This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 205199 Twelve Point Cap Screw is a specialized fastener designed for use in commercial truck applications. It is engineered to provide secure and reliable fastening solutions, ensuring the integrity and performance of various truck components. Its significance lies in its ability to withstand the demanding conditions encountered in heavy-duty truck operations, contributing to the overall reliability and safety of the vehicle 1.

Basic Concepts of Twelve Point Cap Screws

A twelve point cap screw is a type of fastener that features a hexagonal socket with twelve sides instead of the standard six. This design offers several advantages over traditional cap screws, including improved torque application and reduced risk of cam-out. In the automotive industry, twelve point cap screws are commonly used in applications where high torque and secure fastening are required, such as in engine components, transmission systems, and chassis assemblies 2.

Purpose and Role in Truck Operation

The Cummins 205199 Twelve Point Cap Screw plays a vital role in the operation and maintenance of commercial trucks. It is utilized in various truck components, including engine mounts, transmission housings, and chassis brackets. By providing a secure and stable connection, this cap screw helps maintain the structural integrity of these components, ensuring optimal performance and longevity of the truck. Its applications extend to both original equipment manufacturing (OEM) and aftermarket parts, making it a versatile choice for truck maintenance and repair 3.

Key Features

The Cummins 205199 Twelve Point Cap Screw is characterized by several key features that enhance its performance and durability. Its twelve-sided socket design allows for better torque application and reduces the likelihood of cam-out, ensuring a more secure fastening. The screw is typically made from high-strength materials, such as alloy steel, which provides excellent resistance to corrosion and wear. Additionally, it may feature a zinc-plated or black oxide finish to further protect against environmental factors and improve longevity 4.

Benefits

The Cummins 205199 Twelve Point Cap Screw offers several benefits that make it an ideal choice for commercial truck applications. Its unique twelve-sided design allows for more precise torque application, reducing the risk of over-tightening or stripping. This results in improved fastening security and reliability. Additionally, the enhanced torque application capability minimizes the risk of cam-out, ensuring a more consistent and secure connection. The durable material composition and protective finishes contribute to the screw’s longevity, making it a cost-effective solution for truck maintenance 5.

Installation Guidelines

Proper installation of the Cummins 205199 Twelve Point Cap Screw is crucial to ensure optimal performance and longevity. To install the screw, use a compatible twelve-sided socket wrench to apply the recommended torque specifications. It is important to use the correct tools and techniques to avoid damaging the screw or the surrounding components. Ensure that the mating surfaces are clean and free of debris before installation to promote a secure connection. Regularly inspect the screw for signs of wear or damage and replace it as necessary to maintain the integrity of the truck’s components 6.

Troubleshooting and Maintenance

Common issues that may arise with twelve point cap screws include loosening, corrosion, and wear. To troubleshoot these issues, regularly inspect the screws for signs of damage or deterioration. If a screw appears loose, re-tighten it to the recommended torque specifications using a twelve-sided socket wrench. In cases of corrosion, clean the affected area and apply a corrosion-resistant coating to prevent further degradation. Replace any screws that show significant wear or damage to ensure continued reliable performance. Regular maintenance and inspection will help prolong the lifespan of the screws and maintain the integrity of the truck’s components 7.

Safety Considerations

When working with twelve point cap screws, it is important to observe several safety practices to prevent accidents and ensure user safety. Always wear appropriate personal protective equipment (PPE), such as gloves and safety glasses, when handling and installing the screws. Use the correct tools and techniques to avoid damaging the screws or surrounding components. Store the screws in a dry, cool place to prevent corrosion and degradation. Follow all manufacturer recommendations and guidelines for torque specifications and installation procedures to ensure a secure and reliable connection 8.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the commercial truck industry. The company is committed to providing reliable and high-performance components that meet the demanding requirements of heavy-duty truck applications. Cummins’ dedication to excellence and continuous improvement ensures that their products, including the Cummins 205199 Twelve Point Cap Screw, deliver exceptional performance and durability in commercial truck operations 9.

Compatibility with Cummins Engines

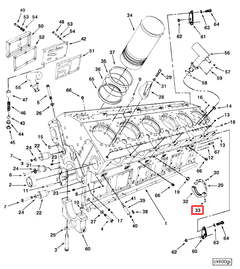

The Twelve Point Cap Screw, part number 205199, manufactured by Cummins, is a critical component in various engine assemblies. This screw is designed to provide robust fastening in applications that require high strength and durability.

K38 and K50 Engines

In the K38 and K50 engines, the 205199 cap screw is utilized in several key areas. These engines, known for their reliability and performance, often incorporate this screw in the cylinder head assembly. The cap screw ensures that the cylinder head is securely fastened to the engine block, maintaining the integrity of the combustion chamber and preventing leaks. Additionally, it is used in the valve train mechanism, where it helps to secure various components, ensuring smooth and reliable engine operation 10.

