This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins Hexagon Head Cap Screw, specifically Part #181211, is a vital component in the maintenance and assembly of commercial trucks. Cummins, a renowned manufacturer in the commercial vehicle industry, produces this screw to meet the demanding requirements of heavy-duty applications. This part is integral to ensuring the structural integrity and reliability of various truck components.

Basic Concepts of Hexagon Head Cap Screws

A Hexagon Head Cap Screw is a type of fastener characterized by its hexagonal head, which allows for efficient tightening and loosening using standard tools such as wrenches or sockets. The screw’s design includes a threaded shaft that engages with internal threads in the mating component, providing a secure and robust connection. These screws are commonly used in applications requiring high tensile strength and resistance to vibration 1.

Purpose of the 181211 Hexagon Head Cap Screw in Truck Operations

The 181211 Hexagon Head Cap Screw plays a significant role in the assembly and maintenance of commercial trucks. It is utilized in various truck components, including engine mounts, chassis assemblies, and body panels. By providing a strong and reliable fastening solution, this screw helps maintain the structural integrity of the truck, ensuring safety and performance under demanding conditions.

Key Features of the 181211 Hexagon Head Cap Screw

The 181211 Hexagon Head Cap Screw boasts several distinctive characteristics that enhance its effectiveness and durability. It is typically made from high-strength steel, offering superior tensile strength. The screw features a fine or coarse thread, depending on the application, which ensures a secure fit in the mating component. The hexagonal head design allows for easy installation and removal using common hand tools.

Benefits of Using the 181211 Hexagon Head Cap Screw

Utilizing the 181211 Hexagon Head Cap Screw offers several advantages. Its high-strength material composition provides enhanced durability and resistance to wear and tear. The screw’s design also offers excellent corrosion resistance, making it suitable for use in various environmental conditions. Additionally, the hexagonal head allows for easy installation and removal with standard tools, simplifying maintenance procedures 2.

Installation Guidelines

Proper installation of the 181211 Hexagon Head Cap Screw is crucial for ensuring optimal performance and longevity. Begin by selecting the appropriate size and type of screw for the application. Use a tap to create matching threads in the mating component if necessary. Insert the screw and tighten it using a wrench or socket, ensuring it is secure but not over-tightened to avoid damage. Regularly check the screw for proper torque to maintain a secure connection.

Troubleshooting Common Issues

Frequent problems associated with Hexagon Head Cap Screws include loosening and corrosion. To address loosening, ensure the screw is properly torqued during installation and periodically check its tightness. If corrosion is an issue, consider using a screw made from corrosion-resistant materials or applying a protective coating. Regular inspection and maintenance can help identify and resolve these issues promptly 3.

Maintenance Tips

Regular maintenance of the 181211 Hexagon Head Cap Screw can prolong its service life and maintain its functionality. Inspect the screw periodically for signs of wear, corrosion, or loosening. Clean the screw and surrounding area to remove any debris or contaminants that could affect performance. If necessary, reapply a protective coating to enhance corrosion resistance. Following these maintenance practices will help ensure the screw remains in optimal condition.

Cummins: A Brief Overview

Cummins Inc. is a leading manufacturer in the commercial vehicle industry, known for its high-quality engines, powertrains, and related technologies. Founded in 1919, Cummins has a long history of innovation and excellence. The company offers a wide range of products designed to meet the needs of various industries, including transportation, construction, and power generation. Cummins is recognized for its commitment to quality, reliability, and customer satisfaction.

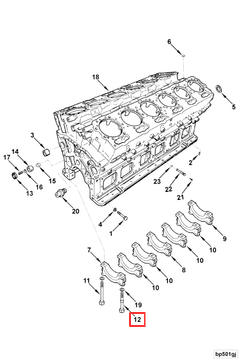

Cummins Hexagon Head Cap Screw 181211 in V28 Engines

The Cummins Hexagon Head Cap Screw part number 181211 is a critical component in the assembly and maintenance of V28 engines. This part is designed to provide secure fastening in various engine applications, ensuring that components remain tightly secured under operational stresses.

