This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

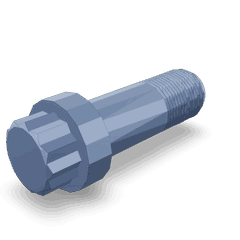

The 205680 Twelve Point Cap Screw, manufactured by Cummins, is a specialized fastener designed for use in commercial truck applications. Cummins, a well-established name in the automotive and heavy-duty truck industry, produces this part to meet the demanding requirements of truck operations. This screw plays a role in ensuring the reliability and efficiency of commercial trucks.

Basic Concepts of Twelve Point Cap Screws

A twelve point cap screw is a type of fastener characterized by its hexagonal socket head, which provides twelve points of contact. This design allows for better torque application and reduces the risk of cam-out compared to traditional six-point screws. In the automotive industry, twelve point cap screws are commonly used in applications where high torque and secure fastening are required 1.

Purpose and Role in Truck Operation

This Cummins part is specifically designed to secure various components within commercial trucks. Its role is to provide a strong and reliable connection, ensuring that parts remain firmly in place under the stress of heavy-duty operations. This contributes to the overall functionality and safety of the vehicle by maintaining the integrity of critical assemblies.

Key Features

The 205680 features a robust design with a twelve-point socket head, allowing for efficient torque application. It is made from high-quality materials, ensuring durability and resistance to wear. The screw’s unique characteristics include enhanced grip and reduced likelihood of stripping, making it suitable for demanding applications 2.

Benefits

The advantages of using the 205680 include improved torque application, which allows for tighter and more secure fastening. The design reduces the risk of cam-out, providing a more stable connection. Additionally, its durability ensures long-lasting performance in heavy-duty applications, contributing to the overall reliability of the truck.

Installation and Usage Guidelines

Proper installation of the 205680 involves several steps. Begin by ensuring the mating surfaces are clean and free of debris. Use a torque wrench to apply the specified torque, which ensures a secure connection without over-tightening. Follow recommended practices to maintain the integrity of the fastener and the connected components.

Troubleshooting and Maintenance

Common issues with the 205680 may include loosening over time or damage from excessive torque. Regular inspection and maintenance can help identify and address these problems. If loosening is detected, re-torque the screw to the specified value. For damaged screws, replacement may be necessary to ensure continued reliability.

Cummins: A Brief Overview

Cummins Inc. is a leading manufacturer in the automotive and heavy-duty truck industry, known for its commitment to quality and innovation. With a diverse product range, Cummins has established a reputation for producing reliable and high-performance components. The company’s dedication to excellence is evident in its manufacturing processes and the durability of its products 3.

Twelve Point Cap Screw 205680 in Cummins Engines

The 205680, manufactured by Cummins, plays a role in the assembly and operation of several Cummins engine models. This part is used for securing various components within the engine, ensuring structural integrity and operational efficiency.

K38 and K50 Engines

In the K38 and K50 engines, the 205680 is utilized in several key areas. It is often found in the engine block, where it helps to secure the cylinder heads, ensuring a tight seal and preventing leaks. Additionally, this screw is used in the mounting of ancillary components such as the alternator and the fuel injection pump, providing the necessary stability and alignment for optimal performance.

V903 Engine

For the V903 engine, the 205680 is integral to the engine’s overall assembly. It is commonly used in the engine block to attach various sub-assemblies, such as the intake and exhaust manifolds. This screw ensures that these components are securely fastened, which is crucial for maintaining the engine’s performance and longevity. Furthermore, it is also used in the mounting of the turbocharger, where precise alignment and secure fastening are paramount.

Common Applications

Across these engines, the 205680 is often employed in applications that require high strength and resistance to vibration. Its twelve-point design provides a better grip and more uniform distribution of torque, which is essential for maintaining the integrity of the connections in high-stress environments. This screw’s robust construction and precise engineering make it a reliable choice for critical engine components.

Part 205680 Twelve Point Cap Screw Component Usage

The 205680 is integral to the assembly and functionality of several key components within engine systems. Its application ensures secure fastening and reliable operation across various engine subsystems.

In the hydraulic pump drive system, the Twelve Point Cap Screw is used to fasten components that transfer power from the engine to the hydraulic pump. This secure attachment is essential for maintaining the integrity of the drive mechanism, ensuring efficient power transmission and minimizing the risk of component misalignment or failure.

For the pump and alternator drive, the screw plays a role in securing the drive components that connect the engine to both the pump and the alternator. This ensures that the engine can effectively power these auxiliary systems, contributing to the overall efficiency and reliability of the engine’s electrical and hydraulic functions.

In the rear gear drive system, the Twelve Point Cap Screw is employed to fasten gears and housing components. This secures the rear drive mechanism, allowing for smooth and consistent power transfer to the rear components of the engine system.

The rear hydraulic pump and its associated drive also benefit from the use of this screw. It ensures that the pump is firmly attached to its drive mechanism, facilitating efficient fluid transfer and maintaining the hydraulic system’s performance.

The shipping bracket utilizes the Twelve Point Cap Screw to secure the bracket to the engine frame. This is vital for transporting the engine, as it ensures that all components remain firmly in place during shipping, preventing damage and ensuring the engine arrives in optimal condition.

In the support structures of the engine, particularly those associated with the front engine components, the screw is used to fasten support brackets and housings. This provides a stable foundation for the front engine components, enhancing the engine’s structural integrity and operational stability.

Overall, the 205680 is a fundamental component in the secure assembly and reliable operation of various engine subsystems, contributing to the engine’s overall performance and durability.

Conclusion

The 205680 Twelve Point Cap Screw is a critical component in the assembly and operation of commercial trucks and Cummins engines. Its robust design, high-quality materials, and precise engineering ensure secure fastening and reliable performance in demanding applications. Proper installation, regular maintenance, and understanding its role in various engine subsystems are essential for maximizing the efficiency and longevity of the vehicle.

-

Technologies and Approaches to Reducing the Fuel Consumption of Medium and Heavy-Duty Vehicles, Andrew Brown Jr, National Academy of Sciences, 2010

↩ -

Diesel Mechanics, First Edition, Frank Sander, Global Media, 2007

↩ -

Engine Oils and Automotive Lubrication Mechanical Engineering Book 80, Wilfried J Bartz, CRC Press, 2019

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.