This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Flat Head Cap Screw Part #186792 by Cummins is a specialized fastener designed for use in commercial trucks. It is significant in the trucking industry due to its role in securing various components, ensuring the structural integrity and operational efficiency of the vehicle. Its primary applications include fastening parts in the engine, transmission, and chassis assemblies.

Basic Concepts of Flat Head Cap Screws

Flat head cap screws are a type of fastener characterized by a flat, countersunk head that sits flush with or below the surface of the material being fastened. They are commonly used in mechanical assemblies to secure components together while minimizing protrusion. The flat head design allows for a smooth surface finish, reducing the risk of snagging or interference with other parts. These screws function by threading into a pre-drilled hole, creating a secure connection between components 1.

Purpose of the 186792 Flat Head Cap Screw in Truck Operations

The 186792 Flat Head Cap Screw plays a specific role in the operation and maintenance of commercial trucks. It is utilized in various truck components, including engine mounts, transmission housings, and chassis brackets. By providing a strong, secure connection, this screw helps maintain the alignment and integrity of critical truck systems. Its design ensures that it can withstand the dynamic loads and vibrations encountered in heavy-duty applications 2.

Key Features of the 186792 Flat Head Cap Screw

The 186792 Flat Head Cap Screw is engineered with several key characteristics that make it suitable for heavy-duty applications. It is typically composed of high-strength materials such as alloy steel, which provides excellent durability and resistance to wear. The screw features a fine or coarse thread, depending on the application, allowing for a secure fit in various materials. Its design specifications include a hex socket or Phillips drive for easy installation and removal.

Benefits of Using the 186792 Flat Head Cap Screw

Utilizing the 186792 Flat Head Cap Screw in truck maintenance and assembly offers several advantages. Its high-strength material composition ensures durability under heavy loads. The screw’s design provides resistance to vibration, reducing the likelihood of loosening over time. Additionally, the flat head allows for a low-profile installation, which is beneficial in applications where space is limited. The ease of installation, thanks to its drive type, further enhances its practicality in maintenance scenarios 3.

Installation Guidelines

Proper installation of the 186792 Flat Head Cap Screw is crucial for optimal performance and longevity. Begin by ensuring the mating surfaces are clean and free of debris. Use a tap to create a threaded hole if necessary. Align the screw with the hole and drive it in using the appropriate tool, ensuring it is tightened to the manufacturer’s specified torque. Avoid over-tightening, as this can lead to stripping or damage to the screw or the material being fastened.

Troubleshooting Common Issues

Common problems associated with flat head cap screws include loosening and corrosion. To address loosening, verify that the screw was installed to the correct torque specification and that the mating surfaces are free of vibrations that could cause it to unscrew. For corrosion, regularly inspect the screw and surrounding areas. Applying a corrosion-resistant coating or using stainless steel screws in corrosive environments can help mitigate this issue.

Maintenance Tips

Regular maintenance practices can prolong the life of the 186792 Flat Head Cap Screw. Inspect screws periodically for signs of wear, corrosion, or loosening. Replace screws that show significant wear or damage. Additionally, ensure that all fasteners are tightened to the manufacturer’s specifications during routine maintenance checks. Keeping the screw and surrounding areas clean will also help prevent corrosion and ensure long-term reliability.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation in the commercial truck industry for producing reliable and high-performance components. The company’s extensive product range includes engines, powertrains, and aftermarket parts, all designed to meet the demanding requirements of heavy-duty applications. Cummins components, including the 186792 Flat Head Cap Screw, are trusted by professionals for their quality, durability, and performance.

Cummins Flat Head Cap Screw 186792 in Engine Applications

The Cummins Flat Head Cap Screw part number 186792 is a critical component in various engine configurations, ensuring secure fastening and stability. This part is integral to the assembly and maintenance of several Cummins engine models.

B4.5 RGT Engines

In the B4.5 RGT engines, the 186792 Flat Head Cap Screw is used in several key areas. It plays a vital role in securing various engine components, ensuring that they remain tightly fastened and properly aligned during operation. This screw is often found in applications where high strength and durability are required, such as in the cylinder head assembly and other critical junctures within the engine.

The use of this part in the B4.5 RGT engines highlights its importance in maintaining the integrity and performance of the engine. Its design and material properties are specifically chosen to withstand the demanding conditions of engine operation, providing reliable performance over time.

The 186792 Flat Head Cap Screw is essential for the proper assembly and maintenance of the B4.5 RGT engines, ensuring that all components are securely fastened and properly aligned. This contributes to the overall reliability and efficiency of the engine, making it a crucial component in the engine’s design.

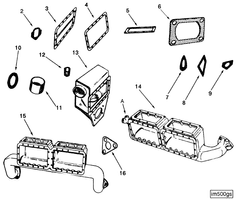

Part 186792 Flat Head Cap Screw Component Usage

The Part 186792 Flat Head Cap Screw is integral to the assembly and secure operation of various engine components.

In the air intercooler system, this screw is utilized to fasten the intercooler to its mounting brackets. This ensures that the intercooler remains securely in place, allowing for efficient cooling of the compressed air from the turbocharger before it enters the engine. Proper fastening is essential to maintain the structural integrity and performance of the intercooler.

For the fuel pump, the Flat Head Cap Screw is employed to secure the fuel pump module within the fuel tank. This connection is vital for maintaining the pump’s position and ensuring a stable fuel supply to the engine. It also helps in preventing any potential leaks that could arise from an improperly secured fuel pump.

In the intake manifold, this screw plays a role in attaching the manifold to the engine block. A secure attachment is necessary to ensure a proper seal, which is critical for optimal air-fuel mixture distribution to the cylinders. This, in turn, enhances engine performance and efficiency.

Lastly, when mounting the intercooler, the Flat Head Cap Screw is used to connect the intercooler to the vehicle’s chassis or other supporting structures. This ensures that the intercooler is held firmly in place, reducing vibrations and maintaining the efficiency of the cooling process.

Overall, the Part 186792 Flat Head Cap Screw is a fundamental component in ensuring the secure and efficient operation of these engine systems.

Conclusion

The 186792 Flat Head Cap Screw by Cummins is a vital component in the assembly and maintenance of commercial trucks and Cummins engines. Its design and material properties ensure durability, resistance to vibration, and secure fastening of critical components. Proper installation, regular maintenance, and understanding its applications are essential for maximizing the performance and longevity of this part in heavy-duty applications.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.