In V28 engines, the 181211 screw is often used in areas requiring robust and reliable fastening. Its hexagon head design allows for efficient torque application with common tools, facilitating ease of use during assembly and maintenance procedures. The material and construction of this screw are tailored to withstand the high temperatures and pressures typical in engine environments, ensuring durability and longevity.

The screw’s application in V28 engines includes securing engine blocks, cylinder heads, and other critical assemblies. Its use in these areas is crucial for maintaining the structural integrity and operational efficiency of the engine. The precise fit and functionality of the 181211 screw are essential for the overall performance and reliability of the V28 engine series.

Role of Part 181211 Hexagon Head Cap Screw in Engine Systems

The Part 181211 Hexagon Head Cap Screw is instrumental in securing and maintaining the integrity of various engine components. Its application spans across multiple critical areas within the engine assembly, ensuring that parts remain firmly in place under operational stress.

Base Parts

In the foundational structure of an engine, the base parts require robust fastening solutions to withstand vibrations and thermal expansions. The Hexagon Head Cap Screw provides the necessary tensile strength to keep these components securely attached, preventing any potential misalignment that could lead to operational inefficiencies or failures.

Cylinder Block

The cylinder block, being the core of the engine, demands precise assembly. The Hexagon Head Cap Screw is utilized to fasten various sub-components within the cylinder block, such as bearing caps and ancillary brackets. This ensures that the block maintains its structural rigidity and alignment, which is essential for the smooth operation of pistons and other moving parts.

Cylinder Block Kit

When assembling a cylinder block kit, which includes the cylinder block along with pistons, rings, and other necessary components, the Hexagon Head Cap Screw plays a significant role. It is used to secure the main caps, ensuring that the crankshaft is properly aligned and supported. This alignment is vital for the balanced rotation of the crankshaft, directly influencing the engine’s performance and longevity.

Cylinder Short Block and Cylinder Short V-12 Block

In both the cylinder short block and the cylinder short V-12 block, the Hexagon Head Cap Screw is employed to fasten the cylinder heads to the block. This connection is paramount for maintaining the seal between the combustion chambers and the coolant passages, preventing any leaks that could compromise engine efficiency.

Cylinder V-12 Block

For the more complex cylinder V-12 block, the Hexagon Head Cap Screw is crucial in securing the intricate network of components. It ensures that the V-configuration maintains its structural integrity, which is essential for the synchronized operation of the dual-bank cylinders.

Short Block Cylinder and Short Block Engine Kit

In the short block cylinder and the short block engine kit, which typically include the cylinder block, crankshaft, pistons, and connecting rods, the Hexagon Head Cap Screw is used extensively. It secures the main bearing caps to the block, ensuring that the crankshaft is held in place with precision. This is fundamental for the engine’s rotational dynamics and overall performance.

Subbase

The subbase, which supports the entire engine assembly, relies on the Hexagon Head Cap Screw to fasten it to the vehicle’s chassis. This connection is vital for absorbing engine vibrations and ensuring that the engine remains stable during operation.

Conclusion

In summary, the Part 181211 Hexagon Head Cap Screw is a versatile fastener that contributes to the structural integrity and operational efficiency of various engine components. Its role in securing and aligning these parts is indispensable for the reliable performance of the engine.

-

Automotive Technician Training Theory, Tom Denton and Hayley Pells, Routledge, 2022

↩ -

Technologies and Approaches to Reducing the Fuel Consumption of Medium and Heavy-Duty Vehicles, Andrew Brown Jr, National Academy of Sciences, 2010

↩ -

The Dynamic Behavior of a Diesel Engine, S. A. Miedema, Z. Lu, Published by Drir S. A. Miedema, 2010

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.