M11 MECHANICAL Engine

The M11 MECHANICAL engine also benefits from the use of the 205199 cap screw. This engine, designed for heavy-duty applications, employs the screw in its robust construction. In the M11 MECHANICAL engine, the 205199 cap screw is often found in the engine block assembly, where it helps to secure the main bearing caps and other critical components. This ensures that the engine maintains its structural integrity under high stress conditions, contributing to the engine’s overall durability and performance 11.

Common Applications

Across these engines, the 205199 cap screw is a versatile component, often used in the following applications:

- Cylinder Head Fastening: Ensuring a tight seal and proper alignment of the cylinder head.

- Valve Train Assembly: Securing components such as rocker arms and push rods.

- Engine Block Assembly: Attaching main bearing caps and other critical engine components.

The use of the 205199 cap screw in these engines underscores its importance in maintaining the structural integrity and performance of Cummins engines. Its high strength and durability make it an essential component in the assembly of these robust engines 12.

Role of Part 205199 Twelve Point Cap Screw in Engine Systems

The Part 205199 Twelve Point Cap Screw is integral to the secure assembly and operation of various engine components. It is utilized in the Assembly Cylinder Block to ensure that the Cylinder Block Assembly and Cylinder Block are tightly fastened, maintaining structural integrity and preventing leaks.

In the Short Block Assy. - K50G3 and Short Block Assy. - K38, this cap screw plays a significant role in securing the Base Part and Base Parts, which are foundational elements in the engine’s architecture. It is also essential in the Block Cylinder Kit and Cylinder Short Block, where it helps in maintaining the precise alignment and fastening of components.

For the Engine Oil Cooler and Fan Clutch to Adapt., the Twelve Point Cap Screw ensures that these components are securely attached to the engine, allowing for efficient operation and heat management. In the Fan Drive Arra and Keel Cooling Kit, it provides the necessary tension and stability required for optimal performance.

The Jacobs Brake system also benefits from the secure fastening provided by this cap screw, ensuring that the brake components are reliably attached and function correctly. In the Long Block Assy. - 50, it contributes to the overall stability and integrity of the assembly.

Additionally, in the Lubricating Oil Filter and Main Bearing Shell, the cap screw ensures that these critical components are properly mounted, facilitating smooth operation and longevity of the engine.

In the Short Block Assembly - 50 and Short Block Assy -K50, it is used to fasten various parts, ensuring that the short block remains a cohesive unit. The Spacer, Fan Pilot and Torque Converter Cooler also rely on this cap screw for secure attachment, contributing to the efficient transfer of power and cooling.

Lastly, in the Water By-Pass Tube, the Twelve Point Cap Screw ensures that the tube is firmly in place, allowing for proper water flow and temperature regulation within the engine system 13.

Conclusion

The Cummins 205199 Twelve Point Cap Screw is a critical component in the assembly and maintenance of commercial truck engines. Its unique design, high-strength materials, and durable finishes make it an ideal choice for applications requiring secure and reliable fastening. Proper installation, regular maintenance, and adherence to safety practices are essential to ensure the optimal performance and longevity of this part. Cummins’ commitment to quality and innovation ensures that the 205199 cap screw continues to deliver exceptional performance and durability in heavy-duty truck operations.

-

Kluczyk, B. (2008). How to Rebuild Any Automotive Engine. CarTech.

↩ -

Watson, B. (2011). Mobile Equipment Hydraulics A Systems and Troubleshooting Approach. Cengage Learning.

↩ -

Fischer, R., Kucukay, F., Jurgens, G., Najork, R., & Pollak, B. (2015). The Automotive Transmission Book Powertrain. Springer.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for ISF3.8 CM2220 F116. Bulletin Number 4383667.

↩ -

Kluczyk, B. (2008). How to Rebuild Any Automotive Engine. CarTech.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for ISF3.8 CM2220 F116. Bulletin Number 4383667.

↩ -

Watson, B. (2011). Mobile Equipment Hydraulics A Systems and Troubleshooting Approach. Cengage Learning.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for ISF3.8 CM2220 F116. Bulletin Number 4383667.

↩ -

Cummins Inc. (n.d.). Company Overview. Retrieved from Cummins Official Website.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for ISF3.8 CM2220 F116. Bulletin Number 4383667.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for ISF3.8 CM2220 F116. Bulletin Number 4383667.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for ISF3.8 CM2220 F116. Bulletin Number 4383667.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for ISF3.8 CM2220 F116. Bulletin Number 4383667.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.