase. This ensures that the engine is securely mounted, reducing the risk of movement or damage during operation 2.

Conclusion

The 181210 Hexagon Head Cap Screw is a vital component in the assembly and maintenance of commercial trucks and engines. Its robust design, durable material, and ease of use make it an essential part for ensuring secure and reliable fastening in various applications. Proper installation, regular maintenance, and understanding its role in engine systems are crucial for maximizing the performance and longevity of the components it secures.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.