205323

Twelve Point Cap Screw

Cummins®

AVAILABLE

8 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Twelve Point Cap Screw, Part #205323 by Cummins, is a specialized fastener designed for use in commercial trucks. This component is vital for securing various parts within the truck’s structure, ensuring stability and reliability under demanding conditions. Understanding its purpose and function is key to maintaining the integrity and performance of commercial vehicles.

Basic Concepts of Twelve Point Cap Screws

A twelve point cap screw is characterized by its hexagonal socket head, which allows for increased torque application compared to traditional hex-head screws. This design reduces the likelihood of cam-out during tightening or loosening. Unlike other fasteners, the twelve point design offers a more secure grip for tools, enhancing efficiency and safety during installation and removal. The mechanics behind twelve point cap screws involve a precise thread design that ensures a strong, durable connection between components 1.

Role of the 205323 Twelve Point Cap Screw in Truck Operation

This Cummins part plays a significant role in the operation and maintenance of commercial trucks by securing critical components that are subject to vibration and stress. It is commonly used in applications where high torque and resistance to loosening are required, such as in the attachment of engine components, chassis parts, and other structural elements. By providing a secure connection, this screw helps maintain the alignment and integrity of these components, contributing to the overall safety and performance of the truck 2.

Key Features

The 205323 Twelve Point Cap Screw is crafted from high-strength materials, ensuring durability and reliability in demanding environments. Its thread design is optimized for maximum holding power, while special coatings or treatments may be applied to enhance corrosion resistance and reduce friction during installation. These features make it well-suited for the rigors of commercial truck operation, where components are exposed to a wide range of environmental conditions and mechanical stresses 3.

Benefits

Utilizing the 205323 Twelve Point Cap Screw offers several advantages, including improved torque application due to its unique head design, which minimizes the risk of cam-out. Its resistance to loosening under vibration ensures that critical connections remain secure over time, reducing the need for frequent maintenance. Additionally, the screw’s durability in harsh environments contributes to the longevity of truck components, enhancing overall vehicle reliability.

Troubleshooting and Maintenance

To ensure the longevity and proper function of the 205323 Twelve Point Cap Screw, it is important to monitor for signs of wear, corrosion, or failure. Regular inspections can help identify issues early, allowing for timely replacement or repair. Maintenance tips include using the appropriate tools for installation and removal to avoid damage to the screw head, and applying the correct torque specifications to prevent over-tightening or under-tightening, which can lead to component failure.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a rich history in the commercial truck industry, Cummins is committed to innovation and quality in manufacturing components that enhance the performance and reliability of commercial vehicles. Their dedication to excellence is evident in the design and production of the 205323 Twelve Point Cap Screw, a testament to their expertise in creating durable, high-performance fasteners for the trucking industry.

Twelve Point Cap Screw (Part 205323) in Cummins Engines

The Twelve Point Cap Screw, part number 205323, manufactured by Cummins, is a critical component in various Cummins engine models. This screw is designed to provide robust fastening, ensuring secure connections in high-stress environments typical of engine assemblies.

K19 and K38 Engines

In the K19 and K38 engines, the Twelve Point Cap Screw is utilized in several key areas. These engines, known for their reliability and efficiency, incorporate the 205323 screw to maintain structural integrity and operational safety. The screw’s design allows for precise torque application, which is essential for maintaining the alignment and stability of engine components under varying operational conditions.

K50 Engine

The K50 engine also benefits from the use of the Twelve Point Cap Screw. This engine, designed for heavy-duty applications, requires components that can withstand significant mechanical stress. The 205323 screw is strategically placed to secure various parts, ensuring that the engine can operate efficiently and reliably even in demanding environments.

N14 CELECT PLUS and N14 MECHANICAL Engines

For the N14 CELECT PLUS and N14 MECHANICAL engines, the Twelve Point Cap Screw plays a vital role in maintaining the integrity of the engine’s structure. These engines, known for their durability and performance, utilize the 205323 screw in critical fastening applications. The screw’s twelve-point design provides better grip and reduces the likelihood of rounding off, which is crucial for the longevity and performance of these engines.

The consistent use of the Twelve Point Cap Screw across these engines highlights its importance in ensuring the reliability and efficiency of Cummins engine systems.

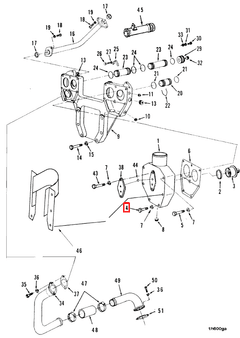

Part 205323 Twelve Point Cap Screw Component Usage

The Part 205323 Twelve Point Cap Screw is integral to the secure assembly and operation of various engine components. Its application spans across multiple critical areas, ensuring the integrity and functionality of the engine system.

Actuator Bracket Mounting

In the actuator bracket mounting, the Twelve Point Cap Screw provides the necessary tension and stability. This ensures that the actuator remains firmly in place, allowing for precise control over engine functions.

Fuel System Components

For fuel connections and fuel tubing, the screw plays a role in maintaining the integrity of the fuel lines. It secures connections, preventing leaks and ensuring a consistent fuel supply to the engine.

Water Outlet and Thermostat Housing

At the water outlet connection and within the thermostat housing, the screw helps in sealing and securing components. This is vital for maintaining the engine’s cooling system efficiency, preventing coolant leaks, and ensuring stable engine temperatures.

Front Engine Support and Gear Housing

In the front engine support and gear housing mounting cover, the screw contributes to the structural stability of these components. It ensures that the gear housing remains aligned and securely attached, which is essential for the smooth operation of the engine’s moving parts.

Cylinder Head and Housing

When used in the cylinder head and housing, the screw aids in maintaining the seal and structural integrity of these components. This is important for preventing gas leaks and ensuring optimal combustion within the engine cylinders.

Injector and Oil Control Valve Mounting

For mounting injectors and oil control valves, the screw ensures these components are securely fastened. This is essential for the precise delivery of fuel and oil, contributing to the engine’s performance and efficiency.

Turbocharger and Auxiliary Pump

In the context of turbochargers and auxiliary pumps, the screw helps in securing these high-performance parts. This ensures they operate under the correct conditions, contributing to the engine’s overall performance and reliability.

Thermostat and Support Assembly Housing

Finally, in the thermostat and support assembly housing, the screw plays a part in securing these components, which are crucial for regulating engine temperature and ensuring the engine operates within its optimal temperature range.

Overall, the Part 205323 Twelve Point Cap Screw is a versatile component that enhances the reliability and performance of various engine systems through secure fastening and structural integrity.

Conclusion

The 205323 Twelve Point Cap Screw by Cummins is a critical component in the maintenance and operation of commercial trucks and Cummins engines. Its unique design, high-strength materials, and resistance to loosening under vibration make it an indispensable part for securing critical components in demanding environments. Regular maintenance and proper use of this part ensure the longevity and reliability of truck and engine systems, contributing to the overall performance and safety of commercial vehicles.

-

Automotive Lubricants Reference Book, Arthur J Caines, Roger F Haycock and John E Hillier, SAE International, 2004

↩ -

Modern Diesel Technology: Light Duty Diesels, Sean Bennett, Cengage Learning, 2012

↩ -

Critical Component Wear in Heavy Duty Engines, P. A. Lakshminarayanan and Nagaraj S. Nayak, John Wiley & Sons, 2011

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.